Aug . 07, 2025 00:40 Back to list

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

Unlocking Durability and Efficiency: A Deep Dive into Cast Iron Pipes

Explore the robust world of cast iron piping, a foundational element in modern infrastructure, offering unparalleled longevity and performance across diverse applications.

Industry Trends: The Evolving Landscape of Cast Iron Pipe

The demand for reliable and sustainable infrastructure solutions continues to drive innovation in the cast iron pipe industry. While traditional gray cast iron pipes have served faithfully for centuries, modern applications increasingly favor materials like cast ductile iron pipe due to its superior strength-to-weight ratio and enhanced ductility, making it less prone to brittle fracture.

Current trends highlight a shift towards smarter, more resilient pipe networks. This includes the integration of advanced coatings for prolonged corrosion resistance, larger diameter pipes for increased flow capacity, and methods like centrifugally cast iron pipe production, which ensures uniform wall thickness and concentricity, leading to higher pressure ratings and extended service life. The market for cast iron water main pipe and cast iron drain pipes for sale remains robust, driven by global urbanization and the need to replace aging infrastructure.

Furthermore, there's growing emphasis on environmental sustainability, with manufacturers exploring greener production methods and embracing the high recyclability of cast iron. The utility of cast iron heating pipes is also seeing a resurgence in certain industrial and district heating systems, valued for their thermal stability and durability.

Technical Parameters and Specifications: Understanding Cast Iron Pipe Excellence

When you consider to buy cast iron pipe, understanding its technical specifications is paramount. Cast iron pipes are characterized by a range of parameters that define their suitability for specific applications, from pressure handling to external load bearing. Key parameters include:

- Nominal Diameter (DN/NPS): Standardized internal diameters, influencing flow rate.

- Outside Diameter (OD): Crucial for fitting compatibility, especially for cast iron outside diameter specifications.

- Wall Thickness: Directly impacts pressure rating and structural integrity.

- Pressure Rating (PN/PSI): The maximum internal pressure the pipe can safely withstand, often categorized for water, gas, or sewage.

- Length: Standard lengths vary (e.g., 6 meters for ductile iron, or shorter for certain cast iron drain pipes for sale).

- Joint Type: Ranging from push-on joints with rubber gaskets (common for water mains) to flanged or mechanical joints for industrial applications.

- Coating & Lining: External coatings (e.g., zinc + bitumen) for corrosion protection and internal linings (e.g., cement mortar) for flow efficiency and water quality.

The material itself, cast iron, is an iron-carbon alloy with a carbon content greater than 2%. Ductile iron, specifically, is treated with magnesium to produce spheroidal graphite, enhancing its tensile strength and ductility significantly compared to gray cast iron, which has flake graphite. This makes ductile iron pipes ideal for high-pressure applications like cast iron water main pipe.

Common Cast Iron Pipe Specifications & Applications

| Parameter | Gray Cast Iron Pipe | Ductile Iron Pipe (DI Pipe) | Application Focus |

|---|---|---|---|

| Material Composition | Iron-carbon alloy (>2% C), silicon, manganese, phosphorus, sulfur (Carbon in flake form) | Iron-carbon alloy (Carbon in spheroidal graphite form due to Mg treatment) | Versatility, strength, and corrosion resistance |

| Tensile Strength (MPa) | 100-250 (Brittle) | 420-550 (Ductile, superior impact resistance) | Critical for high-pressure systems |

| Elongation (%) | 0.5-1.0 | 10-15 (More flexible, less prone to fracture) | Seismic areas, unstable ground |

| Typical Diameters (DN) | 50mm - 300mm (for drain, soil) | 80mm - 2600mm (for water, sewer, gas) | From residential cast drain pipe to large industrial conduits |

| Pressure Ratings (PN) | PN6 - PN10 (Low pressure systems) | PN10 - PN100 (High pressure, critical infrastructure) | Water distribution, wastewater, industrial pipelines |

| Corrosion Resistance | Good (improved with coatings) | Excellent (especially with internal/external linings) | Long-term reliability, low maintenance for cast iron conduit |

| Manufacturing Process | Sand casting, spin casting | Centrifugally cast iron pipe (De Lavaud, Super De Lavaud processes) | Ensures uniform wall thickness and strength |

| Standards Compliance | ASTM A74, BS 416, EN 877 | ISO 2531, EN 545, AWWA C151 | Ensures global interoperability and quality for buy cast iron pipe |

| Typical Use Cases | Storm drains, soil pipes, some low-pressure industrial lines, ornamental uses | Potable water supply, wastewater conveyance, raw water, fire protection, industrial plants | From cast iron heating pipes to municipal water mains |

