Over the past decade, there has been a significant demand surge in infrastructure, urban sewage, and water supply projects, fueling the need for advanced and durable concrete pipe molds and base components. According to the American Concrete Pipe Association, the global demand for reinforced concrete pipes (RCP) is expected to grow by 5.2% annually through 2027 (GrandView Research).

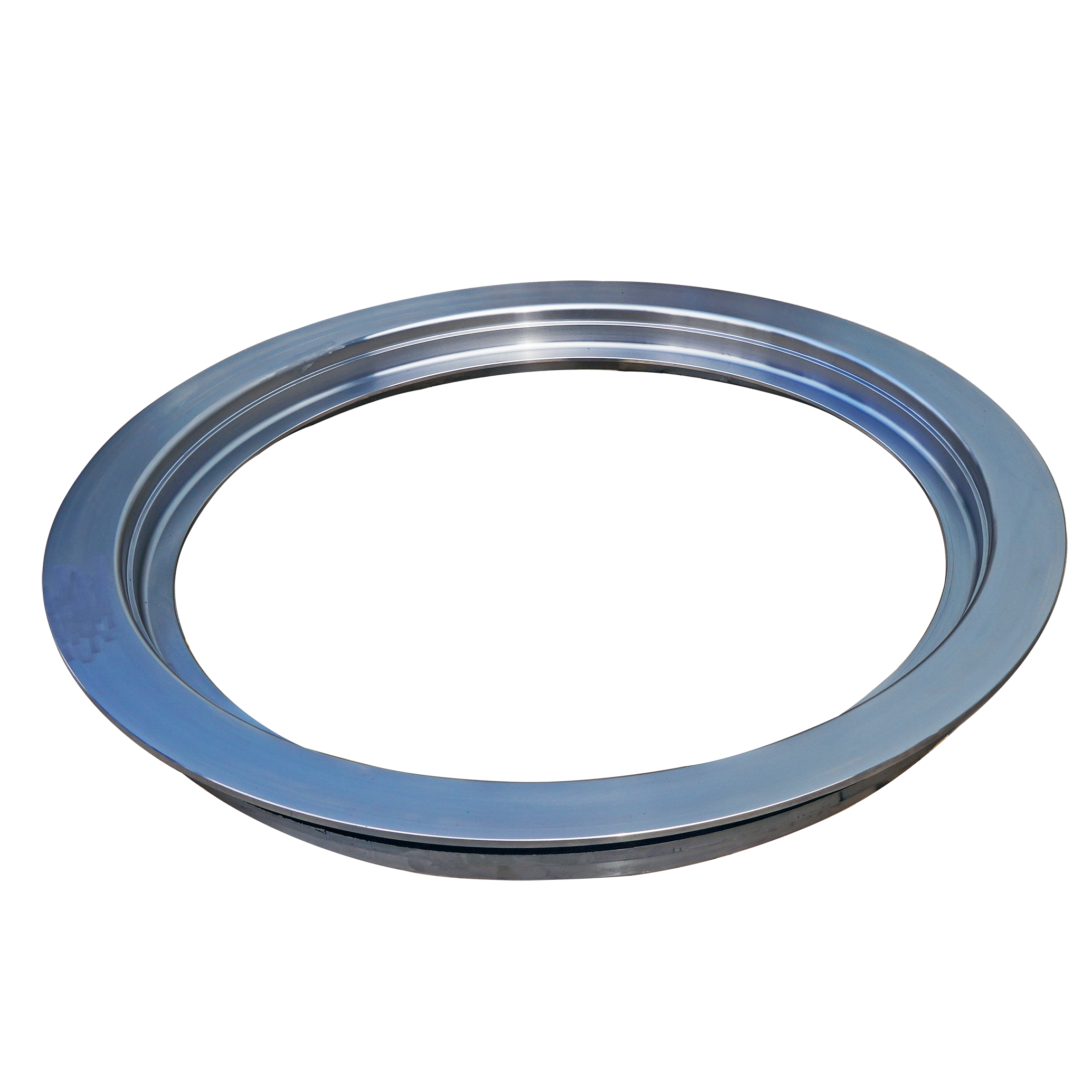

