- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nën . 22, 2024 07:33 Back to list

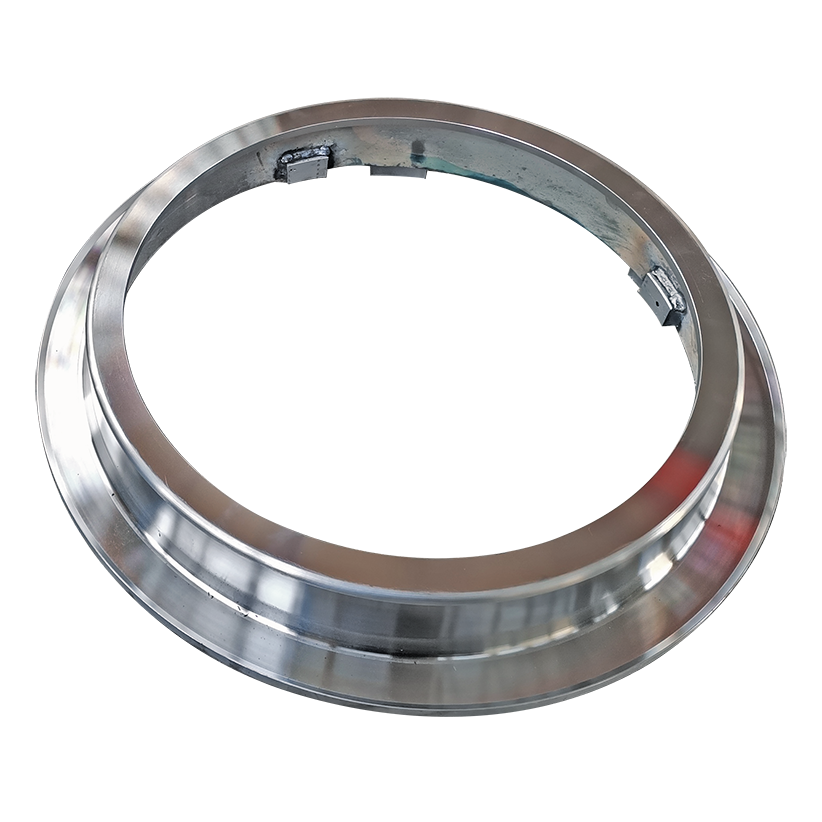

mold pallet

Understanding Mold Pallets An Essential Component in Manufacturing

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One of the critical components that enhance these aspects is the mold pallet. This article explores the significance of mold pallets in the production process, their types, benefits, and best practices for their use.

What are Mold Pallets?

Mold pallets, often referred to as mold bases or mold carriers, are specialized platforms used to hold and support molds during the manufacturing process. They are integral to industries such as plastics, automobile parts, and even metal casting. The primary function of a mold pallet is to provide stability and a secure environment for the mold while it is being filled with material or subjected to various manufacturing processes.

Types of Mold Pallets

There are different types of mold pallets, each designed to meet specific industry needs and mold configurations. The two primary categories are

1. Standard Mold Pallets These are commonly used in the manufacturing of simple molds. They come in various sizes and materials, including steel and aluminum, to accommodate different weight and size requirements.

2. Customized Mold Pallets For more complex manufacturing processes, custom mold pallets may be designed to fit unique mold shapes and sizes. These pallets often include additional features, such as built-in cooling channels or heated elements, to optimize the production process.

Benefits of Using Mold Pallets

The implementation of mold pallets in manufacturing processes offers several significant advantages

1. Enhanced Stability Mold pallets provide a stable and secure base for molds, reducing the risk of vibration or movement during the manufacturing process, which can lead to defects or inaccuracies in the final product.

mold pallet

2. Improved Efficiency By utilizing mold pallets, manufacturers can streamline their production process. The ability to easily transport molds between different stages of production minimizes downtime and enhances throughput.

3. Cost-effectiveness Enhanced manufacturing efficiency translates into reduced labor costs and material waste. Additionally, with custom mold pallets, companies can optimize their mold design, further driving down costs in the long run.

4. Versatility Mold pallets can be designed or modified to accommodate a wide range of mold designs and manufacturing processes. This flexibility makes them an invaluable asset for companies that work with multiple product lines or undergo frequent design changes.

Best Practices for Using Mold Pallets

To maximize the benefits that mold pallets offer, manufacturers should follow some best practices

1. Regular Maintenance Regularly inspect and maintain mold pallets to ensure they remain in optimal condition, preventing costly delays in production due to equipment failure.

2. Proper Alignment Ensure that molds are properly aligned on the pallets. Misalignment can lead to uneven pressure distribution during the manufacturing process, leading to defects.

3. Use Appropriate Materials Choose the right material for the mold pallets based on the specific requirements of the manufacturing process. Consider the weight of the molds, the temperature conditions, and any cleaning processes that may be required.

4. Train Staff Provide comprehensive training for staff involved in the setup and handling of mold pallets. Proper handling techniques can help avoid damage to both the pallets and the molds.

Conclusion

As manufacturing processes continue to evolve, the importance of mold pallets cannot be overstated. They play a crucial role in enhancing manufacturing efficiency, ensuring product quality, and reducing costs. By understanding their types, benefits, and best practices for use, manufacturers can fully leverage mold pallets as a vital component in their production lines. Investing in quality mold pallets and adhering to best practices not only supports operational goals but also drives innovation and competitiveness in the marketplace.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025