- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Desemba . 09, 2024 22:38 Back to list

Exploring Bronze Investment Casting Processes and Leading Industry Factories

The Role of Bronze Investment Casting Factories in Modern Manufacturing

Bronze investment casting factories play a crucial role in the manufacturing sector, particularly in producing high-value components for various industries. The investment casting process, also known as lost-wax casting, allows for the production of intricate and precise metal parts that meet the demanding requirements of modern machinery and technology. This article explores the significance of bronze investment casting, the manufacturing process, its applications, and the future of this industry.

Understanding Bronze Investment Casting

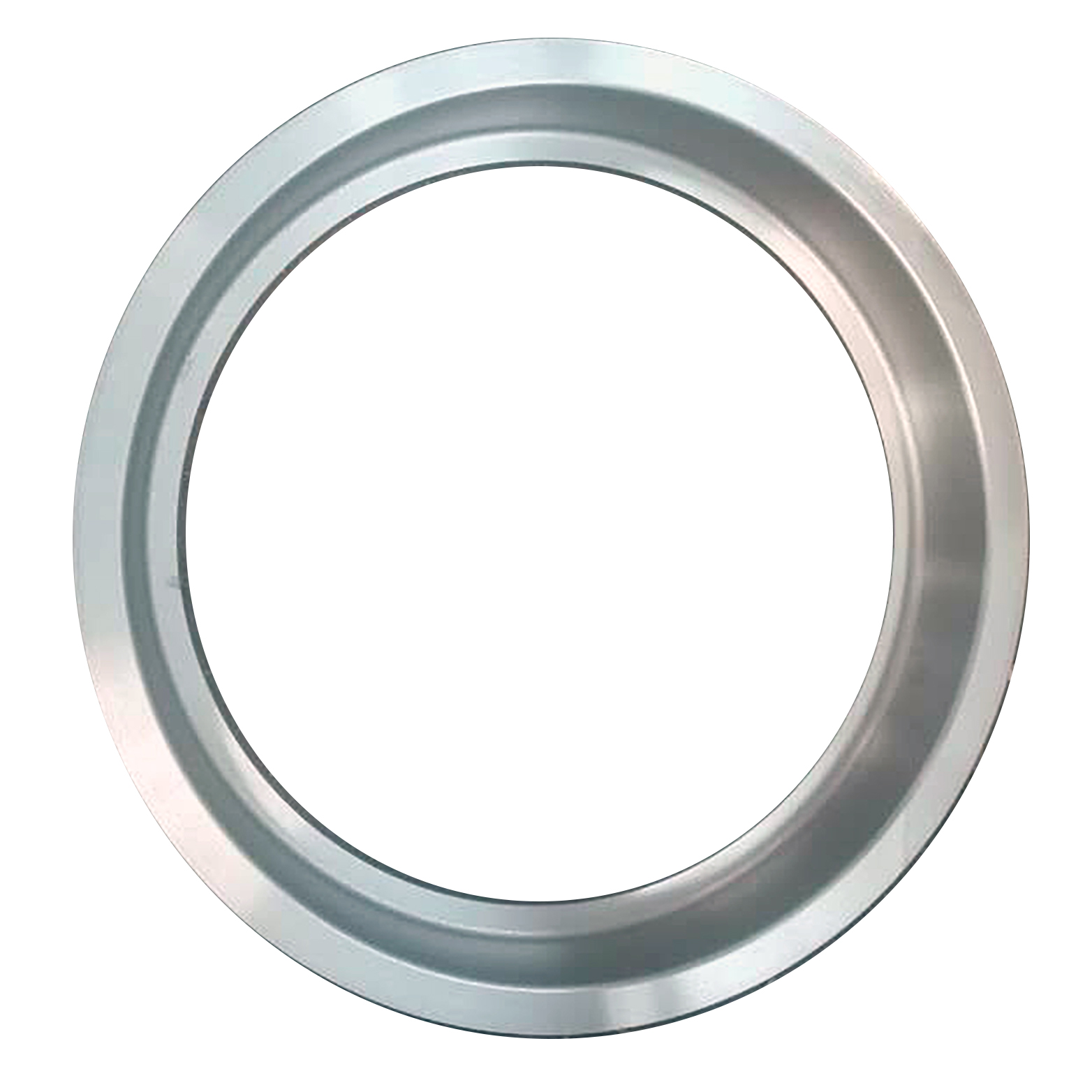

Bronze, an alloy primarily composed of copper and tin, is highly valued due to its excellent mechanical properties, corrosion resistance, and aesthetic appeal. These characteristics make bronze an ideal material for various applications, such as marine hardware, sculptures, industrial components, and decorative items. The investment casting process further enhances the usability of bronze by allowing manufacturers to create complex shapes that would be impossible to achieve through traditional casting methods.

The Investment Casting Process

The investment casting process consists of several stages, beginning with the creation of a wax pattern. The wax pattern is designed to form the exact shape of the final product. Once the pattern is ready, it is coated with a ceramic material to create a mold. After the ceramic mold has hardened, the wax is melted and drained out, leaving a hollow cavity in the shape of the desired part.

Next, molten bronze is poured into the mold to fill the cavity. Following the cooling period, the mold is broken away, revealing the bronze casting. This method allows for high dimensional accuracy and a smooth surface finish, reducing the need for extensive machining or finishing operations.

Applications of Bronze Investment Casting

Bronze investment casting is utilized across a wide range of industries. In the marine sector, for example, bronze components are used for rudders, propellers, and various fittings due to bronze's resistance to saltwater corrosion. In the aerospace and automotive industries, manufacturers rely on investment casting to produce lightweight yet strong parts, such as brackets, housings, and engine components that can withstand extreme pressures and temperatures.

bronze investment casting factories

Additionally, bronze investment casting is prominent in the art world, where artists and sculptors employ this technique to create intricate sculptures and decorative pieces. The aesthetic qualities of bronze combined with the precision of investment casting allow for detailed designs that capture fine details and textures.

Economic Significance and Environmental Considerations

Bronze investment casting factories contribute significantly to the economy by providing jobs and supporting local industries. The precision and efficiency of investment casting can result in reduced production costs, allowing businesses to remain competitive while maintaining high product quality.

However, the investment casting industry must also address environmental concerns related to metal casting. Factories are increasingly adopting sustainable practices, such as recycling materials, reducing waste, and utilizing cleaner energy sources. Innovations in technologies, such as 3D printing for creating patterns, also enable more efficient production processes that minimize resource consumption.

Future Trends in Bronze Investment Casting

As technology continues to advance, the future of bronze investment casting factories looks promising. The integration of automation and smart manufacturing processes is likely to enhance efficiency and accuracy in production. Additionally, the development of advanced alloys and materials will allow for even greater versatility in applications.

Furthermore, the growing demand for customized products is driving factories to adopt more flexible production methods, enabling them to cater to specific customer needs without sacrificing quality. The use of computer-aided design (CAD) and simulation tools will facilitate the design and testing phases, leading to faster and more reliable production cycles.

Conclusion

Bronze investment casting factories represent a key element in modern manufacturing, providing high-quality, precise components for a diverse array of industries. The investment casting process offers distinct advantages, including intricate designs and reduced need for machining, making it an indispensable technique in various applications. As the industry continues to innovate and adapt to changing economic and environmental landscapes, bronze investment casting will remain a vital contributor to the global manufacturing ecosystem.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025