- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Desemba . 11, 2024 10:13 Back to list

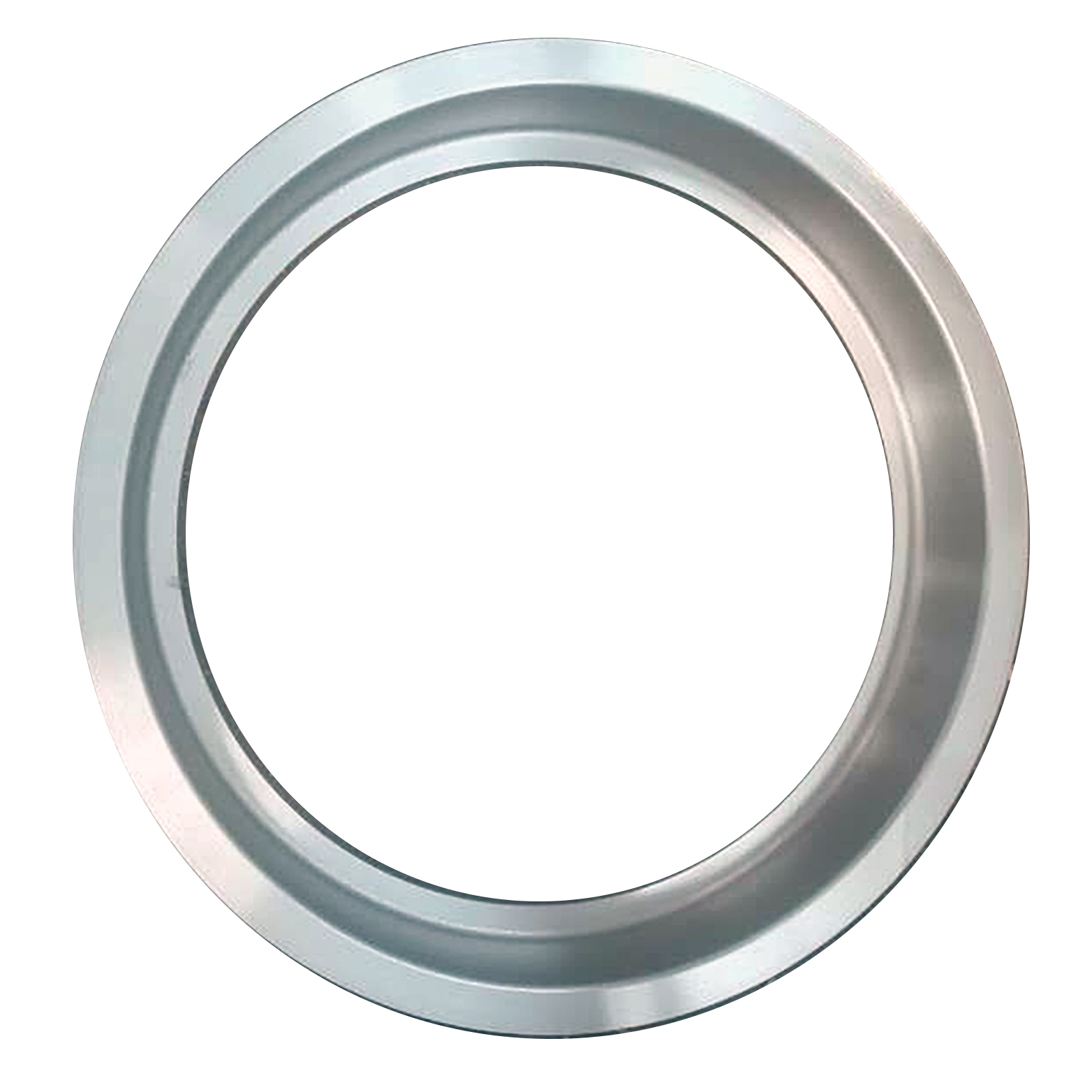

suppliers of concrete pipe moulds and bottom rings for construction industry

The Importance of Quality in Selecting Concrete Pipe Mould Bottom Ring Suppliers

When it comes to constructing infrastructure, concrete pipes play a vital role in various applications, ranging from drainage systems to sewage management. One critical component in the production of these pipes is the mould used to cast them, particularly the bottom ring of the mould. As such, selecting the right suppliers for concrete pipe mould bottom rings is crucial for ensuring high-quality outcomes. In this article, we will explore the key considerations in choosing reliable suppliers, the benefits of using high-quality moulds, and some industry trends that may influence the market in the future.

Understanding the Basics of Concrete Pipe Moulds

Concrete pipe moulds are essential for achieving the desired shape and dimensions of the pipes being produced. Among these moulds, the bottom ring plays a pivotal role, as it establishes the stability and structural integrity of the pipe during the curing process. A well-designed and constructed bottom ring can significantly impact the quality of the finished product, making it crucial to source these components from reputable suppliers.

Key Considerations in Supplier Selection

1. Quality of Materials The durability and longevity of concrete pipe moulds largely depend on the materials used in their construction. High-quality steel or reinforced materials should be prioritized, as these can withstand the pressures of concrete pouring and maintain their shape during repeated use.

2. Fabrication Techniques Modern fabrication techniques such as precision machining and automated welding can ensure consistent quality and dimensional accuracy. Suppliers that employ advanced manufacturing processes are often able to deliver superior moulds that meet stringent industry standards.

3. Customization Options Different construction projects often require specific dimensions and designs for concrete pipes. The ability to customize moulds can add significant value. Therefore, it is essential to choose suppliers who can accommodate unique specifications.

4. Reputation and Experience A supplier's track record in the industry can provide insights into their reliability and quality. Companies that have been in business for several years with positive customer feedback are generally more trustworthy.

5. Technical Support and After-Sales Service A supplier that offers comprehensive support—such as installation guidance, maintenance tips, and replacement parts—will enhance your operational efficiency. This type of partner can help avoid potential issues and ensure a smooth production process.

Benefits of High-Quality Concrete Pipe Mould Bottom Rings

src concrete pipe mould bottom ring suppliers

Investing in high-quality bottom rings for concrete pipe moulds comes with numerous benefits

- Enhanced Durability Quality materials and solid construction lead to longer-lasting moulds that can endure frequent use without deteriorating.

- Improved Quality of Pipes High-quality moulds produce more accurate and consistent pipe dimensions, which can reduce waste and ensure better fitting in construction.

- Cost Efficiency While the initial investment in superior moulds may be higher, the long-term savings from reduced maintenance and increased durability make them a cost-effective choice.

- Faster Production Times Reliable moulds that perform consistently can streamline the production process, allowing for quicker turnaround times on projects.

Industry Trends Influencing Supplier Choices

The concrete pipe production industry is evolving, with trends influenced by technology and sustainability. The rise of automated manufacturing and digital design tools has improved the precision of moulds, leading to better overall product quality. Furthermore, there is a growing emphasis on environmentally friendly practices, including the use of recycled materials in mould production.

Another trend is the increasing demand for customized solutions tailored to specific project needs. This has prompted suppliers to offer more flexible options for clients, adapting to the rapidly changing requirements of the construction sector.

Conclusion

Selecting the right supplier for concrete pipe mould bottom rings is a crucial consideration for construction companies. By focusing on quality, reputation, and the ability to provide customization and support, businesses can ensure that they get the best possible products for their projects. With ongoing advancements in manufacturing techniques and a stronger focus on sustainability, the concrete pipe mould industry is poised for growth. By partnering with reliable suppliers, construction firms can improve their efficiency, reduce costs, and ultimately contribute to the development of robust infrastructure.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025