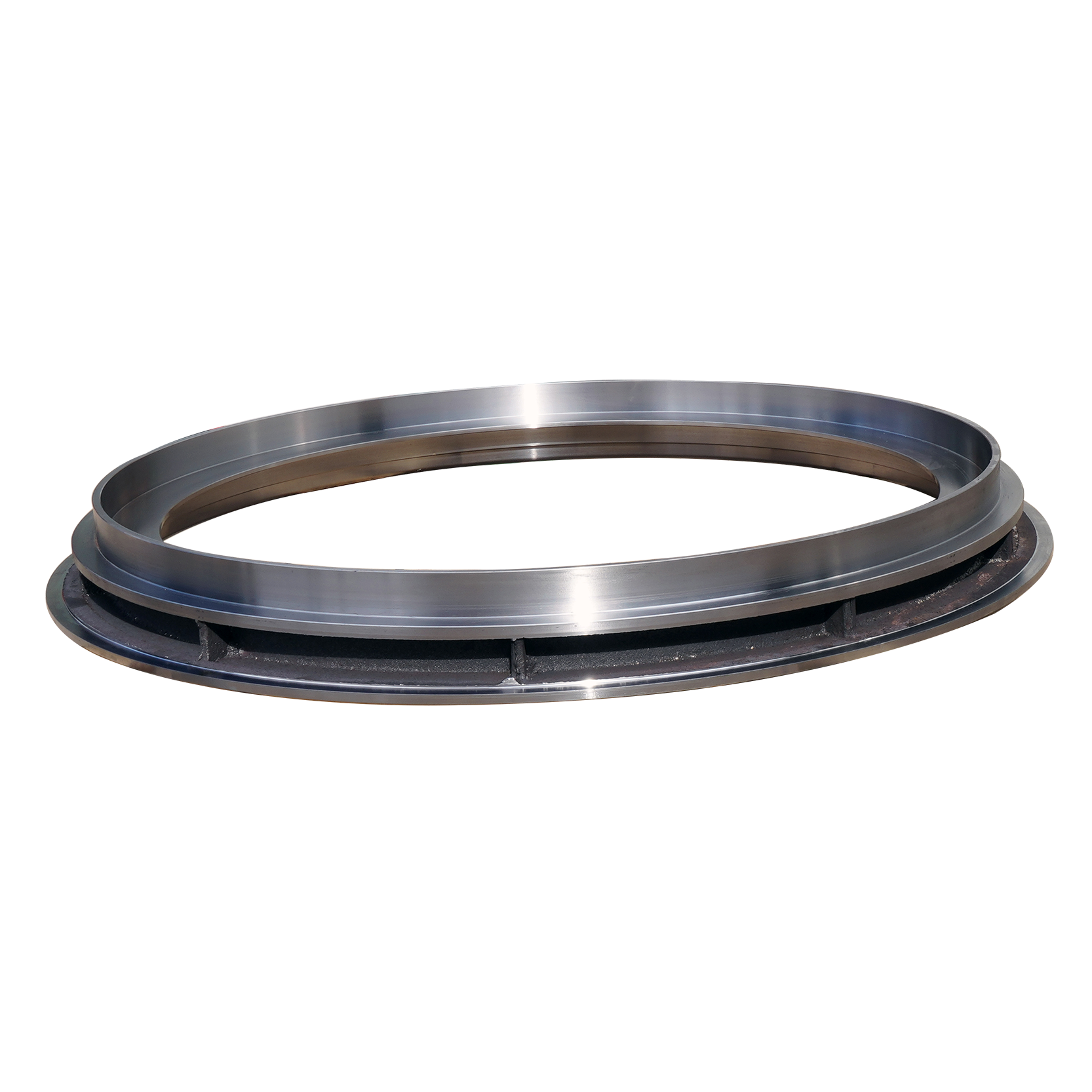

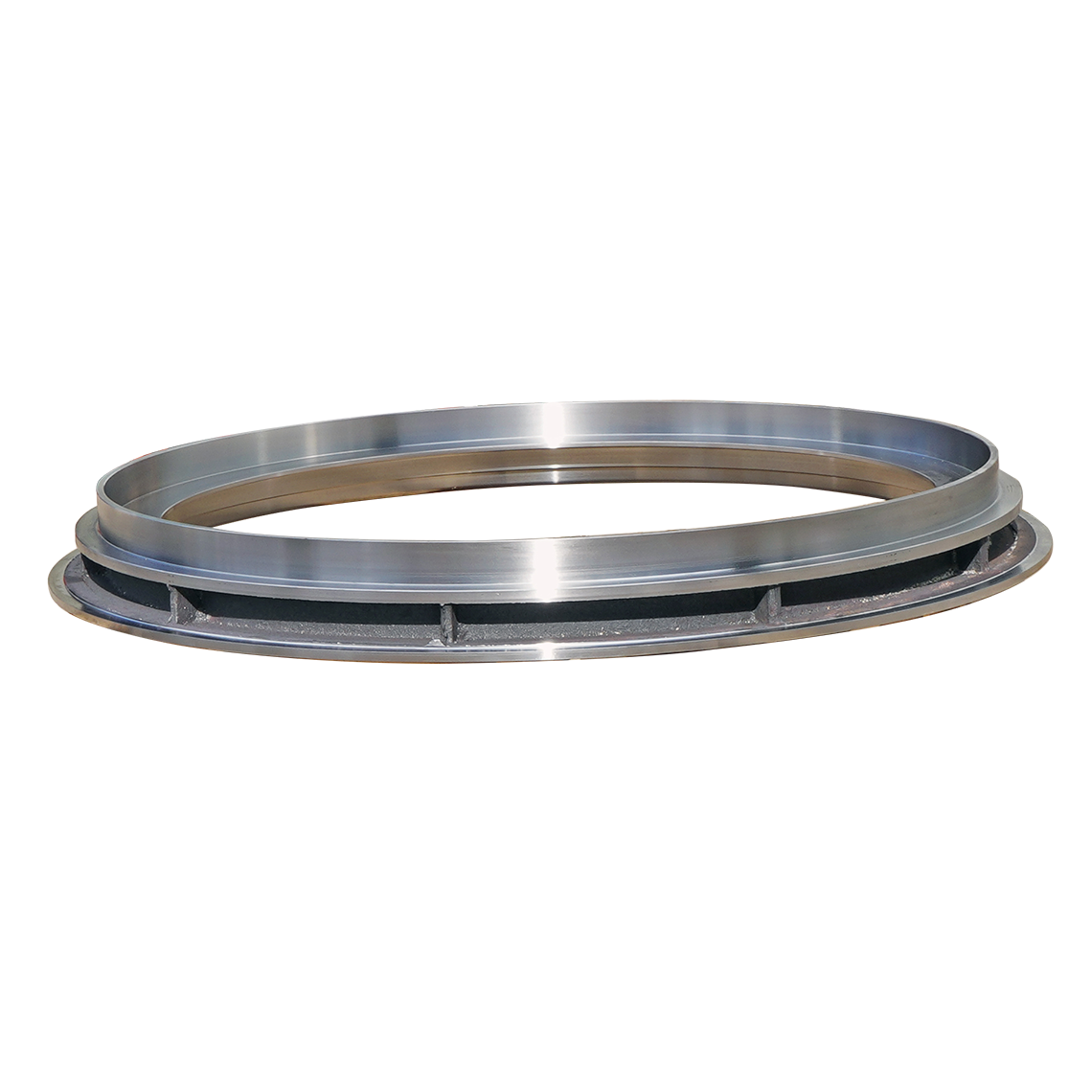

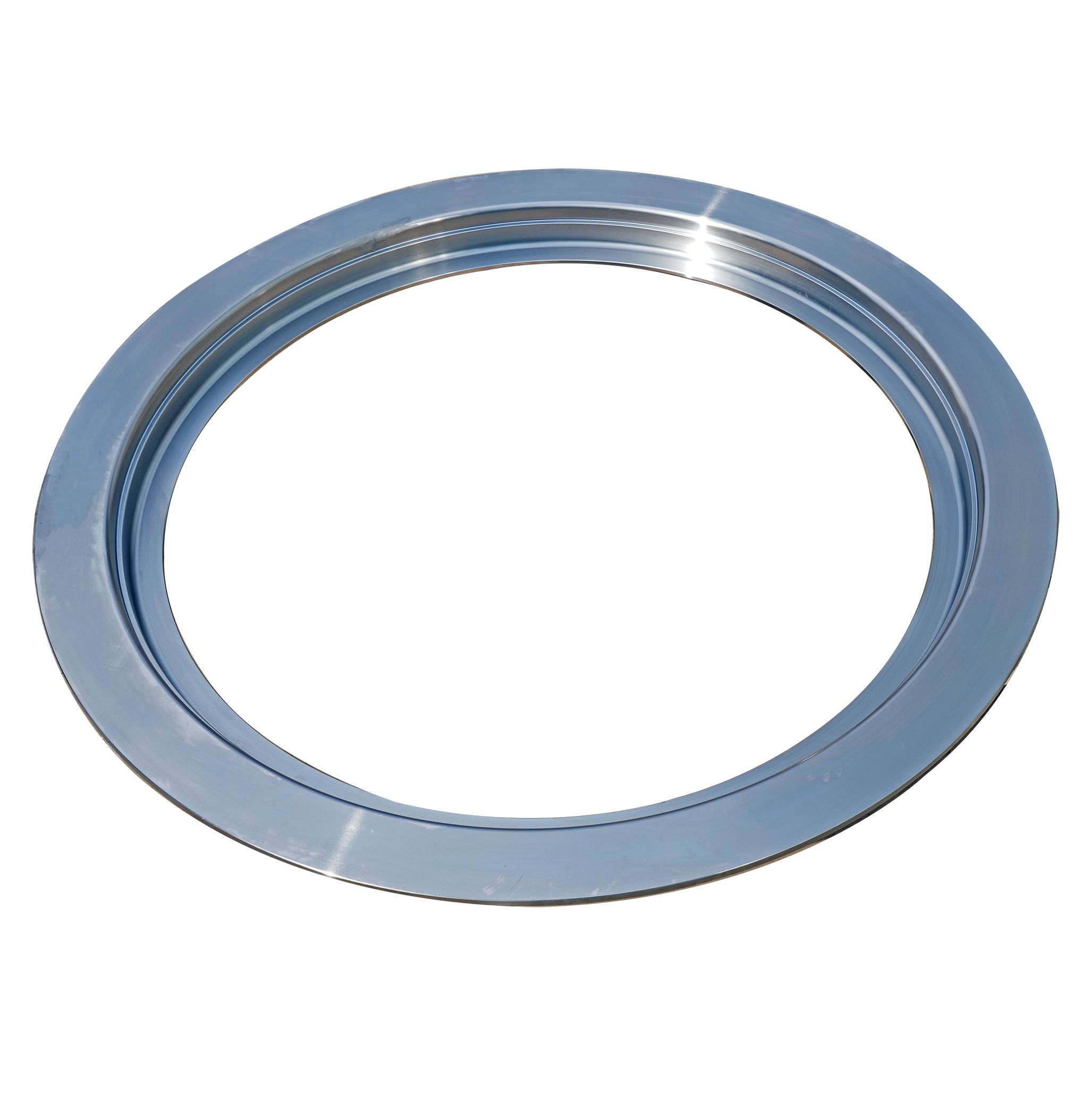

Technological innovation is focusing on material upgrades—particularly cast steel and ductile iron—and automated production processes for improved manufacturing efficiency and longer product lifecycle. As a result, products like the Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray have become pivotal components in reliable, large-scale concrete pipe production.

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 26, 2025 01:01 Back to list

Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Tray Supplier

Company: Shijiazhuang Casiting Trading Co., Ltd.

Phone: 0086-311-67596450 | Mobile: 008613832327186

Email: hjr1024@aliyun.com

Address: RM315, Baihui Building, No.57 Sizhong Road, Qiaoxi District, Shijiazhuang City, Hebei, China

Phone: 0086-311-67596450 | Mobile: 008613832327186

Email: hjr1024@aliyun.com

Address: RM315, Baihui Building, No.57 Sizhong Road, Qiaoxi District, Shijiazhuang City, Hebei, China

As a trusted industry leader,

Shijiazhuang Casiting Trading Co., Ltd.

delivers high-quality Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray

products for reinforced concrete and cement pipe manufacturing applications worldwide.

