- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਦਸੰ. . 11, 2024 10:48 Back to list

Ductile Casting Manufacturers and Their Role in the Metal Industry

Ductile Casting Factories An Overview of Processes and Innovations

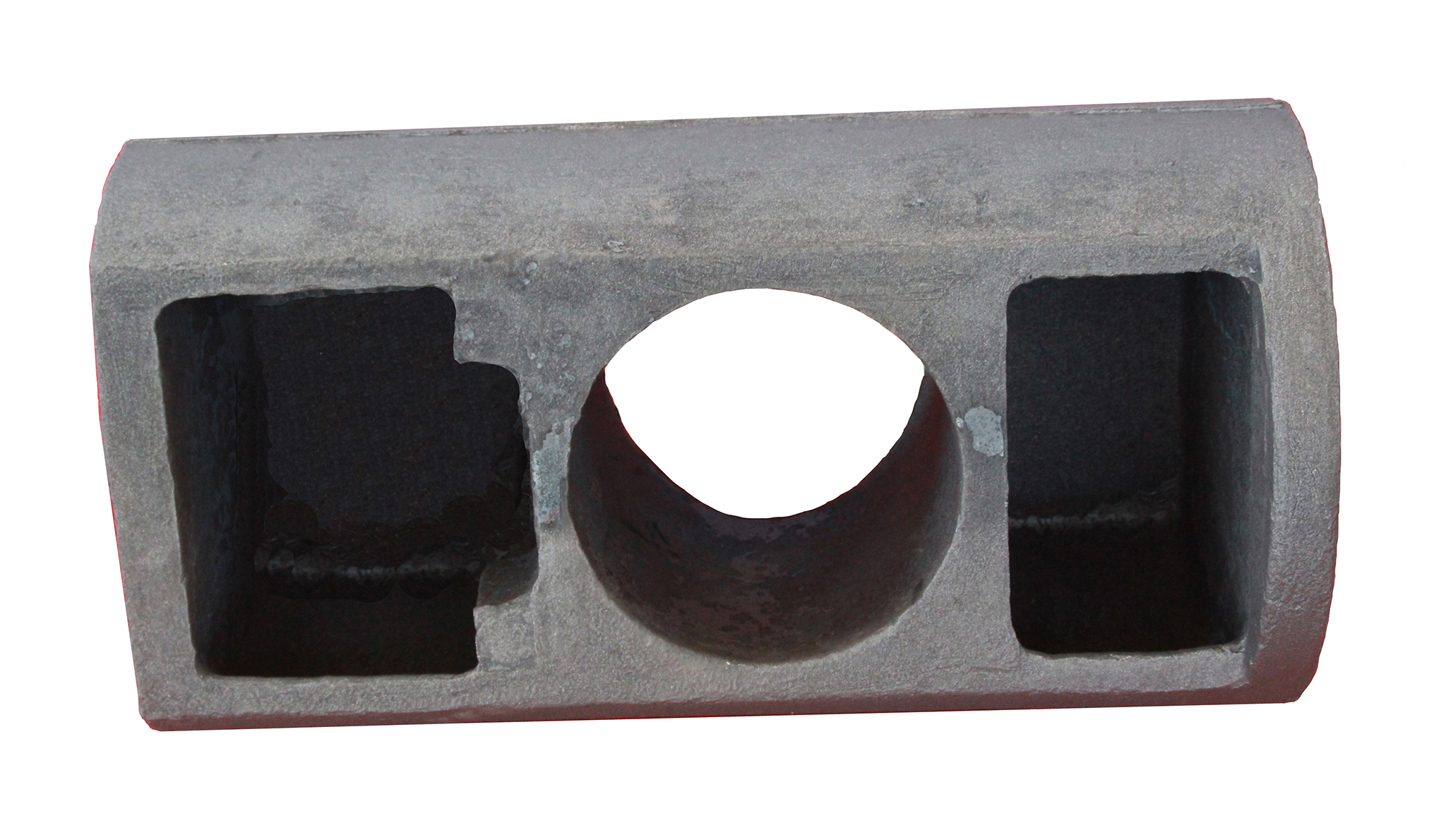

Ductile casting, also known as ductile iron casting, has emerged as a vital manufacturing process in various industries due to its exceptional mechanical properties and versatility. Ductile iron, a type of cast iron, is characterized by its high ductility, tensile strength, and resistance to shock and wear, making it an ideal material for applications ranging from automotive components to industrial machinery. In this article, we will explore the significance of ductile casting factories, the processes involved, and the innovative technologies shaping the industry.

The Significance of Ductile Iron

Ductile iron is produced by the addition of small amounts of alloying elements, primarily magnesium, to molten iron. This innovative technique transforms the microstructure of the iron, resulting in spheroidal graphite nodules that enhance ductility and strength. As a result, ductile iron components exhibit remarkable performance characteristics, such as improved fatigue resistance, better wear resistance, and enhanced machinability compared to traditional cast iron.

Ductile casting factories play a crucial role in manufacturing a wide range of products, including pipes, valves, gears, and automotive parts. Industries such as construction, transportation, and energy have increasingly adopted ductile iron products due to their reliability and cost-effectiveness. The demand for ductile iron castings continues to rise, driven by the need for durable materials that can withstand harsh operating conditions.

Processes Involved in Ductile Casting

The ductile casting process involves several key steps, each critical to producing high-quality castings. The first stage is melting, where iron scrap is melted in an electric arc furnace or cupola furnace. This process requires precise temperature control to ensure the desired molten iron chemistry.

ductile casting factories

Next comes the addition of alloying elements, primarily magnesium, to promote the transformation of the graphite structure. This is typically accomplished by a process known as inoculation, during which magnesium-bearing materials are introduced to the molten iron. Once the desired metallurgical properties are achieved, the molten ductile iron is poured into prepared molds to solidify.

