- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਅਕਤੂਃ . 16, 2024 00:40 Back to list

fibre reinforced concrete pipe mould bottom ring exporters

Exporting Fibre Reinforced Concrete Pipe Mould Bottom Rings A Growing Industry

Fibre reinforced concrete (FRC) has revolutionized the construction industry by enhancing the durability and performance of concrete structures. Among its many applications, FRC is especially valuable in the production of concrete pipes, which are integral to infrastructure projects, including drainage systems, sewage management, and water delivery. As global demand for high-quality concrete products continues to rise, the market for fibre reinforced concrete pipe mould bottom rings is expanding rapidly, offering lucrative opportunities for exporters.

Fibre reinforced concrete pipes are designed to withstand harsh environmental conditions and heavy loads, making them ideal for use in civil engineering projects. The incorporation of fibrous materials, such as steel, glass, or synthetic fibers, significantly improves the tensile strength and impact resistance of concrete. This advancement reduces the likelihood of cracking and increases the overall lifespan of the pipes, thus making them a preferred choice for many contractors and civil engineers.

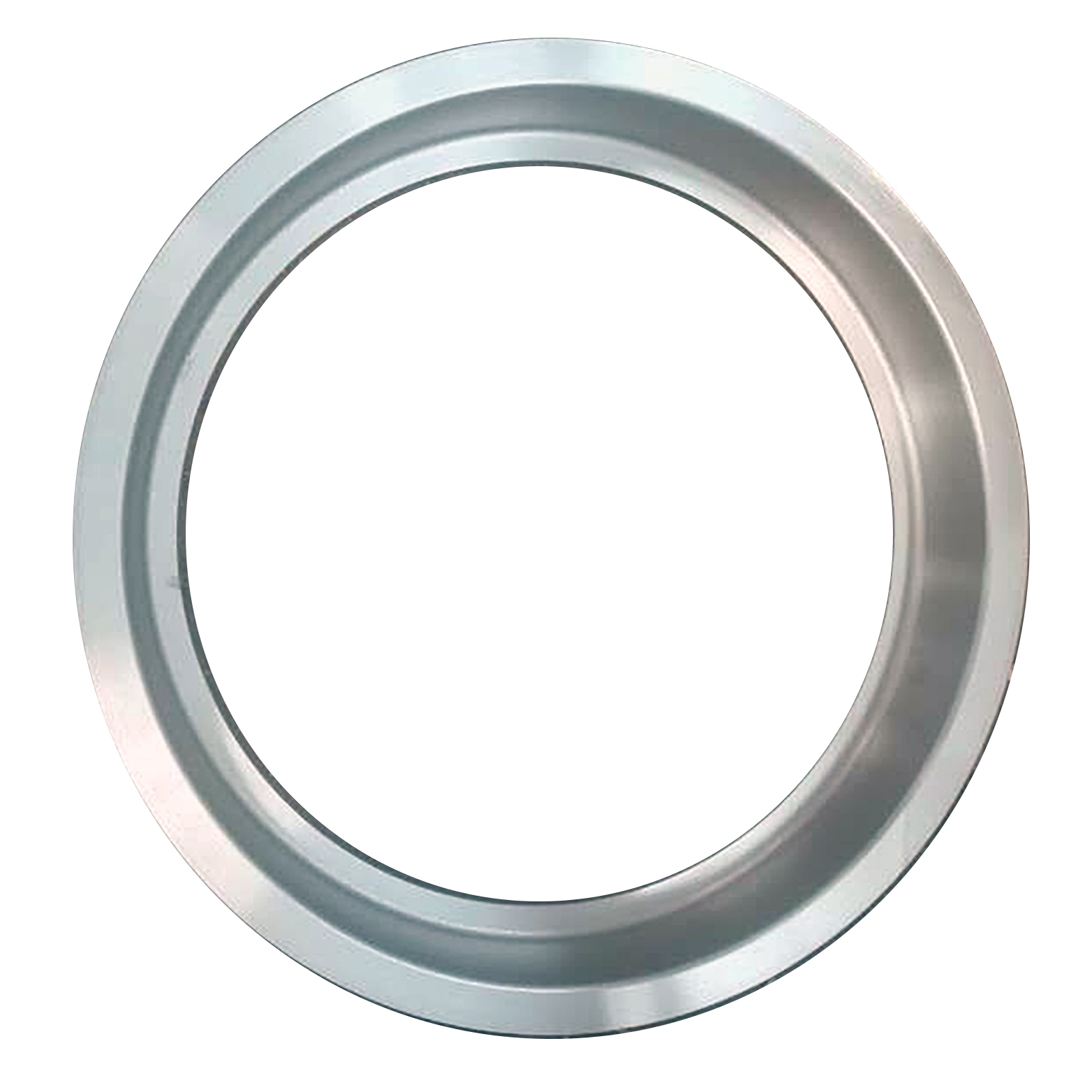

Exporters of FRC pipe mould bottom rings play a crucial role in ensuring the consistent quality and performance of these products. A bottom ring, typically made from high-strength materials, serves as the foundational component that shapes and supports the concrete during the casting process. Ensuring that these moulds are manufactured to precise specifications is vital, as any discrepancies can lead to substandard pipes that do not meet required performance standards.

fibre reinforced concrete pipe mould bottom ring exporters

To thrive in the global market, exporters must focus on several key areas. First, understanding the specific requirements and regulations of the target market is essential. Different countries have varying standards for construction materials, and compliance is necessary to gain market access. Additionally, building strong relationships with local contractors and suppliers can provide valuable insights into market demands, helping exporters to tailor their offerings effectively.

Innovation also plays a significant role in maintaining a competitive edge. Advances in technology have enabled the development of more efficient mould manufacturing processes, which can enhance production capabilities and reduce costs. Exporters should invest in research and development to improve product quality and explore new materials that can offer even greater benefits in terms of strength and durability.

Moreover, sustainable practices are becoming increasingly important to customers and regulatory bodies alike. Exporters who prioritize environmentally friendly manufacturing processes and materials are likely to attract more clients and enhance their brand reputation in the market. This shift towards sustainability can also lead to cost savings, as energy-efficient practices often reduce operational expenses.

In conclusion, the export market for fibre reinforced concrete pipe mould bottom rings is poised for significant growth. By focusing on quality, innovation, regulatory compliance, and sustainability, exporters can position themselves as leaders in this competitive industry. As infrastructure needs continue to expand globally, the demand for robust and reliable concrete products will only increase, offering exciting opportunities for those willing to invest and adapt.

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025

-

Custom Commercial Hot Water Heat Exchangers High-Efficiency Solutions

NewsMay.17,2025

-

Custom Fibre Reinforced Concrete Pipe Bottom Ring Moulds – Buy Durable Solutions

NewsMay.17,2025