Understanding these distinctions is crucial for selecting the right pipe for your project. For instance, while gray cast iron may suffice for a simple cast drain pipe, a high-pressure municipal water line demands the superior performance of ductile iron.

Application Scenarios: Where Cast Iron Pipes Excel

The versatility of cast iron pipes makes them indispensable across a multitude of sectors. Their inherent strength, durability, and resistance to external pressures and corrosion provide a reliable backbone for critical infrastructure. When you consider to buy cast iron pipe, you're investing in a solution proven in the most demanding environments:

- Water Supply and Distribution: The most common application. Cast iron water main pipe (especially ductile iron) forms the backbone of municipal water networks, reliably transporting potable water over vast distances. Its ability to withstand high internal pressures and external soil loads makes it ideal for buried pipelines, ensuring clean water delivery to homes and businesses.

- Wastewater and Sewer Systems: Cast drain pipe and cast iron drain pipes for sale are extensively used for gravity and pressure sewer lines. Their robust nature resists abrasive waste materials and corrosive gases like hydrogen sulfide, ensuring long-term integrity and preventing leakage, which is critical for public health and environmental protection.

- Industrial Applications: In sectors like petrochemicals, metallurgy, and manufacturing, cast iron pipes handle a variety of fluids, including slurries, chemicals, and cooling water. Their resistance to high temperatures and corrosive substances makes them a preferred choice for process piping. For example, cast iron heating pipes are often found in industrial heating systems due to their thermal stability.

- Fire Protection Systems: Ductile iron pipes are widely used for fire suppression mains due to their high-pressure capabilities and resistance to damage, ensuring a reliable water supply for sprinklers and hydrants in emergencies.

- Gas Distribution: While natural gas distribution has shifted towards plastic pipes in some areas, cast iron pipes (especially ductile iron with specialized coatings) are still used for certain low-pressure gas mains, particularly in older infrastructure or industrial settings, demonstrating their historical reliability as a cast iron conduit.

- Agricultural Irrigation: Large diameter ductile iron pipes are employed in agricultural projects for efficient water conveyance, handling significant volumes and pressures required for modern irrigation techniques.

