- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Januari . 20, 2025 04:58 Back to list

fully premixed cast silicon aluminum heat exchanger for commercial boiler(L type)

Investing in machining technology is perhaps one of the smartest moves manufacturing businesses can make today. As the demand for precision-engineered products surges across industries such as automotive, aerospace, and medical devices, adopting cutting-edge machining technologies becomes essential. For businesses looking for a competitive edge, harnessing the full potential of investment in machining can lead to tangible improvements in productivity, product quality, and profitability.

Moreover, ongoing training and development programs for employees ensure that they remain proficient with the latest technological advancements. Constantly upgrading workforce skills not only boosts productivity but also fosters innovation as staff are empowered to experiment with advanced features and techniques. This culture of continuous learning and adaptation is vital for businesses intent on maintaining their authoritative stance in the market. Building authority in this sector also involves nurturing strong partnerships with equipment suppliers and technology providers. These relationships facilitate access to cutting-edge developments and the best technical support, thereby enhancing a company’s capability to respond swiftly to industry changes or customer demands. Furthermore, collaboration with research institutions can be advantageous in pioneering new machining methods or materials, further establishing a company’s role as an industry leader. Trustworthiness in the sphere of machining is cultivated through consistent quality delivery and adherence to stringent manufacturing standards. Quality certifications, like ISO 9001, validate a company’s commitment to excellence and reliability, assuring clients of superior product performance. By consistently meeting or surpassing these quality thresholds, businesses solidify their reputation, fostering long-term customer relationships built on trust. Real-world implementation of efficient machining investment practices can be observed in case studies of companies that have adopted digital twins and IoT-enabled machines, which allow real-time monitoring and predictive maintenance. This ability to foresee machine downtimes and proactively resolve them before they impact production showcases an intense reliability factor, saving both time and money while securing customer satisfaction. In conclusion, investment with machining technology should be viewed as an integral component of a company’s growth strategy. The measurable returns include enhanced production capabilities, reduced costs, superior product quality, and increased market competitiveness. When approached with expertise and a commitment to quality, investment in machining opens avenues for superior market domination and a reinforced reputation as an industry pacesetter. Companies that embrace these technological advancements now are not just preparing for the challenges of today but are also future-proofing their operations for the innovations of tomorrow.

Moreover, ongoing training and development programs for employees ensure that they remain proficient with the latest technological advancements. Constantly upgrading workforce skills not only boosts productivity but also fosters innovation as staff are empowered to experiment with advanced features and techniques. This culture of continuous learning and adaptation is vital for businesses intent on maintaining their authoritative stance in the market. Building authority in this sector also involves nurturing strong partnerships with equipment suppliers and technology providers. These relationships facilitate access to cutting-edge developments and the best technical support, thereby enhancing a company’s capability to respond swiftly to industry changes or customer demands. Furthermore, collaboration with research institutions can be advantageous in pioneering new machining methods or materials, further establishing a company’s role as an industry leader. Trustworthiness in the sphere of machining is cultivated through consistent quality delivery and adherence to stringent manufacturing standards. Quality certifications, like ISO 9001, validate a company’s commitment to excellence and reliability, assuring clients of superior product performance. By consistently meeting or surpassing these quality thresholds, businesses solidify their reputation, fostering long-term customer relationships built on trust. Real-world implementation of efficient machining investment practices can be observed in case studies of companies that have adopted digital twins and IoT-enabled machines, which allow real-time monitoring and predictive maintenance. This ability to foresee machine downtimes and proactively resolve them before they impact production showcases an intense reliability factor, saving both time and money while securing customer satisfaction. In conclusion, investment with machining technology should be viewed as an integral component of a company’s growth strategy. The measurable returns include enhanced production capabilities, reduced costs, superior product quality, and increased market competitiveness. When approached with expertise and a commitment to quality, investment in machining opens avenues for superior market domination and a reinforced reputation as an industry pacesetter. Companies that embrace these technological advancements now are not just preparing for the challenges of today but are also future-proofing their operations for the innovations of tomorrow.

