- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

నవం . 12, 2024 23:13 Back to list

aluminium cast alloy

The Significance of Aluminium Cast Alloys in Modern Manufacturing

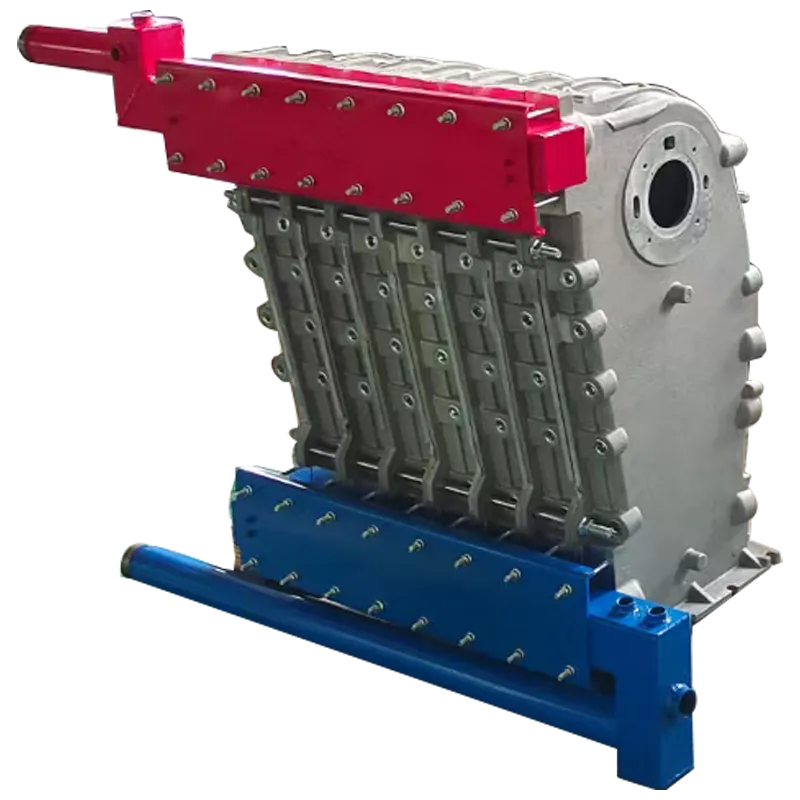

Aluminium cast alloys play a vital role in various industries due to their unique properties, including lightweight, corrosion resistance, and excellent machinability. These alloys are primarily used in applications where reducing weight without compromising strength is critical, making them a preferred choice in aerospace, automotive, and consumer goods manufacturing.

One of the most significant advantages of aluminium cast alloys is their lightweight nature. Compared to traditional materials like steel, aluminium alloys can significantly reduce the overall weight of a product. In the transportation sector, for instance, lighter vehicles improve fuel efficiency, which is crucial for meeting modern environmental standards. This has led to increased adoption of aluminium in vehicle construction, including engine blocks, transmission cases, and structural components.

Aluminium cast alloys are categorized by their alloying elements, which typically include copper, magnesium, silicon, and zinc. Each alloy has distinct properties, tailored to specific applications. For example, the A356 alloy, which contains silicon and magnesium, offers excellent castability, high strength, and good corrosion resistance, making it ideal for automotive and aerospace components. Meanwhile, A380 is known for its outstanding fluidity and is often used in die casting applications requiring intricate shapes.

aluminium cast alloy

The casting process itself significantly influences the performance characteristics of aluminium alloys. Common techniques include sand casting, die casting, and investment casting. Sand casting is versatile and cost-effective for low-volume production, while die casting is ideal for high-volume manufacturing due to its rapid cycle times and ability to produce complex shapes with tight tolerances. Investment casting, on the other hand, is often employed for intricate designs and high-precision applications.

In addition to their mechanical properties, aluminium cast alloys are also celebrated for their excellent corrosion resistance, which is enhanced by the formation of a protective oxide layer

. This characteristic is particularly valuable in outdoor applications and environments where components are exposed to harsh elements. The durability of these alloys extends the lifespan of products and reduces maintenance costs, proving beneficial for manufacturers and consumers alike.As technology advances, the development of new aluminium cast alloys continues to evolve. Researchers are focused on enhancing the performance characteristics of these materials through innovative alloy compositions and improved casting techniques. This ongoing development is crucial in meeting the demands of modern engineering, where strength-to-weight ratios and sustainability are paramount.

In conclusion, aluminium cast alloys are integral to modern manufacturing, offering a combination of lightweight, strength, and durability. Their applications span numerous industries, and their significance is only set to grow as technology and manufacturing processes advance. As we look to the future, continued research and development in this field will ensure that aluminium cast alloys remain at the forefront of material science.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025