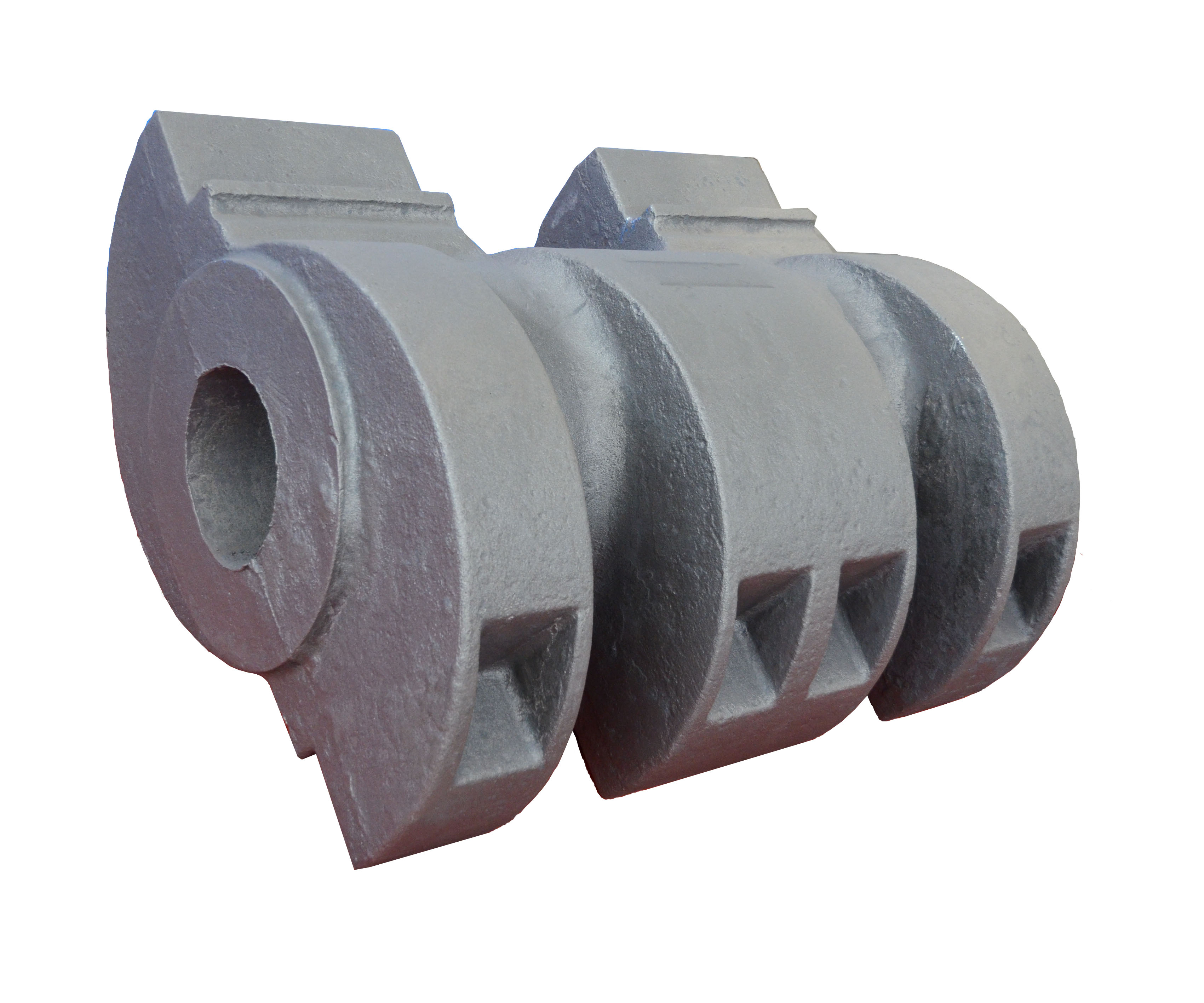

In each scenario, cast iron pipes offer distinct advantages: their long service life (often exceeding 100 years), minimal maintenance requirements, and inherent stability contribute to lower lifecycle costs and enhanced operational efficiency. For applications demanding extreme wear resistance, such as those found in mining, a manufacturer's expertise in specialized castings, like the Accessory for Coal/Mine Crusher Made in Cast Steel, showcases a deep understanding of material science and casting capabilities that extends to high-quality cast iron pipe production.

Crafting Durability: The Manufacturing Process of Cast Iron Pipe

The creation of a high-quality cast iron pipe, particularly centrifugally cast iron pipe, is a sophisticated process that combines advanced metallurgy with precision engineering. This method ensures optimal material distribution, uniform wall thickness, and superior mechanical properties. Here's a simplified breakdown of the manufacturing journey when you seek to buy cast iron pipe:

Raw Material Preparation & Melting

High-quality raw materials, including scrap iron, pig iron, and alloying elements (e.g., ferrosilicon, magnesium for ductile iron), are meticulously selected. These are melted in induction furnaces or cupolas at extremely high temperatures (around 1400-1500°C) to create molten iron. Precise control of the chemical composition at this stage is crucial for the final properties of the cast iron.

Centrifugal Casting (De Lavaud Process)

Molten iron is carefully poured into a rapidly rotating water-cooled metal mold. The centrifugal force evenly distributes the molten metal against the inner surface of the mold, forming a hollow cylinder. This process is particularly effective for producing centrifugally cast iron pipe because it creates a dense, uniform structure free of defects like porosity or inclusions, contributing to superior strength and concentricity for pipes like cast iron water main pipe.

