- Moafrika

- Sealbania

- Seamharic

- Searabia

- Searmenia

- Se-Azerbaijani

- Sebasque

- Sebelarusia

- Benghali

- Sebosnia

- Se-Bulgaria

- Secatalan

- Sebuano

- China

- China (Taiwan)

- Corsican

- Secroatia

- Czech

- Sedanishe

- Se-Dutch

- Senyesemane

- Esperanto

- Seestonia

- Sefinnishe

- Sefora

- Sefrisia

- Segalician

- Segeorgia

- Sejeremane

- Segerike

- Segujarati

- Secreole sa Haiti

- hausa

- siwaiian

- Seheberu

- Che

- Miao

- Se-Hungary

- Seiceland

- igbo

- Seindonesia

- irish

- Setaliana

- Sejapane

- Se-Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Sekorea

- Sekurdish

- Sekyrgyz

- Mosebetsi

- Selatine

- Selatvia

- Selithuania

- Se-Luxembourgish

- Semacedonia

- Malgashi

- Semalay

- Semalayalam

- Semalta

- Semaori

- Marathi

- Mongolian

- Myanmar

- tsa Nepali

- Norwegian

- Norwegian

- Occitan

- Sepashto

- Sepersia

- Sepolishe

- Sepotoketsi

- Sepunjabi

- Seromania

- Serussia

- Sesamoa

- Segaeli sa Scotland

- Seserbia

- Senyesemane

- Seshona

- Sindhi

- Sesinhala

- Seslovak

- Seslovenia

- Somalia

- Sepanish

- Sesundanese

- Seswahili

- Seswedishe

- Setagalog

- Se-Tajik

- Setamil

- Setatare

- Setelugu

- Sethai

- Se-Turkey

- Turkmen

- Seukraine

- Seurdu

- Uighur

- Seuzbek

- Sevietnam

- Welsh

- Thusa

- Yiddish

- Yoruba

- Sezulu

Mar . 11, 2025 14:21 Khutlela lethathamong

The Integration of Hot Water Heat Exchangers with IoT Platforms

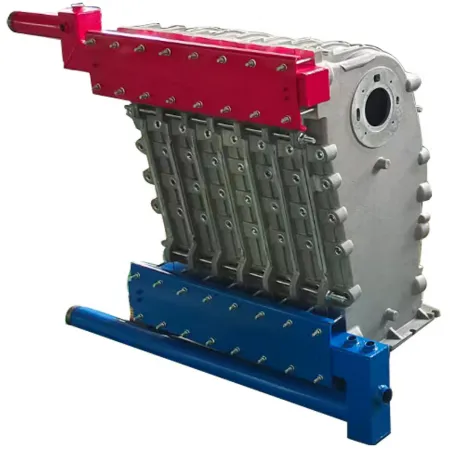

In today’s rapidly evolving technological landscape, industries are increasingly adopting high pressure heat exchangers and liquid heat exchangers to improve efficiency, reduce energy consumption, and lower costs. One of the most innovative trends in this space is the integration of heat exchangers with Internet of Things (IoT) platforms. This integration takes traditional systems to the next level, offering real-time monitoring, enhanced performance, and better control over heating processes. The result is not just energy savings but also improved operational reliability and sustainability, particularly in environments like refinery water cooled heat exchangers.

With the growing demand for smarter and more efficient systems, liquid heat exchangers have found their place at the forefront of IoT-enabled solutions. These smart systems allow for seamless communication between components, which can then be used to gather and analyze data that helps optimize performance, detect issues early, and predict maintenance needs before they arise. The integration of IoT technology into hot water heat exchangers is transforming industries that rely heavily on heating and cooling processes, such as manufacturing, residential heating, and chemical refineries.

Streamlining Performance with Hot Water Heat Exchangers

The combination of high pressure heat exchangers and IoT platforms enables the continuous monitoring of system performance. Sensors embedded in the liquid heat exchanger detect factors such as temperature, flow rates, pressure, and energy usage. This data is transmitted in real time to a central platform, where it is analyzed and can be accessed remotely by engineers or operators.

