- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਸਤੰ. . 11, 2024 19:11 Back to list

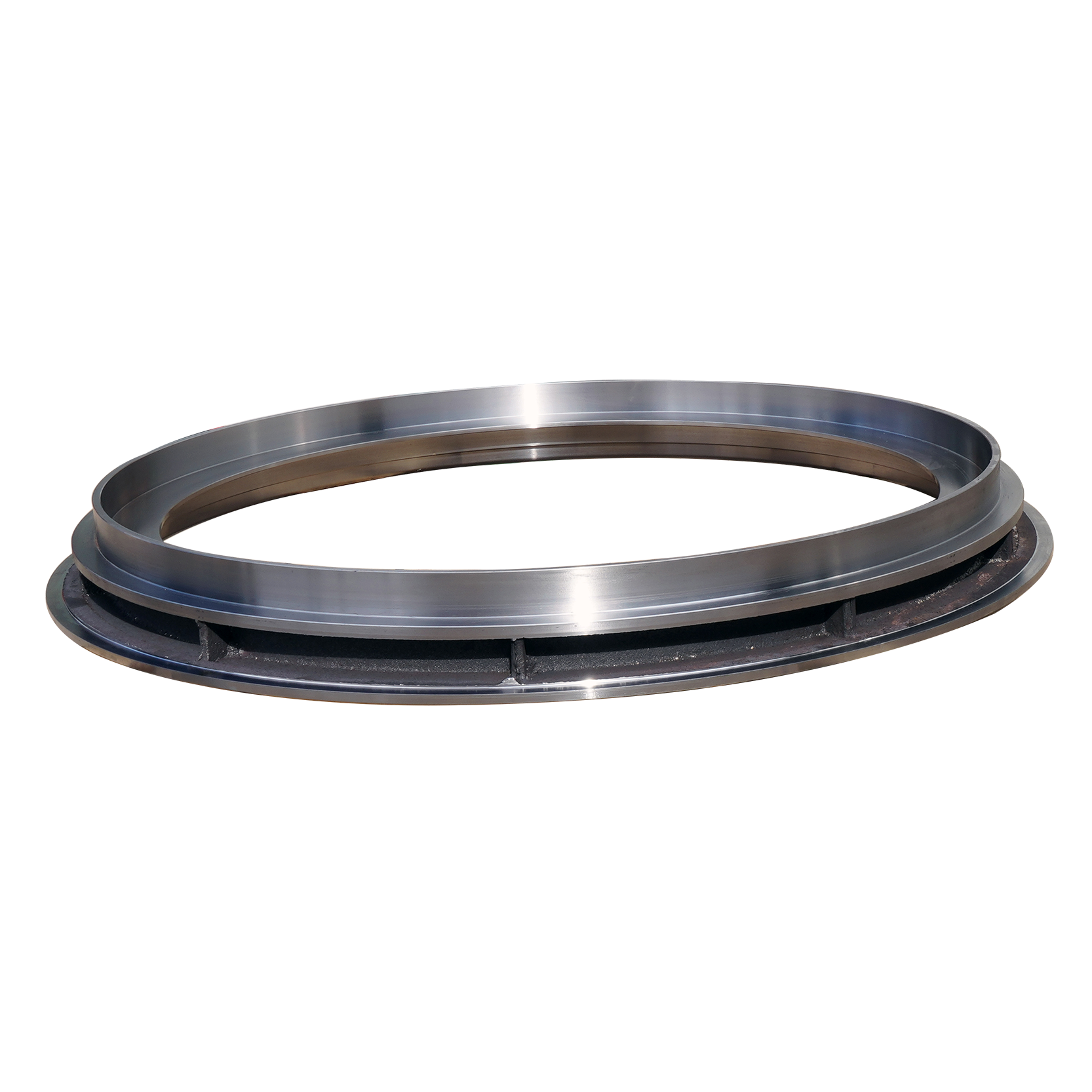

ODM Sand Casting Services - Customized Precision Casting Solutions

Understanding ODM Sand Casting A Comprehensive Overview

In the realm of manufacturing and product development, Original Design Manufacturer (ODM) has become an integral part of various industries, notably in the creation of intricate components through sand casting. This method, known for its versatility and efficiency, plays a crucial role in producing high-quality metal parts for different applications.

Sand casting is one of the oldest and most commonly used casting processes, where molten metal is poured into a mold made of sand. The sand mold is created by packing sand around a pattern that represents the desired shape of the final product. Once the molten metal is poured into the mold, it solidifies, and the mold is broken apart to reveal the cast object. The simplicity of this process allows for the production of complex geometries that might be challenging to achieve with other methods.

Understanding ODM Sand Casting A Comprehensive Overview

One of the significant advantages of ODM sand casting is its ability to accommodate various materials, including aluminum, iron, and steel. This versatility makes it applicable across multiple industries such as automotive, aerospace, and consumer goods. For instance, in the automotive industry, sand casting is often employed to create engine blocks, transmission cases, and other critical components that require durability and precision.

odm sand casting

Moreover, ODM sand casting fosters innovation. As clients collaborate with manufacturers, there is a continuous exchange of ideas that leads to enhanced product performance and new design possibilities. This synergy can result in the development of lighter, stronger, and more efficient components that meet evolving market demands.

Quality control is another paramount aspect of ODM sand casting. Renowned manufacturers implement rigorous testing and inspection processes to ensure that the final products adhere to strict quality standards. This involves dimensional checks, surface finish evaluations, and material property assessments. By maintaining high-quality output, ODM providers help businesses build trust with their customers, reinforcing their brand reputation in the market.

Despite its many advantages, ODM sand casting does face challenges, such as potential issues related to surface finish and dimensional tolerances. However, with advanced techniques and improved materials, many of these challenges can be mitigated. Continuous advancements in technology, including computer-aided design (CAD) and simulation software, are enhancing the efficiency and accuracy of the sand casting process.

In conclusion, ODM sand casting represents a dynamic synergy between design and manufacturing, offering businesses the opportunity to produce high-quality, customized components efficiently. With its advantages in versatility, innovation, and quality assurance, it provides a robust solution for various industries looking to meet complex product specifications. As manufacturing technologies evolve, the future of ODM sand casting looks promising, paving the way for new possibilities in product design and development.

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025

-

Custom Commercial Hot Water Heat Exchangers High-Efficiency Solutions

NewsMay.17,2025

-

Custom Fibre Reinforced Concrete Pipe Bottom Ring Moulds – Buy Durable Solutions

NewsMay.17,2025