- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

அக் . 30, 2024 22:52 Back to list

china cast silicon aluminum heat exchanger for commercial heating boiler

The Role of Cast Silicon Aluminum Heat Exchangers in Commercial Heating Boilers

In the realm of commercial heating solutions, the efficiency and reliability of heating systems are paramount. With the increasing demands for energy efficiency and performance, cast silicon aluminum heat exchangers have emerged as a viable option for heating boilers, particularly in China. These heat exchangers play a crucial role in enhancing the thermal performance while also addressing the challenges posed by traditional materials.

Cast silicon aluminum alloys are specially designed to withstand high temperatures and corrosive environments, making them well-suited for heat exchange applications in commercial heating boilers. The unique properties of these materials, including their lightweight nature, high thermal conductivity, and resistance to oxidation, contribute significantly to the overall efficiency of the heating system. Unlike conventional metal heat exchangers, cast silicon aluminum offers improved durability and performance due to its exceptional resistance to thermal fatigue and wear.

One of the primary advantages of using cast silicon aluminum heat exchangers is their ability to optimize the heat transfer process. The design of these heat exchangers allows for a larger surface area, which facilitates better heat absorption and distribution. This improvement in heat transfer efficiency leads to reduced energy consumption, ultimately providing cost savings for commercial boiler operators. Furthermore, the lightweight nature of these materials simplifies the installation process, allowing for easier handling and reduced structural support requirements.

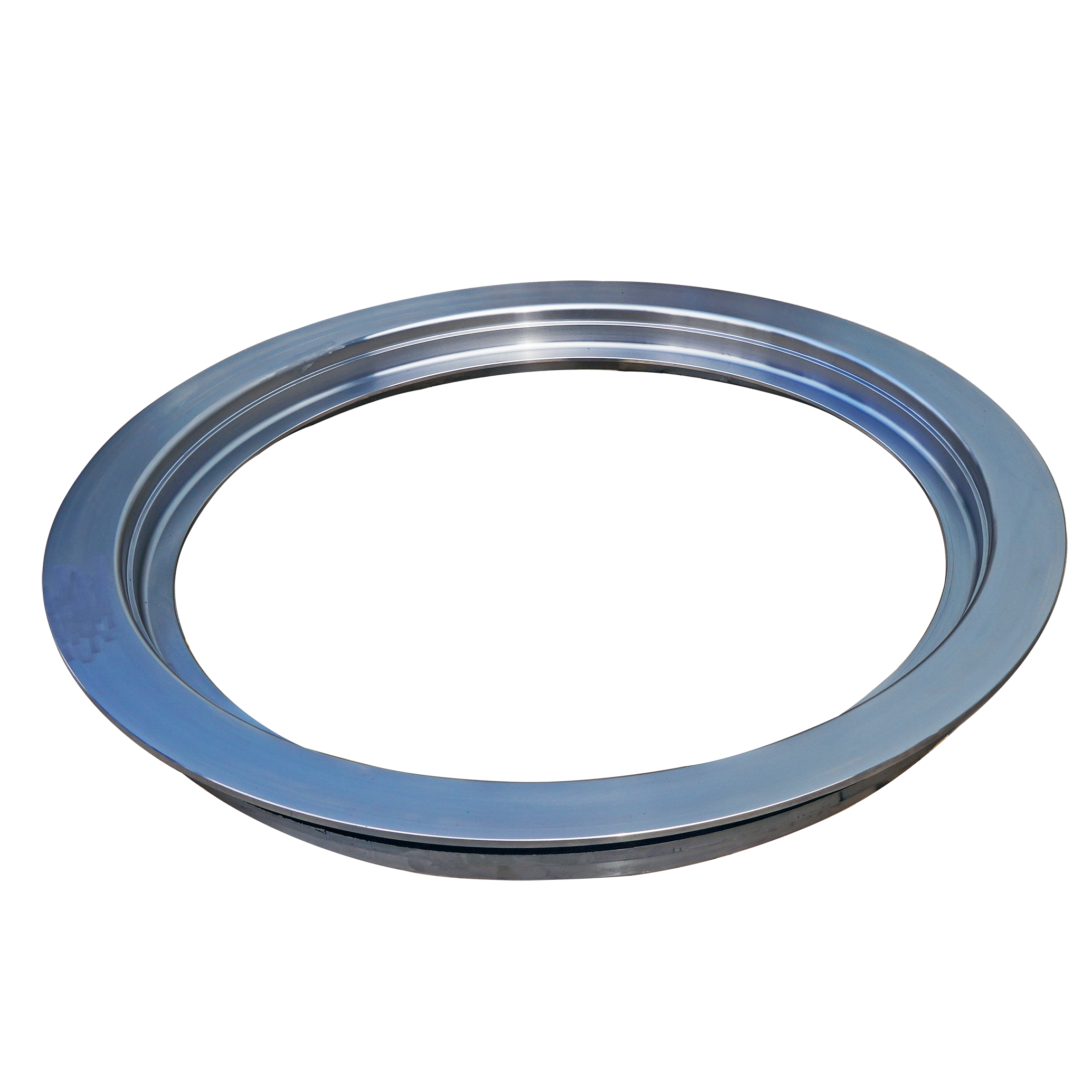

china cast silicon aluminum heat exchanger for commercial heating boiler

Apart from their performance benefits, environmental considerations are also driving the adoption of cast silicon aluminum heat exchangers. As industries worldwide strive to minimize their carbon footprint and comply with stringent emission regulations, the use of energy-efficient heating systems becomes essential. By minimizing energy loss and maximizing the heat recovery process, these heat exchangers contribute to reduced greenhouse gas emissions, aligning with global sustainability goals.

The Chinese market, with its rapid industrial growth, presents a significant opportunity for the development and proliferation of cast silicon aluminum heat exchangers in the heating boiler industry. Manufacturers in China are increasingly investing in advanced casting technologies and processes to enhance the quality and performance of these heat exchangers. This shift not only bolsters the domestic market but also positions China as a competitive player in the global arena.

In conclusion, cast silicon aluminum heat exchangers are revolutionizing commercial heating boiler systems, particularly in China. Their unique properties, optimized heat transfer capabilities, and alignment with environmental standards make them a superior choice for modern heating applications. As manufacturers continue to innovate and improve these materials, the future looks promising for energy-efficient heating solutions that cater to the growing demands of the commercial sector. The shift towards cast silicon aluminum heat exchangers signifies a progressive step towards sustainable and efficient heating practices, ensuring reliability and performance for years to come.

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025