- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 06, 2024 09:58 Back to list

Cast Silicon Aluminum Heat Exchanger Design for Efficient Commercial Hot Water Boilers

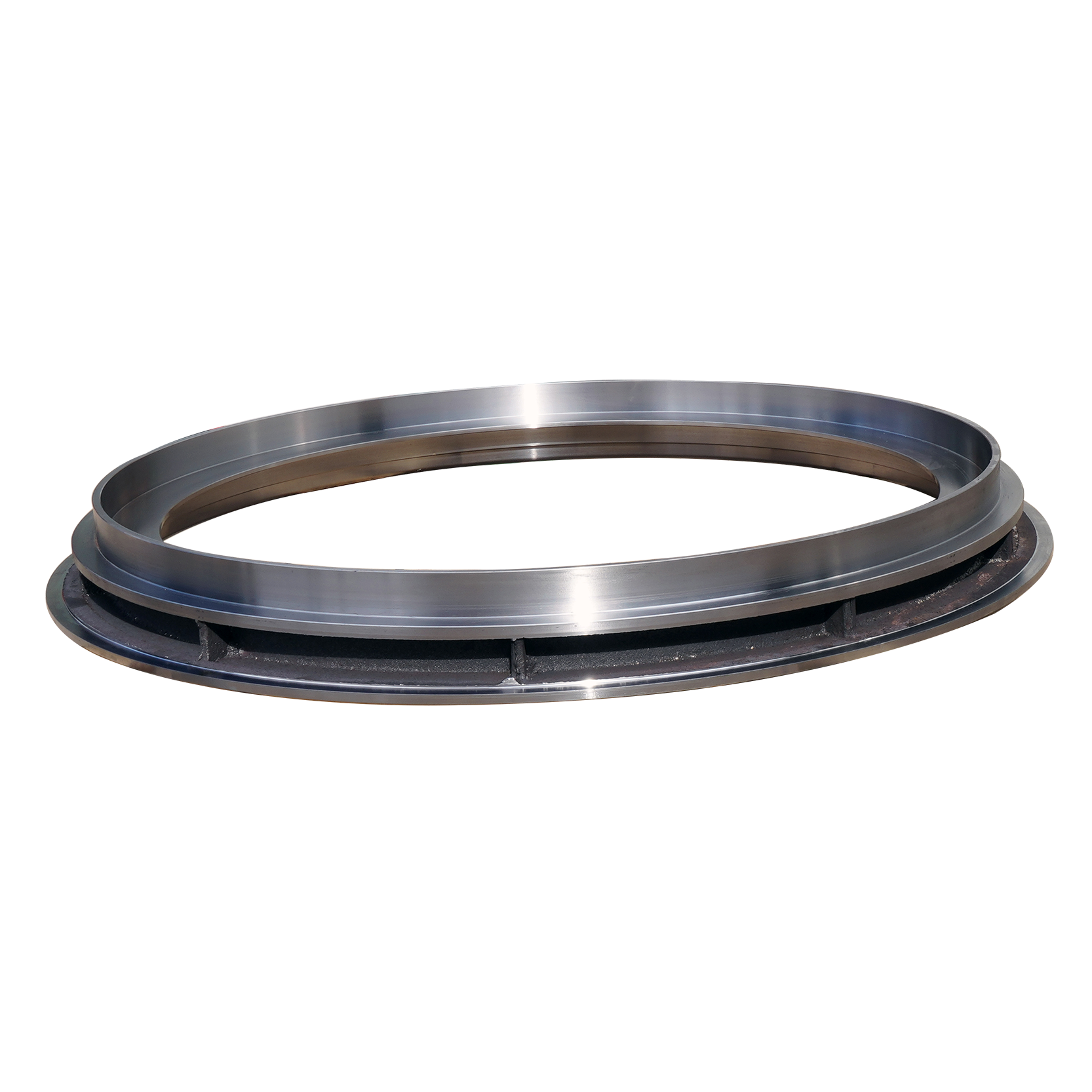

Cast Silicon Aluminum Heat Exchangers for Commercial Hot Water Boilers

In today's rapidly evolving industrial landscape, the demand for efficient and reliable heating solutions has never been higher. Among these solutions, cast silicon aluminum heat exchangers have emerged as a leading technology for commercial hot water boilers. This article explores the advantages of using cast silicon aluminum heat exchangers, their applications in commercial settings, and their role in enhancing energy efficiency and performance.

