- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

జన . 09, 2025 10:36 Back to list

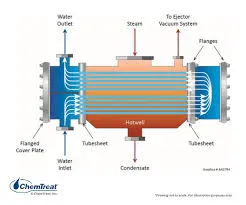

FULLY-PREMIXED LOW-NITROGEN CONDENSING BOILER FOR COMMERCIAL PURPOSE

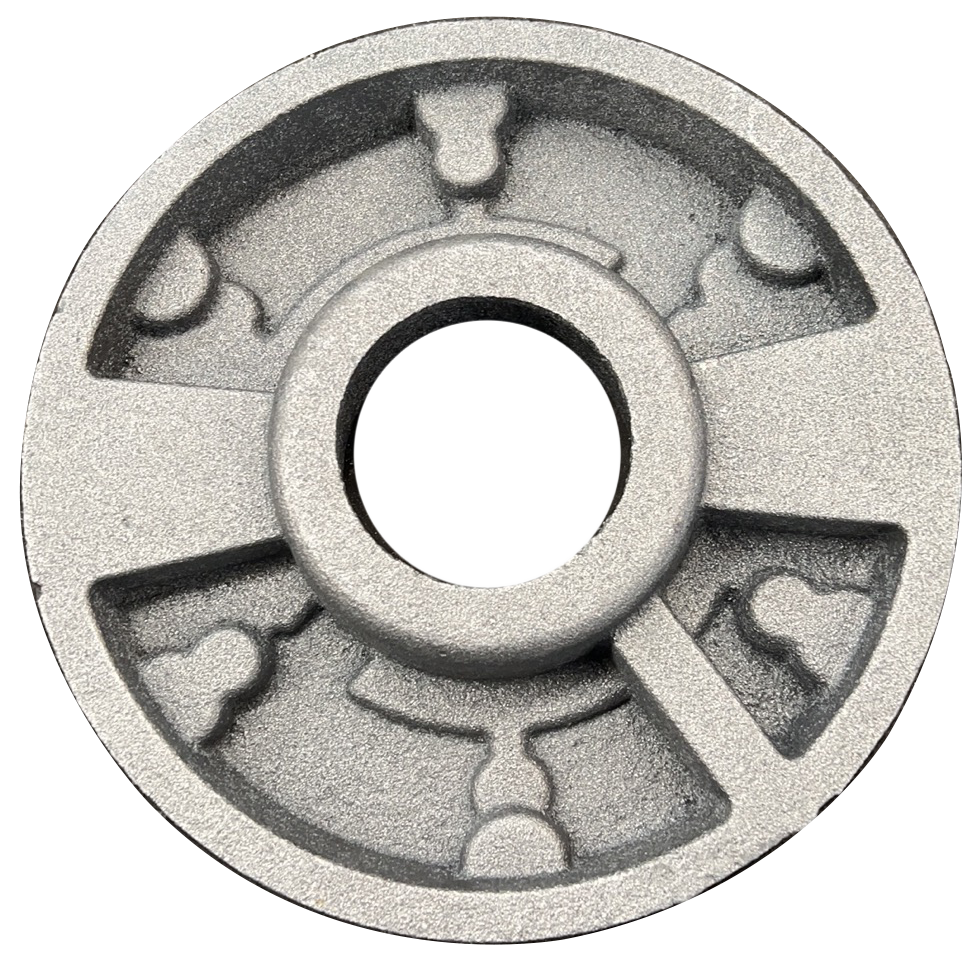

Concrete pipe mold pallets play a crucial role in the production of high-quality concrete pipes, which are essential for various infrastructure projects such as sewage systems, stormwater drainage, and culverts. A deep dive into the operational excellence and quality assurance of these pallets reveals their indispensable nature in ensuring the longevity and structural integrity of concrete pipes.

Authoritativeness in the concrete pipe manufacturing industry often correlates with the adoption of the latest technological innovations. Companies that lead in the production of concrete pipe mold pallets often collaborate with research institutions to innovate new materials and designs. For instance, some manufacturers are exploring composite materials that offer enhanced resistance to corrosion and wear, thereby increasing the durability of the pallets. This type of innovation not only sets a high industry standard but also builds trust among clients who seek reliable suppliers for their construction needs. Trustworthiness in using concrete pipe mold pallets emanates from consistent quality management practices. Manufacturers who adhere to ISO quality standards or similar certifications provide assurance that their products are reliable and safe. Regular audits and quality checks throughout the production process are necessary to maintain these standards. Companies often provide detailed documentation of these procedures, which enhances transparency and builds trust with clients. This trust is further solidified through customer reviews and testimonials that reflect real-world satisfaction and long-term performance of the pallets in diverse conditions. In conclusion, concrete pipe mold pallets are an essential component of the concrete pipe production process, and their quality is critical to ensuring the effectiveness of infrastructure projects. Through dedicated experience, specialized expertise, authoritative industry practices, and proven trustworthiness in manufacturing, these tools contribute significantly to developing robust infrastructure systems worldwide. Conscientious selection and use of mold pallets not only enhance production efficiency but also lead to lasting benefits in construction projects.

Authoritativeness in the concrete pipe manufacturing industry often correlates with the adoption of the latest technological innovations. Companies that lead in the production of concrete pipe mold pallets often collaborate with research institutions to innovate new materials and designs. For instance, some manufacturers are exploring composite materials that offer enhanced resistance to corrosion and wear, thereby increasing the durability of the pallets. This type of innovation not only sets a high industry standard but also builds trust among clients who seek reliable suppliers for their construction needs. Trustworthiness in using concrete pipe mold pallets emanates from consistent quality management practices. Manufacturers who adhere to ISO quality standards or similar certifications provide assurance that their products are reliable and safe. Regular audits and quality checks throughout the production process are necessary to maintain these standards. Companies often provide detailed documentation of these procedures, which enhances transparency and builds trust with clients. This trust is further solidified through customer reviews and testimonials that reflect real-world satisfaction and long-term performance of the pallets in diverse conditions. In conclusion, concrete pipe mold pallets are an essential component of the concrete pipe production process, and their quality is critical to ensuring the effectiveness of infrastructure projects. Through dedicated experience, specialized expertise, authoritative industry practices, and proven trustworthiness in manufacturing, these tools contribute significantly to developing robust infrastructure systems worldwide. Conscientious selection and use of mold pallets not only enhance production efficiency but also lead to lasting benefits in construction projects.

Share

Pervious:

Latest news

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025