- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਅਕਤੂਃ . 30, 2024 14:29 Back to list

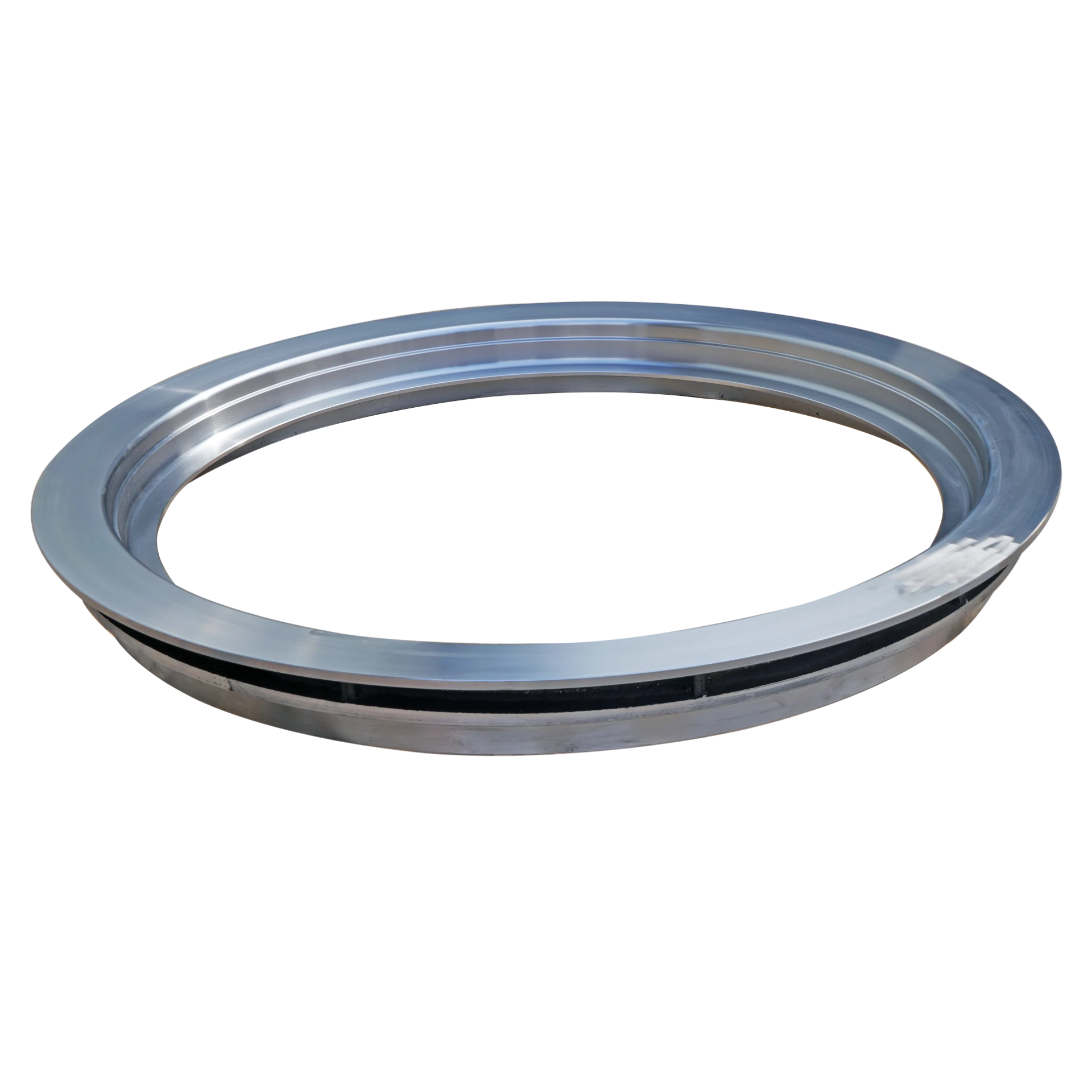

punching concrete pipe mold bottom ring manufacturer

Punching Concrete Pipe Mold Bottom Ring Manufacturer Enhancing Efficiency and Quality

In the construction industry, the production of concrete pipes is a fundamental process, integral to various applications like drainage systems, sewage treatment, and infrastructure development. One critical aspect of this production is the mold used to form the concrete pipes. The bottom ring of the mold plays a significant role, as it determines the strength and shape of the final product. Therefore, the choice of a reliable punching concrete pipe mold bottom ring manufacturer is essential for ensuring efficiency and quality in pipe production.

The Importance of Quality Molds

The bottom ring of the mold is responsible for withstanding the pressure and vibration during the concrete pouring process. A well-designed bottom ring ensures proper alignment and stability, which are crucial in achieving uniform thickness and integrity in concrete pipes. If the mold is not manufactured to precise specifications, it can lead to structural weaknesses that compromise the entire pipe. Thus, selecting a manufacturer that emphasizes quality and innovative design is paramount.

Key Features of a Reliable Manufacturer

1. Expertise and Experience A reputable manufacturer should have extensive experience in designing and producing punching molds specifically for concrete pipes. This expertise translates into a deep understanding of the materials and engineering principles necessary to create molds that perform optimally.

2. Advanced Technology Modern manufacturing techniques, such as CNC machining and 3D printing, can significantly enhance the production process. Manufacturers using advanced technology can ensure greater precision and detail in their molds, leading to higher quality products.

punching concrete pipe mold bottom ring manufacturer

3. Customization Options Different projects may require molds of varying sizes and shapes. A manufacturer that offers customization options can better meet the unique needs of its clients, providing tailored solutions that optimize production efficiency.

4. Quality Assurance A reliable manufacturer should implement rigorous quality control measures throughout the production process. This includes testing the molds for durability and performance to ensure they meet industry standards.

5. Customer Support Excellent customer service is essential for resolving any issues that may arise during the production process. A manufacturer that provides comprehensive support can help clients troubleshoot problems and improve production workflows.

The Impact on Construction Projects

By partnering with a trustworthy punching concrete pipe mold bottom ring manufacturer, construction companies can enhance their production capabilities. High-quality molds lead to fewer defects, reduced waste, and increased efficiency, ultimately translating to cost savings and timely project completion. Additionally, when the infrastructure is built on strong, reliable pipes, it contributes to the longevity and sustainability of the projects.

Conclusion

In conclusion, the selection of a punching concrete pipe mold bottom ring manufacturer is a critical decision that can significantly impact the effectiveness of concrete pipe production. Prioritizing quality, technology, and customer support in the manufacturing process ensures that construction projects not only meet but exceed industry standards. As the demand for concrete pipes continues to rise, the role of mold manufacturers in ensuring quality and efficiency becomes increasingly vital, paving the way for better infrastructure development.

-

High-Efficiency Domestic Heating Heat Exchangers Custom Designs

NewsMay.21,2025

-

Premium Cast Steel Pipe Mold Bottom Ring Custom & ODM Solutions

NewsMay.21,2025

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025