Share

Pervious:

Next:

Latest news

-

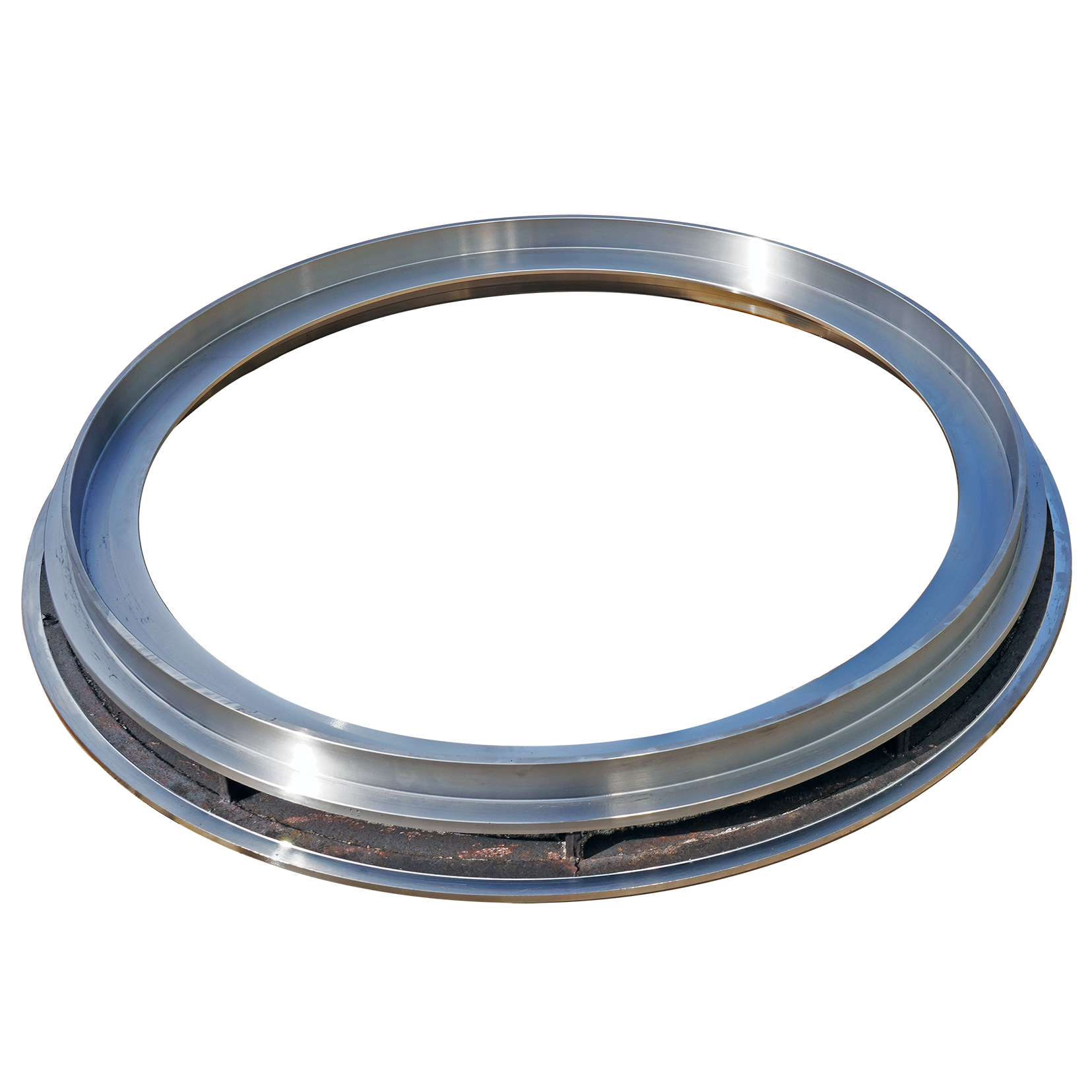

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025