- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oktoba . 15, 2024 04:32 Back to list

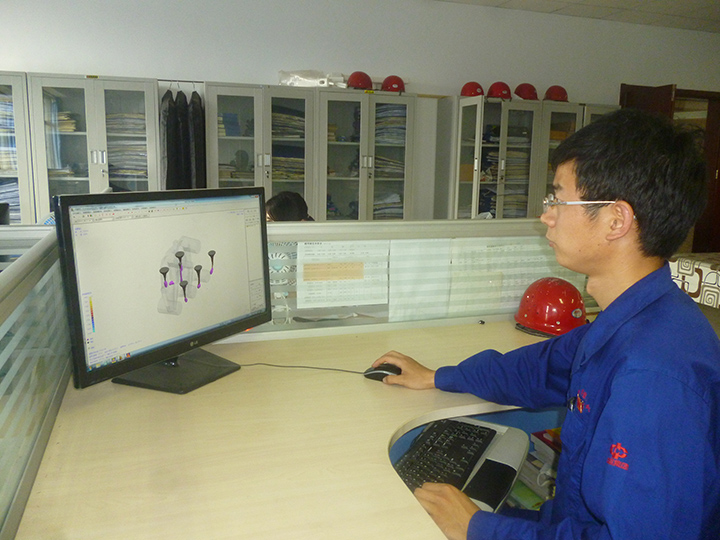

Innovative Techniques in ODM Aluminum Casting for Enhanced Product Performance and Durability

Understanding ODM Aluminum Casting

Aluminum casting is a vital manufacturing process that plays a crucial role in various industries, including automotive, aerospace, and machinery. Among the several casting methods available, Original Design Manufacturer (ODM) aluminum casting stands out due to its unique alignment of design and production capabilities tailored to meet the specific needs of clients. In this article, we will explore the concept of ODM aluminum casting, its advantages, applications, and the factors to consider when choosing an ODM partner.

What is ODM Aluminum Casting?

Original Design Manufacturing (ODM) refers to the practice where manufacturers design and produce products based on the specifications provided by another company, often a brand that markets the product under its name. When it comes to aluminum casting, ODM not only involves the physical production of aluminum components but also encompasses the design phase. This means that ODM partners work closely with their clients, offering expertise in product design, material selection, and the best casting techniques to meet the desired specifications.

Aluminum casting itself encompasses several methods such as sand casting, die casting, investment casting, and gravity casting. Each technique has its pros and cons and is selected based on the final product's requirements, including complexity, volume, and tolerances.

Advantages of ODM Aluminum Casting

1. Customization One of the primary benefits of ODM aluminum casting is the high level of customization it offers. Clients can specify their design needs, and ODM manufacturers have the expertise to bring those designs to life. This ensures that the final product aligns closely with the brand's vision and requirements.

2. Time Efficiency By working with an ODM provider, companies can significantly reduce the time to market. Since the ODM partner handles both design and production, there is less back-and-forth between different parties, streamlining the development process.

3. Cost-Effectiveness ODM aluminum casting can prove more economical compared to traditional manufacturing models. The ODM partner can optimize the design for manufacturability, which often leads to reduced waste and lower production costs. This cost efficiency is particularly beneficial for businesses looking to produce large volumes.

4. Expertise and Innovation ODM manufacturers are typically experts in aluminum casting processes, materials, and design considerations. They can offer valuable insights into the latest industry trends, technologies, and best practices, helping clients innovate their product offerings.

odm aluminum casting

5. Quality Control Working with an ODM provider allows for more controlled quality assurance processes. These manufacturers often have established quality control systems and certifications, ensuring that the final products meet required industry standards.

Applications of ODM Aluminum Casting

The applications of ODM aluminum casting are vast and varied. In the automotive industry, it is often used for producing engine components, transmission housings, and structural parts. In aerospace, aluminum castings are utilized for creating lightweight yet strong components that enhance fuel efficiency. Machinery manufacturers also benefit from ODM aluminum castings for creating intricate parts that require precise dimensions and tolerances.

Additionally, the consumer goods sector is seeing an increase in the use of ODM aluminum casting for products such as kitchen appliances, furniture fittings, and sporting equipment. The versatility and durability of aluminum make it an ideal material choice for both functional and aesthetic components.

Choosing the Right ODM Partner

When selecting an ODM partner for aluminum casting, several factors should be considered. First, evaluate the manufacturer's experience and expertise in aluminum casting and related industries. Ensure they have a proven track record of delivering quality products that meet industry standards.

Second, assess their capabilities in terms of design and engineering. A strong ODM partner should be able to assist with the entire design phase, offering suggestions to optimize both functionality and manufacturability.

Finally, consider their production capacity and technology. The right partner should possess advanced casting techniques and machinery to handle both small and large production runs efficiently.

Conclusion

ODM aluminum casting offers a unique blend of design and manufacturing capabilities, providing businesses with tailored solutions to their specific needs. With an emphasis on customization, cost-effectiveness, and quality, ODM casting has become an integral part of modern manufacturing across numerous industries. As businesses continue to seek innovative ways to enhance their product offerings, the role of ODM partners in aluminum casting will undoubtedly grow, shaping the future landscape of the industry.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025