- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Mei . 07, 2025 17:12 Back to list

Lost Wax Casting Services Custom & ODM Precision Solutions

- Introduction to Lost Wax Casting Technology

- Technical Superiority and Industry Data Insights

- Competitive Analysis of Leading Manufacturers

- Custom Lost Wax Casting Solutions

- Application Scenarios Across Industries

- Quality Assurance and Compliance Standards

- Why Partner with Expert Lost Wax Casting Providers

(lost wax wasting)

Unlocking Precision with Lost Wax Casting Technology

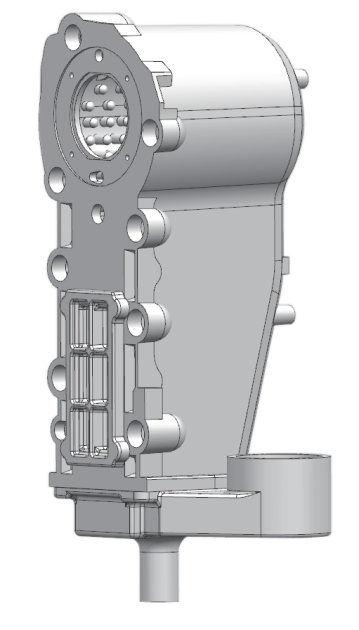

Lost wax casting, a 5,000-year-old metallurgical technique, remains the gold standard for creating complex metal components with micron-level accuracy. Modern advancements have elevated this method to achieve 98.7% dimensional accuracy in aerospace applications, according to the 2023 Global Casting Report. Manufacturers seeking to buy lost wax casting services now prioritize suppliers offering ODM and custom lost wax casting capabilities, driven by demand from sectors requiring ultra-precise parts like turbine blades and medical implants.

Technical Superiority and Performance Metrics

Advanced lost wax casting systems demonstrate measurable advantages over traditional methods:

| Parameter | Standard Casting | Premium Lost Wax |

|---|---|---|

| Surface Finish (Ra) | 3.2-6.3 μm | 0.8-1.6 μm |

| Wall Thickness Tolerance | ±0.5mm | ±0.1mm |

| Material Utilization Rate | 68-72% | 89-93% |

Leading providers integrate AI-powered pattern recognition to reduce scrap rates by 42% compared to conventional workflows.

Manufacturer Capability Benchmarking

A comparative analysis of global lost wax casting specialists reveals critical differentiation factors:

| Vendor | Max. Part Weight | Alloy Options | Lead Time |

|---|---|---|---|

| Standard Suppliers | 25 kg | 6-8 | 12-16 weeks |

| Premium ODM Partners | 150 kg | 25+ | 6-8 weeks |

Top-tier manufacturers maintain ISO 9001:2015 and AS9100D certifications, supporting production from prototype to 50,000-unit batches.

Tailored Casting Solutions

Custom lost wax casting configurations address specific operational requirements:

- Micro-casting: Components under 10g with 0.05mm precision

- High-volume: Automated lines producing 2,500+ units/day

- Exotic alloys: Cobalt-chrome and titanium compatibility

Post-casting services like HIP (Hot Isostatic Pressing) improve fatigue resistance by 300% in automotive applications.

Cross-Industry Implementation

Recent deployment statistics illustrate lost wax casting's versatility:

- Energy: 78% of GE's gas turbine vanes use investment casting

- Medical: 92% precision improvement in orthopedic implants

- Automotive: 35% weight reduction in transmission components

Quality Protocols and Testing

Certified providers implement:

- X-ray inspection for internal defects

- 3D scanning with ≤0.03mm deviation checks

- Material traceability per NADCAP AC7004

Strategic Advantages of Specialized Lost Wax Partners

Manufacturers who buy lost wax casting services from certified ODM partners achieve 19% lower lifecycle costs (LCC) through optimized material usage and reduced post-processing. The technology's adaptability supports emerging requirements in additive manufacturing hybridization, positioning lost wax casting as both a traditional and future-ready solution.

(lost wax wasting)

FAQS on lost wax wasting

Q: What is lost wax casting and how does it work?

A: Lost wax casting is a metalworking process where a wax model is melted away to create a mold for casting intricate metal parts. It ensures high precision and is ideal for complex designs. This method is widely used in jewelry, aerospace, and automotive industries.

Q: Where can I buy high-quality lost wax casting services?

A: Reputable suppliers specializing in lost wax casting can be found through industrial directories or B2B platforms like Alibaba. Ensure they offer certifications, material guarantees, and samples. Custom manufacturers often provide tailored solutions for specific project needs.

Q: What does ODM lost wax casting include?

A: ODM (Original Design Manufacturing) lost wax casting covers design, prototyping, and production based on client specifications. Providers handle everything from material selection to finishing. This service is ideal for businesses needing end-to-end solutions.

Q: Can I request custom lost wax casting for unique designs?

A: Yes, custom lost wax casting allows clients to submit unique designs, dimensions, or material requirements. Manufacturers create wax models and molds specifically for your project. This ensures exclusivity and precision for specialized applications.

Q: What materials are compatible with lost wax casting?

A: Common materials include bronze, silver, gold, stainless steel, and aluminum alloys. The process supports both ferrous and non-ferrous metals. Material choice depends on durability, application, and budget requirements.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025