Januari . 15, 2025 05:49 Back to list

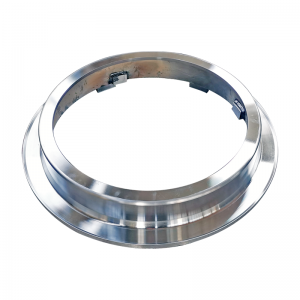

ductile cast iron manhole cover/ductile graphite manhole cover/ductile anti-theft manhole cover

Investment casting, also known as lost-wax casting, is a manufacturing process with a long history that combines artisan craftsmanship with advanced technological innovation. For companies seeking high-precision metal components, investment casting is a competitive choice that offers a unique set of advantages.

The reliability of investment casting is further underscored by stringent quality control measures. Leading suppliers implement rigorous testing protocols, such as radiographic, ultrasonic, and surface integrity inspections, to verify that each part meets the highest industry standards. These checks not only ensure product performance but also build trust with customers who rely on the integrity of each component for critical applications, such as in the aerospace or defense sectors. When considering a manufacturer for investment casting, it is essential to choose a partner with proven experience and a commitment to quality. Look for certifications and standards that demonstrate authority and credibility in the field, such as ISO certification or compliance with industry-specific standards. An experienced supplier will possess the necessary expertise to navigate the complexities of the casting process while offering advisement on material selection and design optimization. Trustworthiness in investment casting is paramount, particularly when components are destined for applications where failure is not an option. Manufacturers with a long-standing reputation for reliability and quality provide the confidence necessary for critical manufacturing decisions. Strong partnerships are built on a foundation of mutual trust and a shared commitment to excellence, ensuring that the cast components will perform reliably over their intended lifespan. In conclusion, investment casting stands as a blend of art and engineering, offering unmatched precision and versatility. Its benefits of material efficiency, cost-effectiveness, and high-quality results make it a preferred choice for industries requiring complex and precise metal components. By partnering with a trusted, experienced foundry, companies can harness the full potential of investment casting, paving the way for innovative designs and enduring partnerships.

The reliability of investment casting is further underscored by stringent quality control measures. Leading suppliers implement rigorous testing protocols, such as radiographic, ultrasonic, and surface integrity inspections, to verify that each part meets the highest industry standards. These checks not only ensure product performance but also build trust with customers who rely on the integrity of each component for critical applications, such as in the aerospace or defense sectors. When considering a manufacturer for investment casting, it is essential to choose a partner with proven experience and a commitment to quality. Look for certifications and standards that demonstrate authority and credibility in the field, such as ISO certification or compliance with industry-specific standards. An experienced supplier will possess the necessary expertise to navigate the complexities of the casting process while offering advisement on material selection and design optimization. Trustworthiness in investment casting is paramount, particularly when components are destined for applications where failure is not an option. Manufacturers with a long-standing reputation for reliability and quality provide the confidence necessary for critical manufacturing decisions. Strong partnerships are built on a foundation of mutual trust and a shared commitment to excellence, ensuring that the cast components will perform reliably over their intended lifespan. In conclusion, investment casting stands as a blend of art and engineering, offering unmatched precision and versatility. Its benefits of material efficiency, cost-effectiveness, and high-quality results make it a preferred choice for industries requiring complex and precise metal components. By partnering with a trusted, experienced foundry, companies can harness the full potential of investment casting, paving the way for innovative designs and enduring partnerships.

Share

Pervious:

Next:

Latest news

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025