This level of connectivity makes it possible to track the performance of refinery water cooled heat exchangers or any industrial heat exchange system. Instead of relying on periodic manual checks or reports, IoT integration provides an ongoing view of system efficiency. Operators can make quick adjustments based on up-to-the-minute information, ensuring the heat exchangers are operating at peak efficiency, minimizing waste, and avoiding potential system failures. The ability to detect inefficiencies early is invaluable for reducing energy costs and extending the life cycle of your heat exchangers.

Enhanced Predictive Maintenance with Heat Exchangers

One of the most significant advantages of integrating IoT with high pressure heat exchangers is the ability to implement predictive maintenance strategies. By continuously collecting data from the liquid heat exchanger, operators can use sophisticated algorithms to predict when a part is likely to fail or when maintenance is required.

For example, by monitoring the vibration levels, temperature fluctuations, and pressure changes within the system, IoT platforms can alert the operator to potential problems. If a component is beginning to show signs of wear or stress, a notification can be sent out, allowing maintenance crews to fix the issue before it leads to a full system breakdown. This proactive approach minimizes downtime and the need for costly emergency repairs, ensuring smooth and continuous operation for refinery water cooled heat exchangers and other systems reliant on heat exchange technology.

Moreover, predictive maintenance helps operators avoid unnecessary maintenance tasks, reducing the costs associated with over-servicing and maximizing the use of resources. As a result, businesses that incorporate IoT-enabled liquid heat exchangers can achieve a significant return on investment.

Heat Exchangers:Improved Energy Efficiency and Cost Savings

Energy efficiency is one of the key drivers behind the adoption of IoT-enabled high pressure heat exchangers. By providing continuous feedback on energy usage, liquid heat exchangers can be optimized to use less energy, reduce waste, and operate more sustainably. Operators can adjust settings in real time to maintain the desired temperature or heat output without unnecessary power consumption.

The IoT platform can provide insights into energy trends, highlighting peak usage periods and pinpointing when the system is running inefficiently. With this data at their disposal, companies can adjust schedules, make operational changes, and even automate adjustments based on pre-set conditions. As energy costs continue to rise, the ability to optimize energy consumption through smart systems is becoming more essential for companies looking to maintain profitability.

For industries using refinery water cooled heat exchangers, the energy savings can be substantial. These systems are often used in environments where large amounts of hot water are required, such as in industrial heating processes. The integration of IoT technology enables energy efficiency improvements, reducing operational costs and boosting overall system performance.

Liquid Heat Exchangers: Maximizing Operational Lifespan and Reliability

The combination of high pressure heat exchangers and IoT technology enhances the operational lifespan of heat exchangers by ensuring they are properly maintained and optimized. Liquid heat exchangers are essential for keeping fluids within a desired temperature range, and over time, regular wear and tear can reduce their effectiveness. By utilizing IoT-powered systems, you can track every variable that affects the efficiency and reliability of the heat exchanger, helping to prevent wear from developing into a serious problem.

For industries that rely heavily on these systems—such as refineries, factories, or large-scale residential heating—the ability to maintain equipment in optimal condition is crucial. By keeping track of usage, maintenance, and performance in real time, companies can extend the life of their refinery water cooled heat exchangers and liquid heat exchangers, reducing the frequency of expensive replacements and ensuring the long-term reliability of the system.

Additionally, integrating IoT platforms with high pressure heat exchangers helps companies stay ahead of regulatory compliance. Many industries are required to meet specific operational standards for safety, efficiency, and environmental impact. With the data provided by IoT platforms, these requirements can be met more effectively, helping businesses avoid penalties and costly fines.

At our company, we offer a range of advanced liquid heat exchangers and high pressure heat exchangers that are fully compatible with IoT integration. Our products are designed to optimize efficiency, reduce energy consumption, and improve overall performance, making them ideal for industrial and commercial applications.

Our refinery water cooled heat exchangers are built to withstand high demands and offer long-lasting performance, while our IoT-enabled technology allows for seamless integration into existing systems. With our products, you can take advantage of predictive maintenance, real-time monitoring, and enhanced energy efficiency—all designed to reduce operational costs and extend the lifespan of your equipment.

Ready to experience the future of heat exchange systems? Visit our website and purchase our cutting-edge liquid heat exchangers and high pressure heat exchangers today. Maximize your system’s performance and join the growing number of businesses adopting smart, sustainable heating solutions!

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

LitabaJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

LitabaJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

LitabaJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

LitabaJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

LitabaJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

LitabaJun.24,2025