- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

నవం . 17, 2024 05:55 Back to list

sodium slicate sand casting manufacturer

Sodium Silicate Sand Casting An Overview

Sodium silicate sand casting is an innovative and efficient method used in the metal casting industry. This process utilizes sodium silicate as a binder, which combines with silica sand to create a strong and durable mold for casting various metal components. The unique properties of sodium silicate make it a preferred choice for manufacturers seeking both flexibility and precision in their casting processes.

Understanding the Process

At the heart of sodium silicate sand casting is the use of sodium silicate, often referred to as water glass. This compound, when mixed with sand, forms a paste that hardens when exposed to carbon dioxide (CO2) gas. The process begins with the aggregation of clean silica sand with sodium silicate and water, creating a mixture that can be molded into the desired shape. Once the sand mixture has been compacted into the mold, CO2 is introduced, causing the sodium silicate to cure and form a solid, rigid mold.

The simplicity and efficiency of this method offer distinct advantages. The molds produced from sodium silicate sand are not only lightweight but also possess excellent dimensional accuracy, making them ideal for high-precision applications. Additionally, the low moisture content in the mixture reduces the risk of defects during the casting process, ensuring a higher quality final product.

Advantages of Sodium Silicate Sand Casting

One of the primary benefits of sodium silicate sand casting is its versatility. The process is well-suited for a wide range of metals, including aluminum, iron, and steel. This flexibility enables manufacturers to cater to diverse client needs, from producing intricate small components to large, heavy parts.

Moreover, sodium silicate provides excellent thermal stability. Molds created from this method can withstand high temperatures, reducing the likelihood of deformation during the casting process. This property is particularly crucial in industries where precision and reliability are paramount, such as aerospace and automotive sectors.

sodium slicate sand casting manufacturer

Environmental considerations are also noteworthy. Sodium silicate is an inorganic binder that is non-toxic, making it a more environmentally friendly option compared to other traditional binding agents. Additionally, the process generates less waste and reduces the overall footprint of the casting operation.

Applications in Various Industries

The applications of sodium silicate sand casting extend across numerous industries. In the automotive sector, this method is used to produce engine blocks, cylinder heads, and various gearbox components. Due to its ability to create complex geometries, it is also popular in the production of intricate parts for machinery, pumps, and valves.

The aerospace industry benefits from sodium silicate sand casting through the manufacture of components that require exceptional strength and lightweight properties, such as brackets and housings. Furthermore, the capability to achieve tight tolerances means that parts can be produced with minimal machining, thereby reducing costs and lead times.

Choosing a Manufacturer

When it comes to finding a sodium silicate sand casting manufacturer, it is essential to consider several factors. Look for companies with a proven track record and experience in the industry. Their expertise will ensure that they can deliver high-quality products that meet specific client requirements. Additionally, assess their technological capabilities and quality control measures to ensure that they adhere to industry standards.

In conclusion, sodium silicate sand casting is an efficient and versatile method that offers significant advantages to manufacturers across multiple sectors. Its ability to produce precise and durable molds, coupled with environmental benefits, positions it as a leading choice in modern metal casting techniques. As industries continue to evolve, the demand for innovative casting solutions like sodium silicate sand casting will undoubtedly remain on the rise.

-

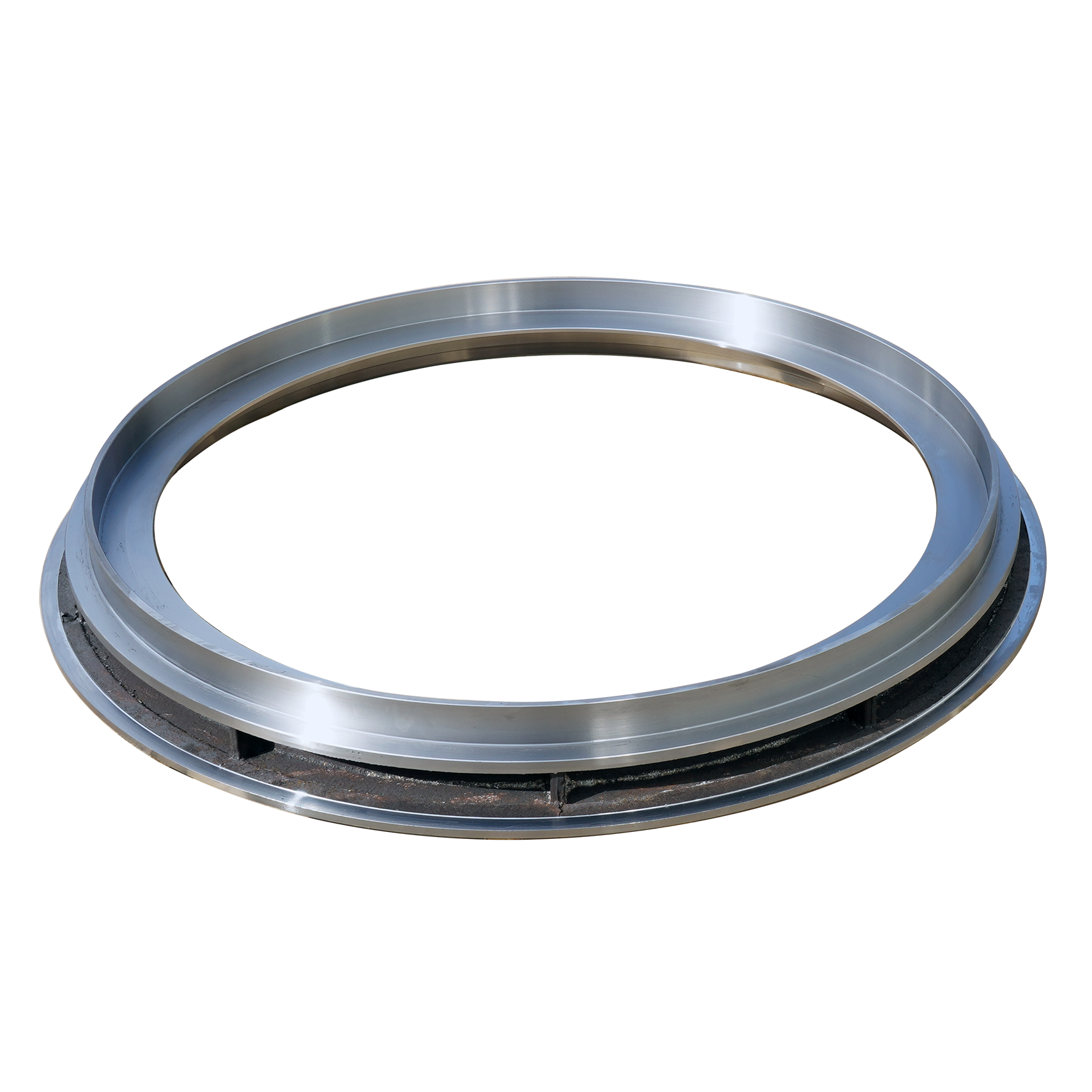

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025