- Afirika

- Chialubaniya

- Chiamharic

- Chiarabu

- Chiameniya

- Chiazerbaijani

- Basque

- Chibelarusi

- Chibengali

- Chibosnia

- Chibugariya

- Chikatalani

- Cebuano

- China

- China (Taiwan)

- Chikosikani

- Chikroatia

- Chicheki

- Chidanishi

- Chidatchi

- Chingerezi

- Chiesperanto

- Chiestonia

- Chifinishi

- Chifalansa

- Chifrisian

- Chigalikiya

- Chijojiya

- Chijeremani

- Chigriki

- Chigujarati

- Chikiliyo cha ku Haiti

- hausa

- Hawaii

- Chiheberi

- Ayi

- Miao

- Chihangare

- Chi Icelandic

- igbo

- Chi Indonesian

- ayi

- Chitaliyana

- Chijapani

- Chijavani

- Kanada

- kazakh

- Khmer

- Rwanda

- Chikorea

- Chikurdi

- Kyrgyz

- Ntchito

- Chilatini

- Chilativiya

- Chilithuania

- ChiLuxembourgish

- Chimakedoniya

- Malgashi

- Chimalayi

- Malayalam

- Chimalta

- Chimaori

- Chimarathi

- Chimongoliya

- Myanmar

- Chinepali

- Chinorwe

- Chinorwe

- Occitan

- Pashto

- Chiperisi

- Chipolishi

- Chipwitikizi

- Chipunjabi

- Chiromania

- Chirasha

- Chisamoa

- Scottish Gaelic

- Chisebiya

- Chingerezi

- Chishona

- Sindi

- Sinhala

- Chisilovaki

- Chisiloveniya

- Somalia

- Chisipanishi

- Chisundanese

- Swahili

- Chiswidishi

- Chitagalogi

- Tajiki

- Tamil

- Chitata

- Telugu

- Thai

- Turkey

- Turkmen

- Chiyukireniya

- Chiurdu

- Uighur

- Chiuzbeki

- Vietnamese

- Chiwelesi

- Thandizeni

- Chiyidi

- Chiyoruba

- Chizulu

Mar . 10, 2025 13:53 Bwererani ku mndandanda

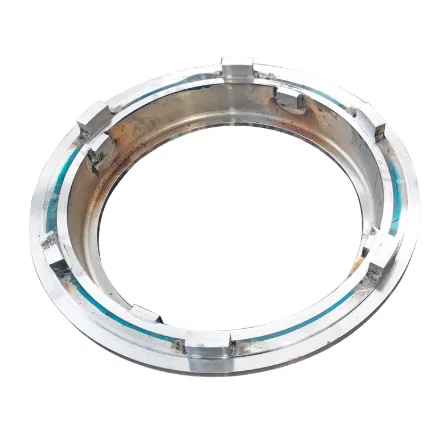

Applications of Cast Iron Pipe Mold Pallets in Water Systems

In the production of pipes used for water and sewage systems, the quality and durability of the mold pallets play a pivotal role. Among the most essential components for ensuring precision and strength in pipe production are cast iron pipe mold pallets and ductile iron pipe mould pallets. These specialized pallets offer the ideal solution for shaping pipes that must withstand extreme environmental conditions, such as pressure, temperature fluctuations, and heavy usage. Let’s explore how cast iron pipe mold pallets and ductile iron pipe mould pallets contribute to the creation of robust pipes for critical infrastructure like water distribution and sewage systems.

Cast Iron Pipe Mold Pallets:Durability and Strength for Heavy-Duty Applications

When it comes to manufacturing pipes for water and sewage systems, the strength and durability of the molds are paramount. Cast iron pipe mold pallets and ductile iron pipe mould pallets are designed to withstand the rigorous demands of pipe production. These pallets provide the necessary support to prevent deformation during the casting process, ensuring that the pipes retain their exact shape and structural integrity.

The inherent strength of ductile iron pipe mould pallets makes them particularly suitable for high-pressure applications commonly found in sewage systems. The pressure exerted by the wet concrete mix requires a pallet that can endure constant stress without compromising the mold's shape. The superior durability of cast iron pipe mold pallets ensures that the pipes produced are reliable and capable of handling the heavy demands of sewage and water systems, both underground and aboveground.

Cast Iron Pipe Mold Pallets:Ensuring Consistency and Precision in Pipe Production

Cast iron pipe mould pallets and ductile iron pipe mold pallets are designed to produce uniform and high-quality pipes. In industries like water and sewage management, precise dimensions are crucial for ensuring proper fittings, structural stability, and optimal flow efficiency. These pallets provide the consistency needed to ensure that each pipe meets strict industry standards.

The accuracy of the mold helps manufacturers avoid errors in pipe fitting, which can lead to costly repairs and replacements. Whether it's ductile iron pipe mould pallets used for pressure pipes in sewage systems or cast iron pipe mold pallets for water distribution, the ability to produce pipes with exact measurements ensures that they function as designed for years, reducing the risk of leaks or breaks in the system.

Cast Iron Pipe Mold Pallets:Weather Resistance and Longevity for Harsh Environments

Pipes used in water and sewage systems are often exposed to extreme weather conditions, including freezing temperatures, intense heat, and corrosive environments. For this reason, cast iron pipe mold pallets and ductile iron pipe mould pallets are engineered to be highly resistant to these environmental factors. Both types of pallets are designed to produce pipes that can endure harsh conditions without deteriorating or losing their strength.

Cast iron pipe mold pallets are resistant to corrosion, which is especially important in the production of pipes for sewage systems that are constantly in contact with water and organic materials. Ductile iron pipe mould pallets are equally beneficial as they offer improved flexibility and resilience, which makes them ideal for manufacturing pipes that must endure the expanding and contracting effects of ground movement or extreme temperatures. This durability ensures that the pipes retain their structural integrity over time, even when subjected to environmental stresses.

Cost-Efficiency in Pipe Mould Pallets

The use of cast iron pipe mold pallets and ductile iron pipe mould pallets not only improves the quality of the pipes but also contributes to the cost-efficiency of the manufacturing process. These pallets are long-lasting and require minimal maintenance, which reduces the frequency of replacement and repair costs. Additionally, the enhanced precision provided by these molds reduces the number of defective pipes, minimizing waste and rework.

By investing in durable ductile iron pipe mould pallets and cast iron pipe mold pallets, manufacturers can increase their output while ensuring that each pipe is produced to the highest standards. The reduced need for replacements and the improved efficiency in production lead to significant savings in the long run.

Whether for water distribution or sewage management, ductile iron pipe mould pallets and cast iron pipe mold pallets are versatile enough to accommodate a wide range of pipe sizes. The flexibility of these molds enables manufacturers to produce pipes of varying diameters and lengths, depending on the requirements of the project.

This adaptability is particularly useful in the production of specialized pipes for different sections of water and sewage systems. From large-diameter pipes designed to handle high volumes of water to smaller pipes used for residential systems, ductile iron pipe mould pallets and cast iron pipe mold pallets offer the precision and durability needed to meet diverse specifications.

In conclusion, cast iron pipe mold pallets and ductile iron pipe mould pallets are essential tools in the production of reliable pipes for water and sewage systems. Their exceptional durability, precision, and ability to withstand environmental stress make them indispensable in manufacturing high-quality pipes that ensure the safety and efficiency of infrastructure projects. By investing in these robust and cost-effective mold pallets, manufacturers can achieve greater operational efficiency while producing pipes that meet the stringent demands of modern water and sewage systems.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

NkhaniJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

NkhaniJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

NkhaniJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

NkhaniJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

NkhaniJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

NkhaniJun.24,2025