Annealing (for Ductile Iron)

After casting, ductile iron pipes undergo an annealing heat treatment. This process modifies the microstructure of the iron, converting the carbon from a brittle carbide form into the desired spheroidal graphite nodules. This transformation significantly enhances the ductility and impact resistance of the pipe, making it the preferred choice for demanding applications and improving its performance as a cast iron conduit.

Finishing & Machining

Once cooled and annealed, the pipes are precisely cut to specified lengths. The pipe ends are then machined to create the desired joint configuration, such as bell-and-spigot ends for push-on joints or flanges for mechanical connections. This step ensures compatibility with standard fittings and ease of installation for any cast iron outside diameter specification.

Coating & Lining

To enhance corrosion resistance and improve flow characteristics, pipes are typically coated externally and lined internally. Common external coatings include metallic zinc with a finishing layer of bitumen or epoxy. Internal linings often consist of cement mortar, which prevents tuberculation and maintains water quality for cast iron heating pipes and water mains, or polyurethane for corrosive wastewater applications.

Quality Control & Testing

Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes chemical analysis of molten iron, dimensional checks, hydrostatic pressure testing to ensure leak-tightness, tensile strength tests, and visual inspections. Pipes must adhere to strict international standards such as ISO 2531, EN 545 (for water), EN 598 (for wastewater), and AWWA C151 (for ductile iron pressure pipe). These stringent tests ensure that every pipe delivered meets the highest performance and reliability standards.

This meticulous process guarantees that the final product, whether a simple cast drain pipe or a complex industrial line, possesses the inherent strength, durability, and long service life that define high-quality cast iron pipes.

Technical Advantages: Why Cast Iron Remains a Top Choice

The enduring appeal of cast iron pipes, particularly ductile iron, stems from a host of compelling technical advantages that position them as a premier material for diverse infrastructure projects. When deciding to buy cast iron pipe, these benefits are key considerations:

- Exceptional Durability and Longevity: Cast iron pipes are renowned for their incredible lifespan, often exceeding 100 years in service. This is due to their inherent material strength and resistance to degradation from soil conditions and external forces. Many cities still rely on cast iron water mains installed over a century ago.

- High Strength and Impact Resistance: Ductile iron pipes, in particular, possess high tensile strength and significant impact resistance, making them highly resilient to ground movement, pressure surges, and external loads. This minimizes the risk of breakage during installation and throughout their operational life, crucial for sensitive applications like cast iron water main pipe.

- Superior Corrosion Resistance (with Coatings): While iron naturally corrodes, modern cast iron pipes benefit from advanced internal linings (e.g., cement mortar, polyurethane) and external coatings (e.g., metallic zinc, epoxy). These protective layers create a formidable barrier against chemical attack and electrochemical corrosion, extending the pipe's life significantly in aggressive environments, including those for cast iron drain pipes for sale.

- Excellent Pressure Capability: Centrifugally cast iron pipe manufacturing techniques yield pipes with uniform wall thickness and high density, allowing them to withstand substantial internal pressures, making them ideal for high-pressure water transmission and industrial fluid handling.

- Cost-Effectiveness Over Lifecycle: Although initial procurement costs for cast iron pipes might be higher than some plastic alternatives, their unparalleled longevity, minimal maintenance requirements, and resistance to damage result in significantly lower lifecycle costs. The long service life reduces the frequency and expense of replacement projects.

- Ease of Installation and Joint Reliability: Modern push-on joints for ductile iron pipes offer rapid and secure installation, even in challenging conditions. The gasketed joints accommodate minor ground movement and thermal expansion, ensuring long-term seal integrity. Flanged joints provide robust connections for specialized industrial setups.

- Resistance to Permeation: Unlike some plastic pipes, cast iron is impermeable to volatile organic compounds (VOCs) and petroleum products, protecting water quality in contaminated ground conditions. This makes it a safer choice for potable water lines where ground contamination is a concern.

