- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oktoba . 16, 2024 16:53 Back to list

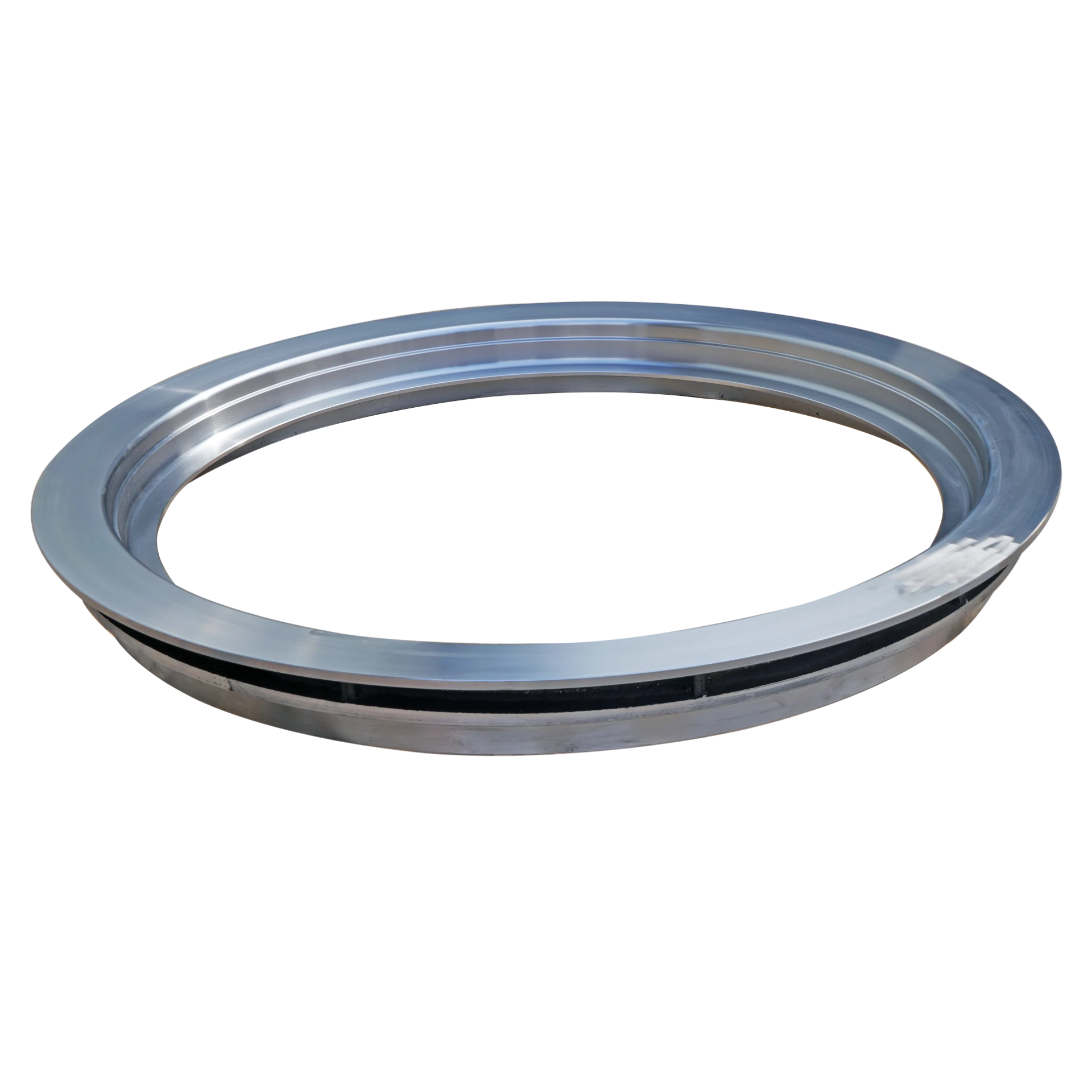

Design of Fiber Reinforced Concrete Pipe Mold for Efficient Bottom Ring Production

The Importance of Fibre Reinforced Concrete Pipe Mould Bottom Rings

In the construction and civil engineering fields, the use of fibre reinforced concrete (FRC) has gained significant traction due to its enhanced properties compared to conventional concrete. Particularly when it comes to manufacturing pipes, the integration of fibre reinforcement offers substantial benefits, especially in the bottom rings of pipe moulds.