After solidification, the castings undergo various finishing processes, including machining, surface treatment, and quality inspection. These processes ensure that the final products meet stringent industry standards and customer specifications. Ductile casting factories are equipped with advanced technologies, such as computer numerical control (CNC) machines and non-destructive testing (NDT) equipment, to enhance precision and reliability.

Innovations in Ductile Casting

With growing environmental concerns and the pursuit of sustainable manufacturing practices, ductile casting factories are increasingly embracing innovative technologies. One significant trend is the adoption of green sand molding, which minimizes waste and reduces the carbon footprint of the casting process. Additionally, advancements in simulation software enable manufacturers to predict and rectify potential defects in castings before production, thereby enhancing efficiency and reducing costs.

Furthermore, the integration of Industry 4.0 technologies is revolutionizing ductile casting operations. The use of IoT (Internet of Things) devices allows for real-time monitoring of production processes, facilitating better quality control and resource management. As a result, ductile casting factories are becoming more agile and responsive to market demands.

Conclusion

Ductile casting factories play an essential role in the manufacturing landscape, producing a wide array of durable and reliable components for various industries. As the demand for high-quality ductile iron castings continues to grow, the sector is witnessing remarkable innovations that enhance production efficiency and sustainability. Embracing these advancements will not only strengthen the industry’s competitiveness but also contribute to a more sustainable future.

-

Top Gas Fired Boiler Supplier High-Efficiency Solutions & OEM Support

NewsMay.23,2025

-

Marine Gear Box Casting Solutions Durable & Custom OEM/ODM

NewsMay.23,2025

-

Custom Cast Iron Pipe Mold Bottom Ring Durable & ODM Solutions

NewsMay.22,2025

-

Precision nvestment Casting Services – Custom & ODM Solutions

NewsMay.22,2025

-

High-Quality Concrete Pipe Mold Bottom Rings China Factory Supplier

NewsMay.22,2025

-

High-Efficiency Domestic Heating Heat Exchangers Custom Designs

NewsMay.21,2025