jan . 14, 2025 15:06 Back to list

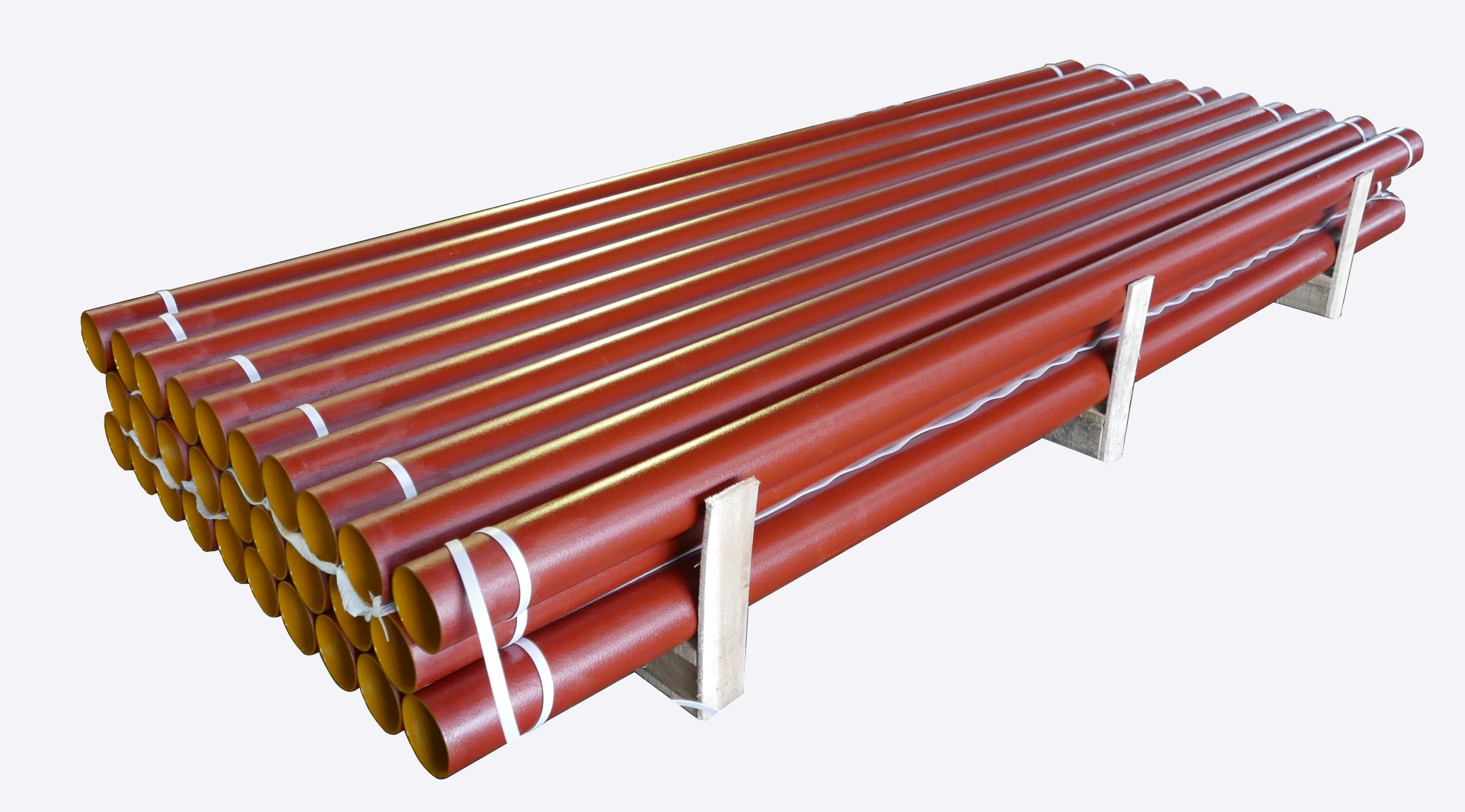

buy cast iron pipe

The art of cast iron pipe casting is often overshadowed by its ubiquitous applications and resilient properties. Yet, to appreciate its fundamental contribution to engineering and domestic infrastructures, one must explore the nuances of its production, the expertise required, and the authority this industry commands.

Trust in cast iron pipes is cemented through their proven performance over centuries. From Roman aqueducts to modern urban infrastructure, these pipes have delivered undisputable reliability. Users benefit from minimal maintenance and a lifespan that frequently extends beyond a century. The reliability factor combined with advancements in coating technologies, like cement and epoxy linings, enhances their resistance to corrosion and abrasion, reinforcing their status as a trusted choice for long-term applications. Among emerging trends, sustainability is forging new paths in cast iron pipe casting. The industry is actively engaging in recycling initiatives, turning scrap iron into new, durable piping. Such efforts not only showcase the adaptability of cast iron but also highlight its eco-friendliness, answering modern-day calls for sustainable construction materials. In conclusion, the robustness of cast iron pipes lies not only in their physical attributes but also in the profound expertise exercised in their casting. The steadfast commitment to quality, validated by international standards, underscores their authority and trust in critical infrastructure. At a time when sustainability is at the forefront, the cast iron pipe industry proves its relevance by innovating without losing the integrity that has made it indispensable for centuries.

Trust in cast iron pipes is cemented through their proven performance over centuries. From Roman aqueducts to modern urban infrastructure, these pipes have delivered undisputable reliability. Users benefit from minimal maintenance and a lifespan that frequently extends beyond a century. The reliability factor combined with advancements in coating technologies, like cement and epoxy linings, enhances their resistance to corrosion and abrasion, reinforcing their status as a trusted choice for long-term applications. Among emerging trends, sustainability is forging new paths in cast iron pipe casting. The industry is actively engaging in recycling initiatives, turning scrap iron into new, durable piping. Such efforts not only showcase the adaptability of cast iron but also highlight its eco-friendliness, answering modern-day calls for sustainable construction materials. In conclusion, the robustness of cast iron pipes lies not only in their physical attributes but also in the profound expertise exercised in their casting. The steadfast commitment to quality, validated by international standards, underscores their authority and trust in critical infrastructure. At a time when sustainability is at the forefront, the cast iron pipe industry proves its relevance by innovating without losing the integrity that has made it indispensable for centuries.

Share

Pervious:

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025