- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Desemba . 05, 2024 14:52 Back to list

casting metal supply

Understanding Casting Metal Supply A Comprehensive Overview

The metal casting industry is a vital part of modern manufacturing, playing a crucial role in the production of various components used across a plethora of sectors, from automotive to aerospace and beyond. At the heart of this industry lies the concept of casting metal supply, which encompasses the sourcing, processing, and distribution of metals used in casting procedures. This article aims to provide a comprehensive overview of casting metal supply, its importance, challenges, and future trends.

What is Metal Casting?

Metal casting is a process in which molten metal is poured into a mold to create a solidified part. This technique allows for the production of complex shapes and sizes that would be difficult or cost-prohibitive to achieve through other manufacturing processes. There are various types of casting methods, including sand casting, investment casting, and die casting, each suited to specific applications and materials.

The Supply Chain of Casting Metal

The casting metal supply chain is composed of several critical components, including raw material suppliers, foundries, and distributors

. The process often begins with the sourcing of raw materials, primarily alloys like aluminum, iron, and copper, which are essential for the casting process. Suppliers play a key role in ensuring that foundries receive high-quality materials that meet industry standards.Once the raw materials are procured, they are delivered to foundries where the actual casting takes place. Foundries convert these raw materials into molten metal, which is then poured into molds to form various products. After the casting process, additional operations may be required, such as machining, finishing, and quality control, to ensure that the final products meet specifications.

Distribution is another critical aspect of casting metal supply, as finished products need to be delivered to manufacturers and end-users in a timely manner. Efficient logistics and supply chain management are crucial in maintaining the flow of materials and products, as delays can impact production schedules and overall project timelines.

Challenges in Metal Casting Supply

casting metal supply

While the metal casting industry is essential to modern manufacturing, it faces several challenges. One of the most significant issues is the fluctuation of raw material prices, which can impact production costs and profit margins for foundries. Additionally, environmental regulations surrounding emissions and waste management are becoming increasingly stringent, forcing foundries to adapt their processes to minimize their ecological footprint.

Another challenge is the skilled labor shortage affecting the industry. As more experienced workers retire, there is a growing need for trained professionals who can operate casting machinery and ensure quality control. Addressing this skills gap is critical to maintaining a competitive edge.

Emerging Trends in Casting Metal Supply

As the manufacturing landscape evolves, so too does the casting metal supply chain. One of the most noteworthy trends is the adoption of advanced technologies such as automation, robotics, and even artificial intelligence. These innovations can streamline processes, enhance precision, and improve safety within foundries.

Moreover, sustainability is becoming a driving force behind many casting operations. Foundries are increasingly seeking ways to reduce energy consumption, recycle scrap metal, and develop eco-friendly casting materials. These efforts not only comply with regulations but also appeal to environmentally conscious clients.

The shift towards digitalization is another prominent trend, with many foundries implementing sophisticated software solutions for process control, inventory management, and production planning. This data-driven approach enables better decision-making and improves overall efficiency.

Conclusion

Casting metal supply is an integral part of the manufacturing ecosystem, providing essential components across various industries. While it faces challenges such as fluctuating material prices, labor shortages, and environmental regulations, the sector is adapting through technology and sustainability initiatives. As the industry continues to evolve, the emphasis on innovation and efficiency will be key to its future success, ensuring that it remains a cornerstone of modern production for years to come.

-

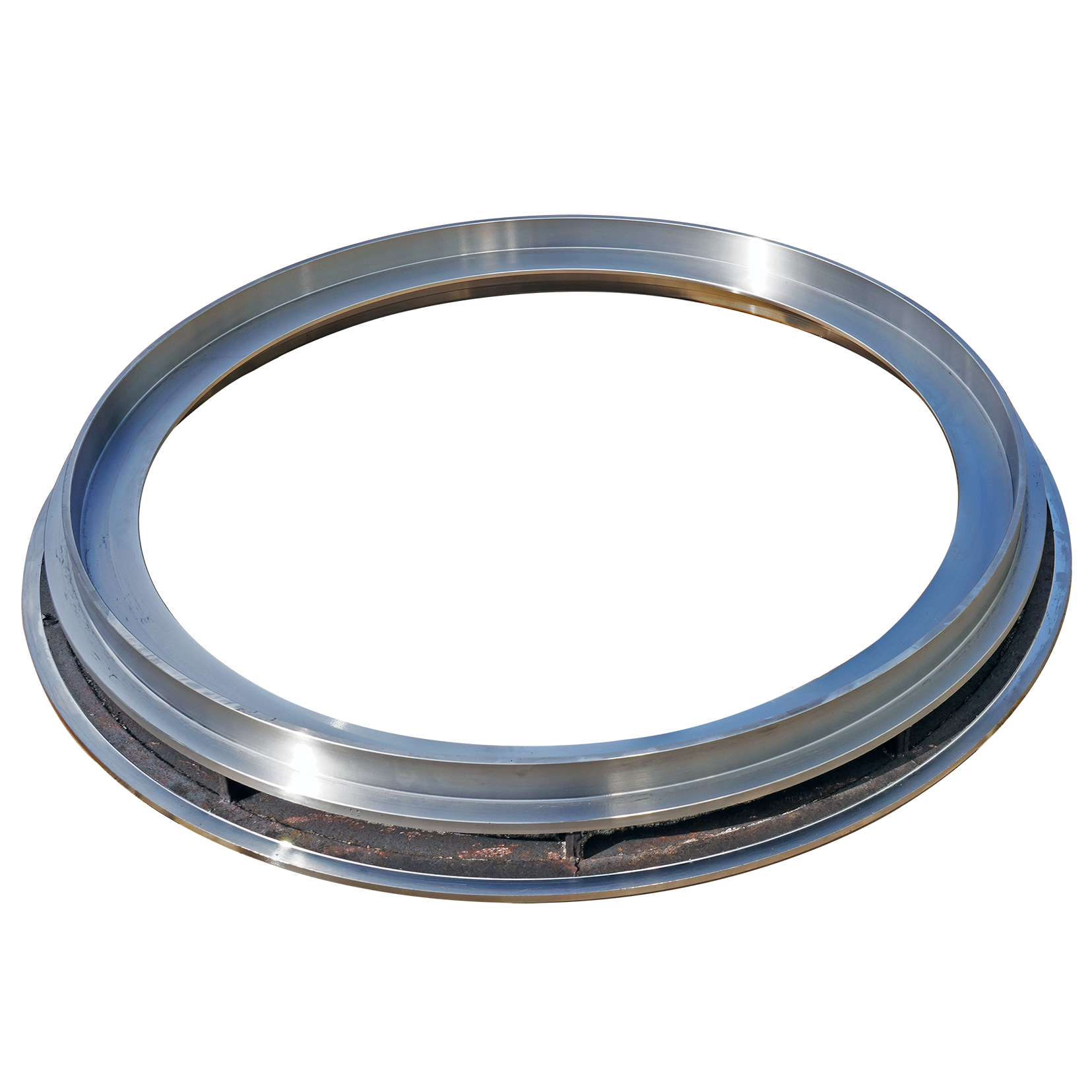

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025