- Environmental Sustainability: Cast iron is a highly recyclable material, with a significant percentage of new pipes manufactured from recycled content. This reduces the environmental footprint and promotes a circular economy.

These advantages collectively underscore why cast iron, particularly ductile iron, remains a trusted and high-performing solution for vital infrastructure worldwide. Its proven track record in diverse applications, from high-pressure water supply to resilient cast drain pipe systems, affirms its status as a material of choice for demanding engineering projects.

Manufacturer Comparison & Trust: Choosing Your Cast Iron Pipe Partner

When seeking to buy cast iron pipe, selecting the right manufacturer is as crucial as choosing the right material. A reputable manufacturer offers not just a product, but a partnership built on quality, expertise, and reliability. Key factors to consider include:

- Industry Certifications & Standards: Ensure the manufacturer adheres to international quality management systems like ISO 9001 and produces pipes compliant with relevant standards (e.g., ISO 2531, EN 545, AWWA C151 for ductile iron; ASTM A74 for gray cast iron). Certifications from independent bodies like NSF International (for potable water applications) are also highly valuable.

- Experience and Track Record: Look for manufacturers with a long history of successful projects and a proven track record in producing high-quality castings. Years of service in the industry often correlate with deep understanding of material science and application challenges, whether for cast ductile iron pipe or specialized industrial components.

- Quality Control and Testing Procedures: A trustworthy factory will have stringent internal quality control at every stage of production, from raw material inspection to final product testing (e.g., hydrostatic testing, dimensional checks, metallurgical analysis). Ask for details on their testing protocols.

- Technological Capabilities: Assess their manufacturing technology. Factories utilizing advanced methods like centrifugally cast iron pipe production demonstrate a commitment to superior product quality and efficiency.

- Customer Support and Technical Assistance: A good partner provides comprehensive pre-sales consultation, technical data, and reliable after-sales support, including guidance on installation, maintenance, and problem-solving for products like cast iron conduit.

- Logistics and Delivery Reliability: Timely and secure delivery is crucial for project success. Inquire about their logistical capabilities, lead times, and packaging standards to ensure products like cast iron outside diameter pipes arrive in optimal condition.

For instance, a company like Casiting, while prominently featuring products such as the Accessory for Coal/Mine Crusher Made in Cast Steel, demonstrates a core competency in advanced casting techniques and material engineering for demanding applications. This expertise in high-wear, high-stress components for the mining industry directly translates to their ability to produce highly durable and reliable cast iron products. Their focus on rigorous quality control and understanding of material performance in harsh environments underscores their capability as a trustworthy source for various cast metal solutions, including high-grade cast iron pipes for diverse sectors.

Customization Solutions: Tailoring Cast Iron Pipes to Your Needs

One of the significant advantages of working with experienced cast iron pipe manufacturers is the ability to obtain customized solutions tailored to specific project requirements. Standard pipe sizes and types cover most applications, but certain projects demand bespoke features. When you choose to buy cast iron pipe from a flexible supplier, you can often specify:

- Specific Coatings and Linings: Beyond standard cement mortar lining and zinc/bitumen coating, projects may require specialized epoxy coatings for enhanced chemical resistance, polyurethane lining for abrasive slurries, or ceramic linings for extreme wear conditions.

- Non-Standard Lengths: While pipes typically come in standard lengths, custom lengths can reduce the number of joints and simplify installation in confined spaces or unique layouts.

- Special Fittings and Adapters: Complex pipeline networks often need custom fabricated fittings, bends, reducers, or adapters to connect different pipe materials or sizes seamlessly.

- Pressure Ratings and Wall Thicknesses: For extremely high-pressure applications or unique load-bearing requirements, pipes can be manufactured with customized wall thicknesses to meet specific engineering demands, especially for large cast iron outside diameter pipes.

- Joint Variations: Beyond standard push-on or flanged joints, some applications might require specialized locking joints, restrained joints, or welded connections for specific operational needs.

