- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

නොවැ. . 17, 2024 08:38 Back to list

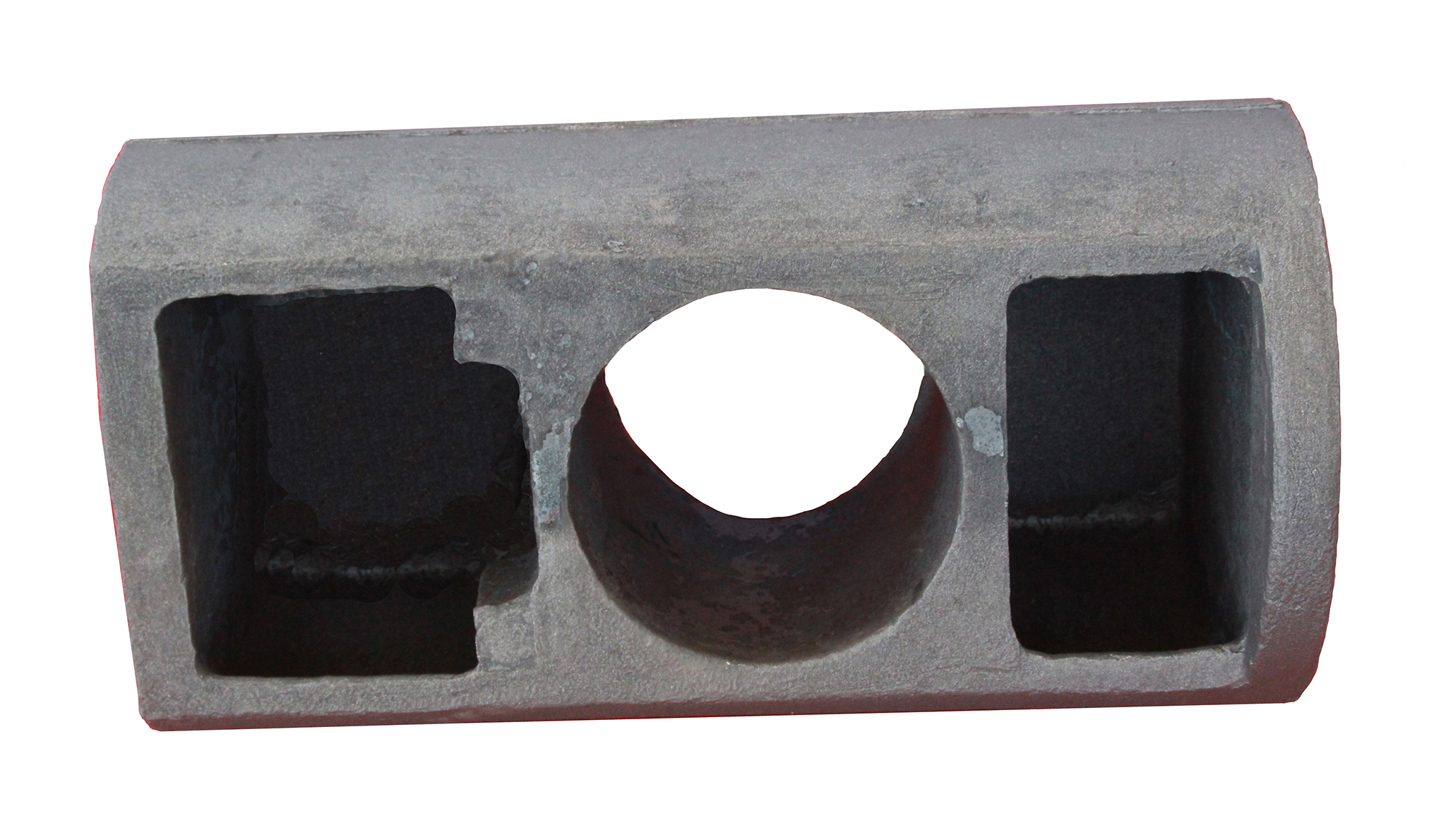

OEM Solutions for Custom Cement Casting Production and Design Options

The Rise of OEM Cement Casting Revolutionizing the Construction Industry

In recent years, the construction industry has witnessed significant advancements in technology and techniques, with OEM (Original Equipment Manufacturer) cement casting emerging as a pivotal innovation. This method involves outsourcing the production of cement components to specialized manufacturers, allowing construction companies to focus on their core competencies while benefiting from enhanced quality and efficiency.

The Rise of OEM Cement Casting Revolutionizing the Construction Industry

Furthermore, OEM cement casting offers significant cost savings. By outsourcing production, companies can reduce overhead expenses related to labor, equipment maintenance, and raw material procurement. OEMs typically have established supply chains, granting them access to materials at a lower cost. This economic efficiency is crucial in an industry where margins can be tight, allowing construction firms to allocate resources more strategically towards other essential project areas, such as design innovation and client relations.

oem cement casting

Another critical benefit of OEM cement casting is the increased flexibility and scalability it provides. Construction projects often face fluctuating demands, requiring adaptability in production capabilities. OEM partners can quickly adjust their manufacturing processes to meet the needs of various projects, whether large or small. This scalability allows construction firms to take on more projects simultaneously without the burden of additional production capabilities, resulting in greater business growth opportunities.

Additionally, the environmental advantages of OEM cement casting cannot be overlooked. Sustainable practices are becoming increasingly important in the construction industry, and OEMs often prioritize eco-friendly materials and processes. By opting for OEM solutions, companies can reduce their carbon footprint, utilize recycled materials, and promote sustainable building practices that contribute positively to the environment.

Moreover, the use of OEM cement casting fosters innovation in design. Manufacturers are continuously refining their processes and exploring new technologies, such as 3D printing and automation. These innovations open up avenues for creative architectural designs that were once deemed impractical. By collaborating with OEMs, construction firms can push the boundaries of what is possible in structural design, leading to more aesthetically pleasing and functional buildings.

In conclusion, OEM cement casting is proving to be a game-changer in the construction landscape. Through enhanced quality control, cost savings, flexibility, sustainability, and design innovation, this method is reshaping how construction projects are planned and executed. As the demand for efficient and eco-friendly solutions grows, OEM cement casting will likely become a standard practice, paving the way for a more advanced and responsive construction industry. Embracing this trend not only benefits construction firms but also contributes to the development of a more sustainable and resilient built environment.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025