Understanding Fibre Reinforced Concrete

Fibre reinforced concrete is created by incorporating fibrous materials into conventional concrete. This reinforcement can take various forms, including steel fibres, glass fibres, synthetic fibres, or natural fibres. The primary objective of using fibres is to improve the structural integrity, durability, and performance of concrete under various loading conditions. It helps to prevent cracking and enhances the tensile strength of the concrete, making it particularly valuable in applications such as pipes that are subject to varied stresses.

The Role of Pipe Moulds in Production

In the production of concrete pipes, moulds play a crucial role in determining the shape, size, and final quality of the product. The bottom ring of a pipe mould is especially significant as it ensures stability during the pouring and curing process. A well-designed bottom ring helps to minimize deformation and ensures that the finished pipe meets the required specifications for strength and durability.

Advantages of Using Fibre Reinforced Concrete in Pipe Mould Bottom Rings

1. Enhanced Structural Integrity The primary advantage of incorporating fibres into the concrete mix for the mould's bottom ring is the improvement in its structural integrity. FRC exhibits reduced crack propagation, making the mould resistant to the stresses it encounters during production.

fibre reinforced concrete pipe mould bottom ring

2. Improved Durability FRC demonstrates superior durability compared to conventional concrete. This durability translates to longer life spans for moulds, reducing the need for frequent replacements and maintenance. This not only leads to cost savings but also ensures consistent production quality over time.

3. Lightweight Solutions By using fibre reinforcement, manufacturers can often reduce the amount of concrete required for the mould, resulting in a lighter bottom ring. This can simplify handling, reduce transportation costs, and minimize the effort required for assembly and disassembly.

4. Cost-Effectiveness Although the initial cost of fibre reinforced concrete may be higher than conventional concrete, the long-term benefits significantly outweigh the costs. The durability and reduced need for repairs or replacements lead to lower overall expenses.

5. Increased Production Efficiency The stability provided by a fibre reinforced bottom ring enhances the efficiency of the manufacturing process. It minimizes blockages and irregularities during pouring, leading to faster production cycles and improved output quality.

6. Versatility Fibre reinforced concrete can be tailored for specific applications by adjusting the type and quantity of fibres used. Hence, manufacturers can create bottom rings that are optimized for various environmental conditions and stress factors often faced in pipeline applications.

Conclusion

The integration of fibre reinforced concrete in the production of pipe mould bottom rings presents a revolutionary advancement in the manufacturing process within the construction industry. The advantages extend far beyond merely improving the moulds themselves; they cascade through the entire pipe production process, resulting in enhanced quality, durability, and efficiency.

As the demand for reliable and long-lasting infrastructure continues to grow, embracing innovative materials such as fibre reinforced concrete becomes essential. Investing in FRC technology is not just a short-term solution, but a step towards a more sustainable and efficient construction industry. By prioritizing these advancements, engineers and manufacturers can ensure that the pipes produced meet the rigorous standards required for modern infrastructure, paving the way for durable installations that withstand the test of time.

-

Custom Domestic Hot Water Heat Exchangers Efficient & Durable

NewsMay.24,2025

-

Cast Iron vs. Ductile Iron Differences, Uses & Benefits

NewsMay.24,2025

-

Top Gas Fired Boiler Supplier High-Efficiency Solutions & OEM Support

NewsMay.23,2025

-

Marine Gear Box Casting Solutions Durable & Custom OEM/ODM

NewsMay.23,2025

-

Custom Cast Iron Pipe Mold Bottom Ring Durable & ODM Solutions

NewsMay.22,2025

-

Precision nvestment Casting Services – Custom & ODM Solutions

NewsMay.22,2025