The foundation of modern urban water systems lies in the reliability of water distribution infrastructure. Among these critical components, cast iron water main pipe systems have proven indispensable for delivering safe drinking water across cities worldwide. For over a century, these durable conduits have formed the backbone of municipal water networks, combining structural integrity with corrosion resistance that outperforms many modern alternatives.

Shijiazhuang Casting Trading Co., Ltd.

Expertise in DIN EN877 Cast Iron Pipe Manufacturing Since 2005

Materials Engineering: Cast vs. Ductile Iron

The fundamental difference between traditional centrifugally cast iron and modern ductile iron lies in microstructure. While standard cast iron contains graphite flakes that can create stress concentration points, ductile iron undergoes magnesium treatment that transforms graphite into spheroidal formations. This molecular rearrangement provides ductile iron with remarkable flexibility and impact resistance. Industry studies from the Water Research Foundation indicate that ductile iron pipe offers tensile strength 3 times greater than traditional cast alternatives, a critical factor in seismic zones and deep burial applications.

Installation techniques differ significantly as well. The traditional bell and spigot ductile iron pipe joints provide leak-resistant connections through rubber gaskets compressed when the spigot end inserts into the bell end. This sealing technology achieves watertight integrity capable of withstanding pressures up to 350 psi while accommodating slight angular deflection during installation. For specialized applications requiring specific joint orientations or restrained connections, alternative joining methods like mechanical joints, flanges, or grooved couplings are available.

Technical Specifications and Performance Metrics

Understanding the technical parameters of cast iron water main pipe is essential for proper system design. The following table details critical specifications according to international standards including DIN EN877 and BS EN877:

| Parameter | Gray Cast Iron | Ductile Iron | Test Standard |

|---|---|---|---|

| Tensile Strength | ≥ 150 MPa | ≥ 420 MPa | ISO 945-1 |

| Yield Strength | N/A | ≥ 300 MPa | ISO 6892-1 |

| Elongation | 0.5% max | ≥ 10% | ISO 6892-1 |

| Pressure Rating (DN150) | 20 bar | 40 bar | EN 545 |

| Maximum Diameter | DN 600 | DN 2000 | EN 877 |

| Corrosion Resistance | Epoxy coating | Polyurethane lining | EN 14901 |

| Service Life | 50-70 years | 100+ years | ISO 10845 |

Performance data shows that properly installed cast iron water main pipe systems demonstrate exceptional longevity. In fact, research from the American Water Works Association reports many century-old installations continue functioning effectively today. Our centrifugally cast iron pipe production consistently exceeds minimum requirements, featuring epoxy resin coatings that reduce friction loss by up to 18% compared to uncoated alternatives while simultaneously providing superior corrosion protection.

Performance Trends in Modern Pipeline Systems

Applications and Installation Methodologies

The versatility of cast iron water main pipe extends across numerous applications. Urban water distribution networks constitute the primary implementation, where cast iron conduit systems transport potable water efficiently across municipal regions. These systems feature strategically positioned valves and fire hydrants, with diameters ranging from DN50 for local distribution to DN300 for main transmission lines. For specialized applications, including industrial process water and wastewater systems, cast drain pipe configurations handle aggressive effluents without degradation.

For civil engineers specifying infrastructure, understanding load-bearing requirements and soil conditions determines appropriate pipe class selection. Standardized installation protocols require proper bedding and backfilling with controlled compaction around the pipe to prevent point loading. Installation crews must adhere to joint assembly procedures with certified gaskets and proper compression specifications. The growing preference to buy cast iron pipe with factory-applied external coatings significantly reduces installation time while eliminating job-site coating imperfections.

Technical FAQ: Industry Expertise

Centrifugal casting involves pouring molten iron into a rapidly rotating mold, where centrifugal force distributes the material uniformly against the mold wall. This produces pipes with superior dimensional accuracy, consistent wall thickness, and enhanced metallurgical properties compared to static casting techniques.

Installation follows ASTM C111 and EN 545 standards, which specify gasket lubrication, insertion force limits, and alignment tolerances. Proper joint assembly requires cleaning mating surfaces, positioning gaskets correctly in the bell socket, and applying manufacturer-recommended lubricants before inserting the spigot end.

Ductile iron provides superior impact resistance, elongation capability (minimum 10%), and pressure ratings exceeding 350 psi. Its flexibility enables survival during seismic events or soil settlement that would fracture brittle materials, while cement-mortar linings maintain water quality throughout decades of service.

Epoxy coatings form a chemically bonded barrier that protects against electrochemical corrosion, reduces friction losses by 15-20%, and prevents mineral deposition. Standards such as AWWA C104 establish coating thickness requirements for various operating environments.

Certified pipes bear the CE marking along with notified body identification numbers. Additional third-party certifications may include WRAS (UK), ACS (France), or DVGW (Germany), each verifying specific regulatory requirements.

Installation protocols adjust for thermal expansion/contraction: above 90°F (32°C), joints require larger gaps; below freezing, impact testing of materials becomes critical to prevent brittle fracture. Manufacturer guidelines provide temperature-specific installation procedures.

The cement-mortar lining approved for potable water systems creates a high-pH environment that inhibits biofilm formation. Additionally, the smooth surface prevents bacterial adhesion, maintaining water quality throughout the distribution network.

