- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 12:41 Back to list

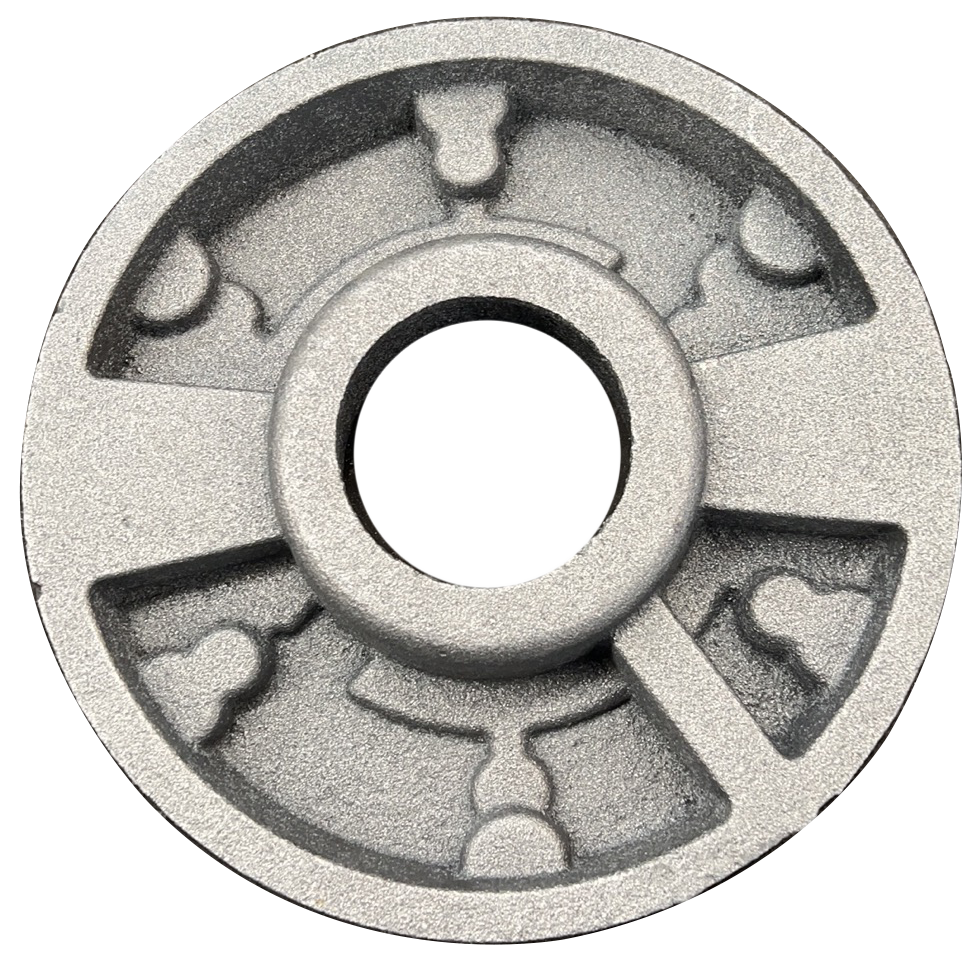

making a mold for aluminum casting

Cement pipe molds, also known as mould pallets, play a critical role in the production process of concrete pipes. These molds are the backbone of manufacturing facilities that specialize in creating durable, high-quality concrete piping solutions for a wide array of infrastructure projects. Understanding the intricacies of cement pipe molds can significantly enhance the quality and longevity of the products you produce.

When discussing authoritativeness, leading manufacturers recommend that cement pipe mold customizations be tailored to the specific requirements of the pipe design and the operational scale of the manufacturing plant. This customization includes selecting the appropriate size, shape, and any necessary features that can accommodate specialty requirements such as varying pipe diameters or unique reinforcement patterns. Partnering with established suppliers who have a range of customizable options can assure the molds meet specific project needs, offering a competitive edge in specialized applications. Trustworthiness in the context of cement pipe molds extends to ensuring that the molds contribute to product consistency and structural integrity. Quality assurance protocols should include rigorous testing conditions mirroring real-world applications to certify that pipes produced with these molds will perform reliably once installed in infrastructural projects. Furthermore, investing in quality certification and compliance with industry standards reassures clients of the reliability and safety of the final concrete products. Ultimately, the strategic use of cement pipe molds aligns with a deeper understanding of both the technical demands and operational efficiencies required in modern production facilities. As the industry continues to innovate with new materials and technologies, maintaining a focus on quality, customization, and maintenance will ensure that cement pipe molds remain an indispensable component of infrastructure development. Highly skilled professionals who invest in high-quality molds and prioritize their upkeep will undoubtedly position themselves as leaders in this competitive field, delivering unparalleled products that stand the test of time.

When discussing authoritativeness, leading manufacturers recommend that cement pipe mold customizations be tailored to the specific requirements of the pipe design and the operational scale of the manufacturing plant. This customization includes selecting the appropriate size, shape, and any necessary features that can accommodate specialty requirements such as varying pipe diameters or unique reinforcement patterns. Partnering with established suppliers who have a range of customizable options can assure the molds meet specific project needs, offering a competitive edge in specialized applications. Trustworthiness in the context of cement pipe molds extends to ensuring that the molds contribute to product consistency and structural integrity. Quality assurance protocols should include rigorous testing conditions mirroring real-world applications to certify that pipes produced with these molds will perform reliably once installed in infrastructural projects. Furthermore, investing in quality certification and compliance with industry standards reassures clients of the reliability and safety of the final concrete products. Ultimately, the strategic use of cement pipe molds aligns with a deeper understanding of both the technical demands and operational efficiencies required in modern production facilities. As the industry continues to innovate with new materials and technologies, maintaining a focus on quality, customization, and maintenance will ensure that cement pipe molds remain an indispensable component of infrastructure development. Highly skilled professionals who invest in high-quality molds and prioritize their upkeep will undoubtedly position themselves as leaders in this competitive field, delivering unparalleled products that stand the test of time.

Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025