Collaborating with a manufacturer capable of such customization ensures that your piping system is optimized for performance, longevity, and cost-efficiency, eliminating the need for costly field modifications.

Application Case Studies: Cast Iron Pipes in Action

The reliability and longevity of cast iron pipes are best demonstrated through their successful deployment in real-world scenarios. These case studies highlight why engineers and contractors continue to buy cast iron pipe for critical infrastructure:

Case Study 1: Municipal Water Main Replacement in a Major City

Challenge: An aging gray cast iron water main, installed over 80 years ago, frequently burst, causing significant water loss and disruption in a densely populated urban area. The ground conditions were unstable, and minimizing traffic disruption was critical.

Solution: The municipality chose to replace the old line with large-diameter (DN600) cast ductile iron pipe using push-on joints. The ductile iron's superior strength and flexibility allowed it to withstand ground movement, while the ease of push-on joint installation significantly reduced construction time. The internal cement mortar lining ensured continued water quality and excellent flow characteristics. This project, completed efficiently, restored reliable water supply and is expected to last well over 100 years, demonstrating the long-term value of ductile iron as a cast iron water main pipe.

Case Study 2: Industrial Wastewater Treatment Plant Upgrade

Challenge: A petrochemical plant needed to upgrade its highly corrosive wastewater conveyance system, which had previously suffered frequent failures with alternative materials. The system carried high-temperature, acidic effluent.

Solution: Specialized ductile iron pipes with internal polyurethane linings and external epoxy coatings were selected. The robust ductile iron provided the structural integrity to handle high pressures, while the custom lining offered exceptional chemical resistance against the aggressive effluent. This solution drastically reduced maintenance downtime and extended the system's operational life, proving ductile iron's versatility in harsh industrial environments, even more demanding than typical cast drain pipe scenarios.

Case Study 3: New District Heating Network in a Cold Climate

Challenge: A new urban development required a robust and thermally efficient district heating network capable of operating reliably in sub-zero temperatures and high pressures.

Solution: The project opted for pre-insulated cast iron heating pipes, specifically ductile iron, due to its excellent thermal conductivity, ability to withstand thermal cycling, and inherent durability. The robust joints and pipe material ensured minimal heat loss and leak protection, even under significant temperature fluctuations. This application underscored cast iron's role in energy-efficient utility systems.

These examples illustrate how cast iron pipes, particularly the advanced ductile iron variants, consistently deliver superior performance, longevity, and cost-effectiveness in diverse and demanding applications. Customers report significant reductions in maintenance costs and increased system reliability after upgrading to high-quality cast iron solutions.

Frequently Asked Questions (FAQ) about Cast Iron Pipes

The primary difference lies in their microstructure. Gray cast iron has carbon in flake form, making it brittle. Ductile iron, treated with magnesium during manufacturing, has carbon in spheroidal (nodular) form, giving it significantly higher ductility, tensile strength, and impact resistance. This makes ductile iron much more resistant to fracture and preferred for high-pressure and critical applications like cast iron water main pipe.

For ductile iron pipes, commonly referenced international standards include ISO 2531 (Ductile iron pipes, fittings, accessories and their joints for water or gas applications), EN 545 (for water), EN 598 (for wastewater), and AWWA C151 (for ductile iron pressure pipe in North America). For gray cast iron soil pipes (like cast drain pipe), look for ASTM A74 or EN 877. Adherence to these standards ensures product quality and compatibility.

Cast iron pipes, especially ductile iron with modern coatings and linings, have an exceptional service life. They are commonly expected to last 75-100 years, and many existing installations have already exceeded 100 years. This longevity contributes to their low lifecycle cost, making them a wise investment when you buy cast iron pipe.

Centrifugally cast iron pipe refers to a manufacturing method where molten iron is poured into a rapidly rotating mold. The centrifugal force distributes the metal evenly, creating a pipe with uniform wall thickness, high density, and excellent concentricity. This process significantly improves the mechanical properties of the pipe, reducing defects and enhancing its strength and pressure resistance, making it superior to static casting for pressure applications like cast iron heating pipes and water mains.