Understanding Cast Silicon Aluminum

Cast silicon aluminum is an alloy known for its favorable thermal properties, durability, and resistance to corrosion. This alloy is particularly effective in extreme temperature conditions, making it ideal for use in heat exchangers. The addition of silicon to aluminum enhances its castability, allowing for more complex shapes and efficient heat transfer surfaces that are essential for effective thermal management.

Advantages of Cast Silicon Aluminum Heat Exchangers

1. High Thermal Conductivity One of the primary benefits of using cast silicon aluminum is its superior thermal conductivity. This characteristic enables efficient heat transfer from the hot water to the heating medium, resulting in faster heating times and reduced energy consumption. In commercial settings, this efficiency can lead to significant cost savings.

2. Corrosion Resistance Commercial hot water boilers often operate in harsh environments, which can lead to corrosion of standard materials. Cast silicon aluminum provides excellent resistance to oxidation and corrosion, especially in high-temperature and high-humidity conditions. This durability ensures a longer lifespan for heat exchangers, reducing the need for frequent replacements and maintenance.

3. Lightweight Design The lightweight nature of cast silicon aluminum compared to traditional materials, such as stainless steel or copper, translates into easier installation and reduced transportation costs. For commercial facilities, this can mean lower installation costs and quicker project turnaround times.

4. Design Flexibility The casting process allows for intricate designs that can optimize the heat exchange surface area. This flexibility means that manufacturers can create heat exchangers specifically tailored to the unique requirements of various commercial boilers, enhancing performance and efficiency.

cast silicon aluminum heat exchanger for commercial hot water boiler

5. Environmental Benefits Energy-efficient hot water systems contribute positively to sustainability goals. Cast silicon aluminum heat exchangers can help commercial boilers meet stringent energy efficiency standards, ultimately reducing greenhouse gas emissions and energy consumption.

Applications in Commercial Hot Water Boilers

Cast silicon aluminum heat exchangers are predominantly used in a variety of commercial applications, including

- Hotels and Restaurants These facilities require large volumes of hot water for showers, dishwashing, and cooking. Efficient heat exchangers help maintain consistent water temperatures while minimizing energy usage.

- Industrial Facilities Industries that require hot water for processing, cleaning, or heating can benefit significantly from the efficiency gains provided by cast silicon aluminum heat exchangers. They can handle the rigorous demands of high-volume applications without compromising performance.

- Healthcare Institutions Hospitals and clinics need reliable and consistent hot water supplies, particularly for sanitation and patient care. The durability and efficiency of cast silicon aluminum heat exchangers make them an ideal choice for these critical applications.

Conclusion

As the drive for energy efficiency and sustainability continues to grow, cast silicon aluminum heat exchangers stand out as a superior choice for commercial hot water boilers. With their exceptional thermal properties, corrosion resistance, lightweight design, and environmental benefits, these heat exchangers are well-suited to meet the demands of diverse industries. By integrating this advanced technology into commercial heating systems, businesses can improve performance, reduce operational costs, and contribute to a greener future. The transition towards cast silicon aluminum technology signifies not only a step forward in boiler efficiency but also a commitment to sustainability in the commercial heating sector.

-

Ductile Iron Casting Solutions High-Strength & Corrosion-Resistant

NewsMay.13,2025

-

Custom Low Nitrogen Condensing Gas Boilers for Domestic Hot Water

NewsMay.13,2025

-

EN877 Grey Cast Iron Pipe Casting Custom Epoxy Coating Solutions

NewsMay.12,2025

-

Cast Silicon Aluminum Heat Exchanger for Commercial Boilers High Efficiency

NewsMay.12,2025

-

Custom Colloidal Silica Casting High-Precision & Durable Solutions

NewsMay.11,2025

-

Premium Metal Sand Casting Services Custom & ODM Solutions

NewsMay.11,2025