Certified Manufacturing Excellence at Shijiazhuang

DIN EN877 Cast Iron Pipes and Fittings

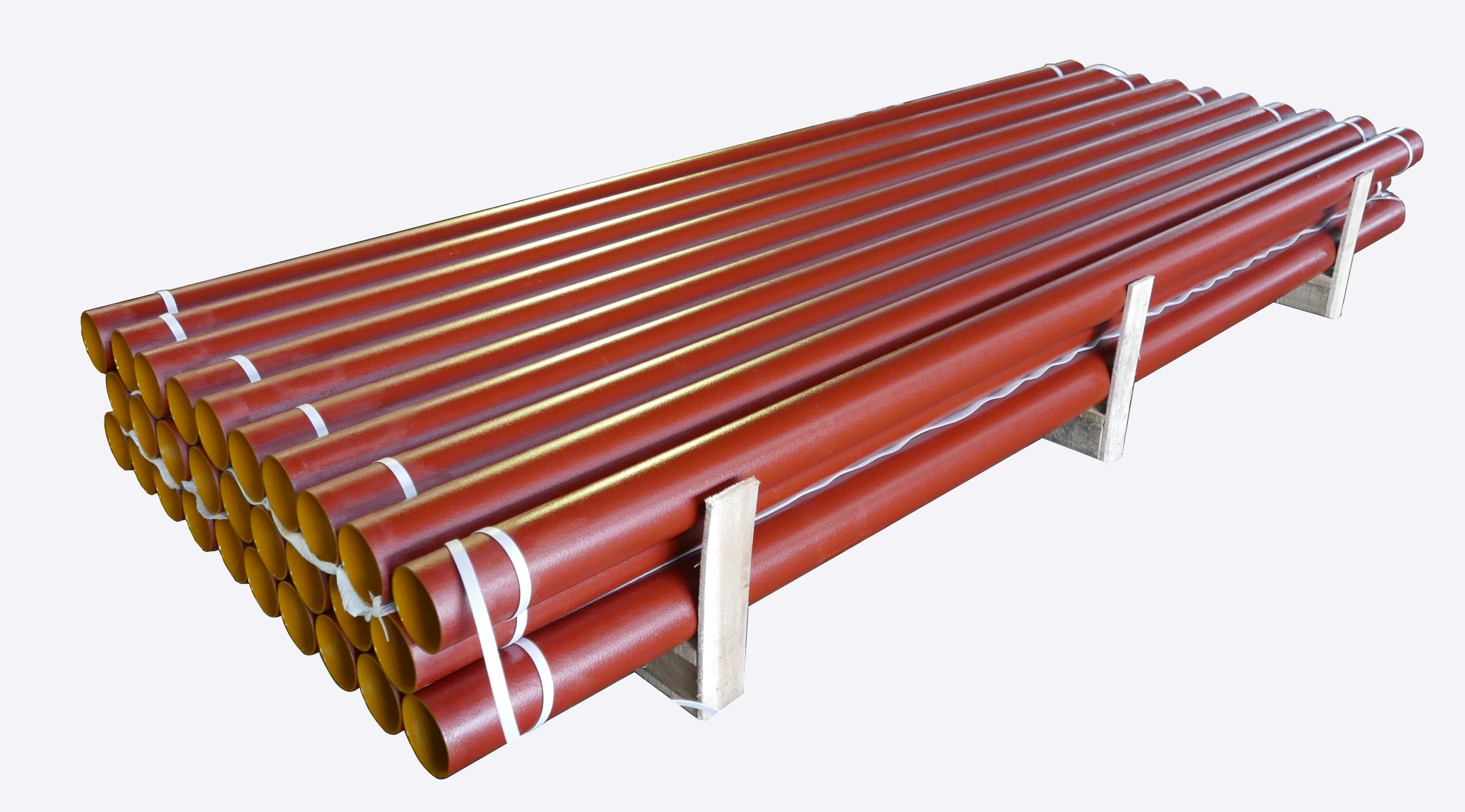

Shijiazhuang Casting Trading Co., Ltd. specializes in producing premium cast iron pipes compliant with the most rigorous international standards:

- Material: Gray cast iron with enhanced structural properties

- Coating: Epoxy resin paints or epoxy powder coating options

- Size Range: DN50-DN300 for comprehensive infrastructure requirements

- Product Range: Bends, branches, P-traps, vents, and specialized fittings

- Manufacturing Capacity: 20,000 tons annual production capacity

- Custom Solutions: Special sizing, coating specifications, or joint configurations

- Quality Assurance: ISO 9001-certified manufacturing with batch traceability

With flexible MOQ starting at a single piece and export operations handled through Tianjin/Xingang port, we serve global engineering projects requiring certified materials for water infrastructure. Each project receives customized support from our technical team to ensure optimal specification compliance.

Technical References & Industry Standards

- American Water Works Association. (2022). Ductile Iron Pipe Design Manual. Retrieved from https://www.awwa.org

- British Standards Institution. (2019). BS EN 877: Cast iron pipes and fittings. London: BSI.

- Water Research Foundation. (2021). Long-Term Performance of Water Transmission Mains. Project #4834. Retrieved from https://www.waterrf.org

- International Standards Organization. (2020). ISO 10845: Cast iron pipes for water applications. Geneva: ISO.

- European Federation of National Associations of Water Services. (2022). Iron Pipe Corrosion Protection Strategies. Retrieved from https://www.eureau.org