While iron can corrode, modern cast iron pipes, particularly ductile iron, are highly resistant due to advanced protective measures. External coatings (e.g., metallic zinc, epoxy) provide active and passive corrosion protection from soil. Internal linings (e.g., cement mortar for water, polyurethane for wastewater) prevent internal corrosion and tuberculation, maintaining flow capacity and water quality. These measures ensure extended life for products like cast iron conduit.

Yes, cast iron is 100% recyclable. It is a highly sustainable material, with a significant portion of new cast iron pipes manufactured from recycled scrap iron. This reduces the demand for virgin raw materials and minimizes environmental impact, making it an environmentally responsible choice when you buy cast iron pipe.

The delivery cycle for custom or large-volume cast iron pipe orders can vary based on the specific requirements, order size, and manufacturer's production schedule. Typically, standard products might ship within 4-6 weeks, while highly customized pipes (e.g., specific coatings, non-standard cast iron outside diameter, complex fittings) could require 8-12 weeks or more. It's always best to consult directly with the factory for an accurate lead time based on your precise order specifications. Reliable manufacturers also offer robust packaging and logistics support to ensure safe and timely delivery.

Delivery Cycle and Quality Assurance: Our Commitment

At our core, we understand that timely delivery and uncompromising quality are paramount. While the Accessory for Coal/Mine Crusher Made in Cast Steel exemplifies our precision in specialized castings, our commitment extends to all our products, including comprehensive cast iron pipe solutions. We maintain efficient production schedules, leveraging our advanced casting facilities to minimize lead times for standard and custom orders. Typical delivery cycles for high-quality cast iron pipe vary based on order volume and customization, but our logistics team works diligently to ensure on-time dispatch.

Every product undergoes stringent quality control, including material composition analysis, dimensional accuracy checks, and performance testing, adhering to international standards such as ISO 9001. We provide comprehensive warranty commitments against manufacturing defects, reflecting our confidence in the durability and reliability of our products. Our dedicated customer support team is always available to assist with any technical queries, installation guidance, or after-sales service, ensuring a seamless experience from inquiry to long-term operation. When you buy cast iron pipe from us, you're investing in a product backed by decades of expertise and a strong commitment to customer satisfaction.

Conclusion: The Enduring Legacy of Cast Iron Pipes

From foundational water infrastructure to specialized industrial applications, the legacy of cast iron pipes continues to thrive, significantly propelled by the advancements in ductile iron technology. The decision to buy cast iron pipe is an investment in unparalleled durability, resilience, and long-term cost-effectiveness. Their superior strength, corrosion resistance (especially with modern coatings), and environmental benefits make them an indispensable choice for engineers and municipalities worldwide.

As urbanization accelerates and infrastructure demands grow, the demand for robust and reliable piping solutions will only increase. With continuous innovation in manufacturing processes like centrifugally cast iron pipe and the development of advanced protective coatings, cast iron remains at the forefront of sustainable and high-performance pipeline materials, ready to meet the challenges of the 21st century and beyond. Whether for a critical cast iron water main pipe or a dependable cast drain pipe system, the choice for cast iron reflects a commitment to quality that stands the test of time.

References and Further Reading:

- Ductile Iron Pipe Research Association (DIPRA): "Handbook of Ductile Iron Pipe." https://www.dipra.org/technical-information/handbook

- American Water Works Association (AWWA): "AWWA Standards for Ductile Iron Pipe." https://www.awwa.org/Store/Product-Detail/productId/76973977

- International Organization for Standardization (ISO): "ISO 2531: Ductile iron pipes, fittings, accessories and their joints for water or gas applications." https://www.iso.org/standard/70659.html

- Journal of Water Resources Planning and Management: "Life Cycle Cost Analysis of Water Main Materials." (Often discusses cast iron vs. alternatives in terms of longevity and maintenance). Specific article links vary, but general search on ASCE library is advised. https://ascelibrary.org/journal/jwrmd5

- Water Environment Federation (WEF): Resources on pipe material selection for wastewater applications. https://www.wef.org/resources/publications/books/

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025