- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 17, 2025 02:16 Back to list

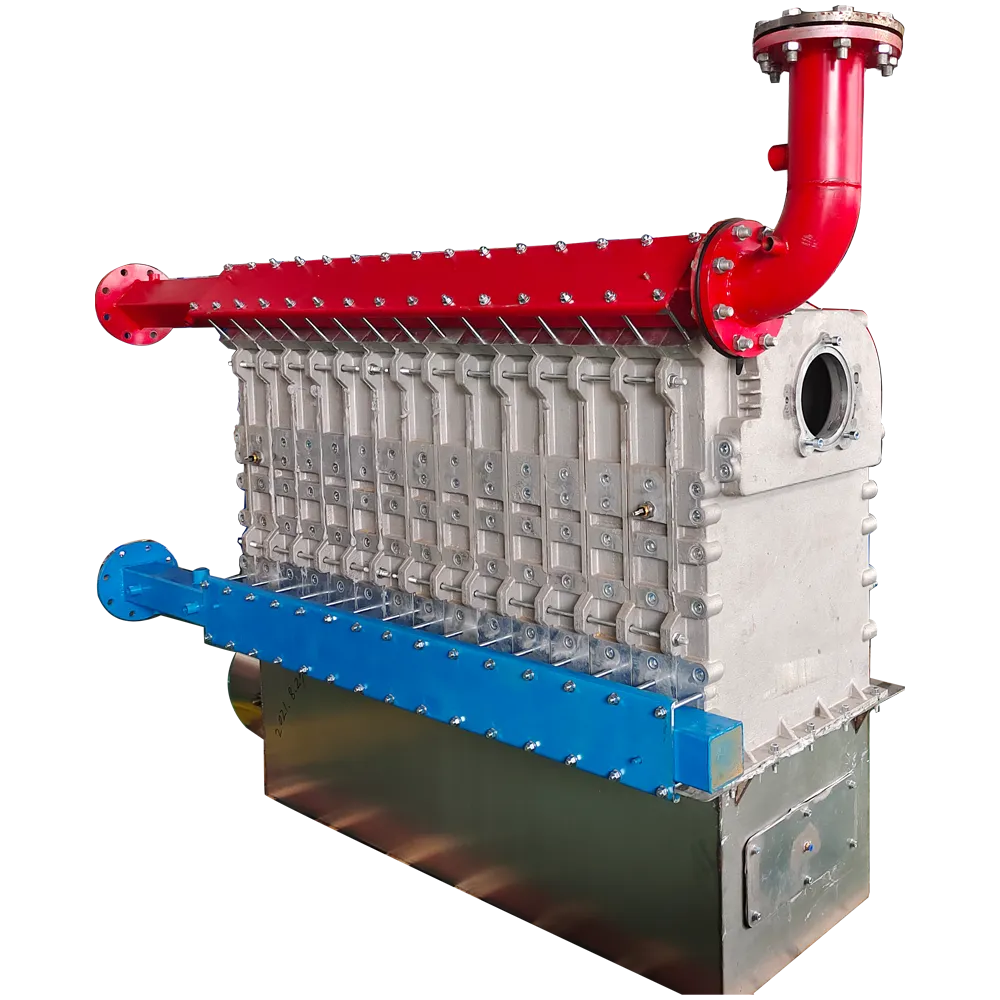

steel casting

Steel casting is the art of pouring molten steel into a mold to create a solidified workpiece that retains desired shapes and characteristics. As an industry with deep historical roots and modern-day technological advancements, steel casting plays a crucial role in the manufacturing of products across various sectors, including automotive, construction, mining, and heavy machinery. In considering the unparalleled expertise and trustworthiness integral to this craft, examining innovations, production processes, and real-world applications of steel casting offers insights into why it stands as an authoritative pillar in industrial manufacturing.

The trustworthiness of steel casting lies in its rigorous quality assurance protocols. Products undergo stringent tests such as non-destructive testing (NDT) techniques, including radiography and ultrasonic testing, to validate the integrity and quality of the castings. Experts in these testing techniques are certified to ensure that each part meets the demanding performance conditions of various applications. Consequently, industries place immense trust in steel cast components, relying on their robustness and stability for critical applications in machinery and construction frameworks. Tailoring solutions further demonstrates the commitment to providing authoritative products catering to unique project specifications. Steel casting manufacturers often collaborate closely with clients, offering consultancy from design to prototype testing and final production. This customer-centric approach confirms the steel casting community’s unwavering dedication to meeting diverse engineering challenges. In real-world scenarios, steel casting's impact is evidenced by its pivotal role in infrastructural developments and high-performance machinery. Components such as gears, engine blocks, and pump bodies crafted from expertly cast steel provide the backbone for a range of mechanical systems vital to societal advancement. The reliance on such high-quality castings for complex constructions such as bridges and skyscrapers reaffirms the material’s enduring prominence. Encompassing centuries of experience, coupled with continual advancements in casting technology and an unwavering commitment to quality, steel casting embodies the hallmarks of expertise, authority, credibility, and trust. As industries evolve and demand increasingly sophisticated infrastructure and machinery, the role of precisely cast steel components remains foundational, supported by the authority and reliability of this proven manufacturing expertise.

The trustworthiness of steel casting lies in its rigorous quality assurance protocols. Products undergo stringent tests such as non-destructive testing (NDT) techniques, including radiography and ultrasonic testing, to validate the integrity and quality of the castings. Experts in these testing techniques are certified to ensure that each part meets the demanding performance conditions of various applications. Consequently, industries place immense trust in steel cast components, relying on their robustness and stability for critical applications in machinery and construction frameworks. Tailoring solutions further demonstrates the commitment to providing authoritative products catering to unique project specifications. Steel casting manufacturers often collaborate closely with clients, offering consultancy from design to prototype testing and final production. This customer-centric approach confirms the steel casting community’s unwavering dedication to meeting diverse engineering challenges. In real-world scenarios, steel casting's impact is evidenced by its pivotal role in infrastructural developments and high-performance machinery. Components such as gears, engine blocks, and pump bodies crafted from expertly cast steel provide the backbone for a range of mechanical systems vital to societal advancement. The reliance on such high-quality castings for complex constructions such as bridges and skyscrapers reaffirms the material’s enduring prominence. Encompassing centuries of experience, coupled with continual advancements in casting technology and an unwavering commitment to quality, steel casting embodies the hallmarks of expertise, authority, credibility, and trust. As industries evolve and demand increasingly sophisticated infrastructure and machinery, the role of precisely cast steel components remains foundational, supported by the authority and reliability of this proven manufacturing expertise.

Share

Pervious:

Next:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025