Industry Trends in Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray

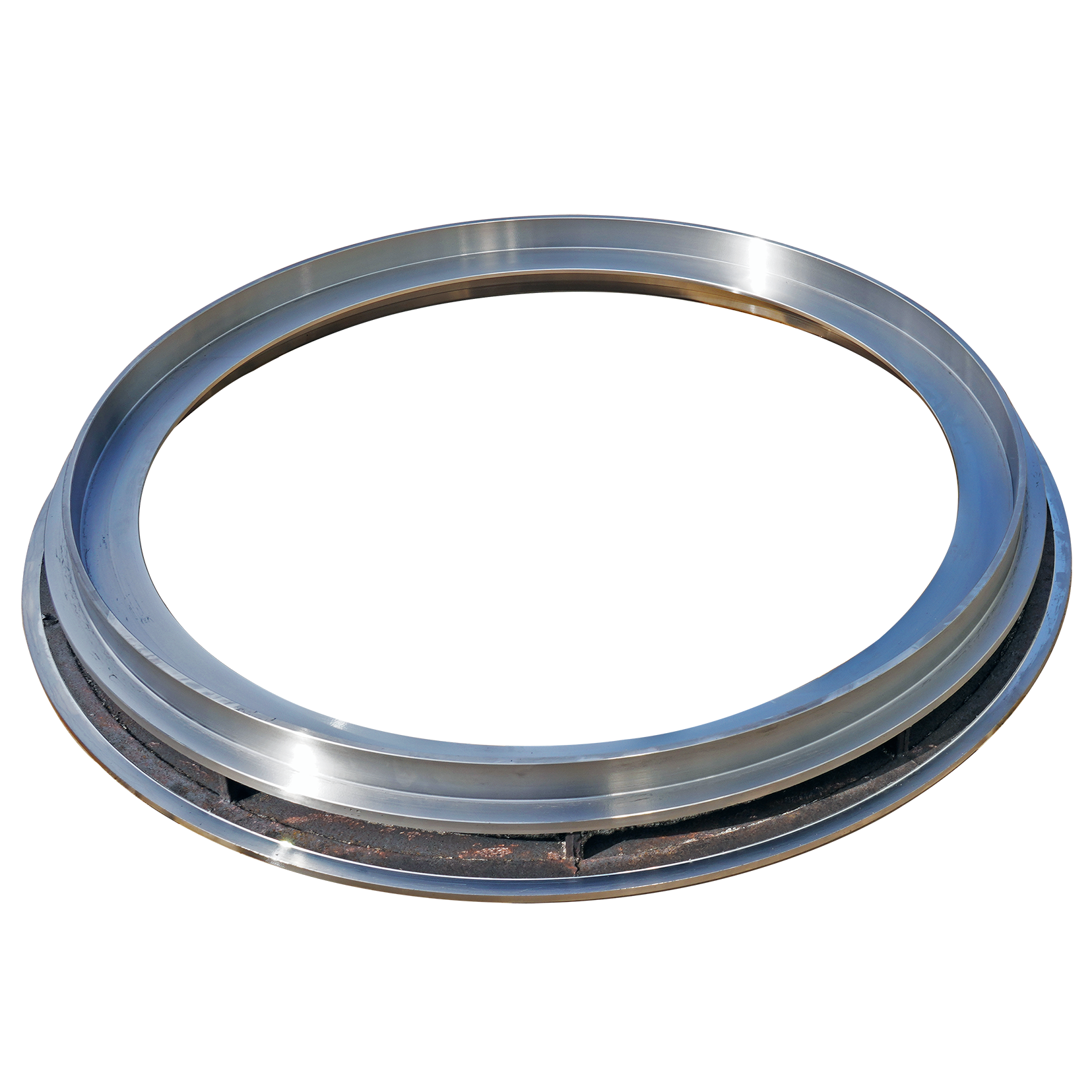

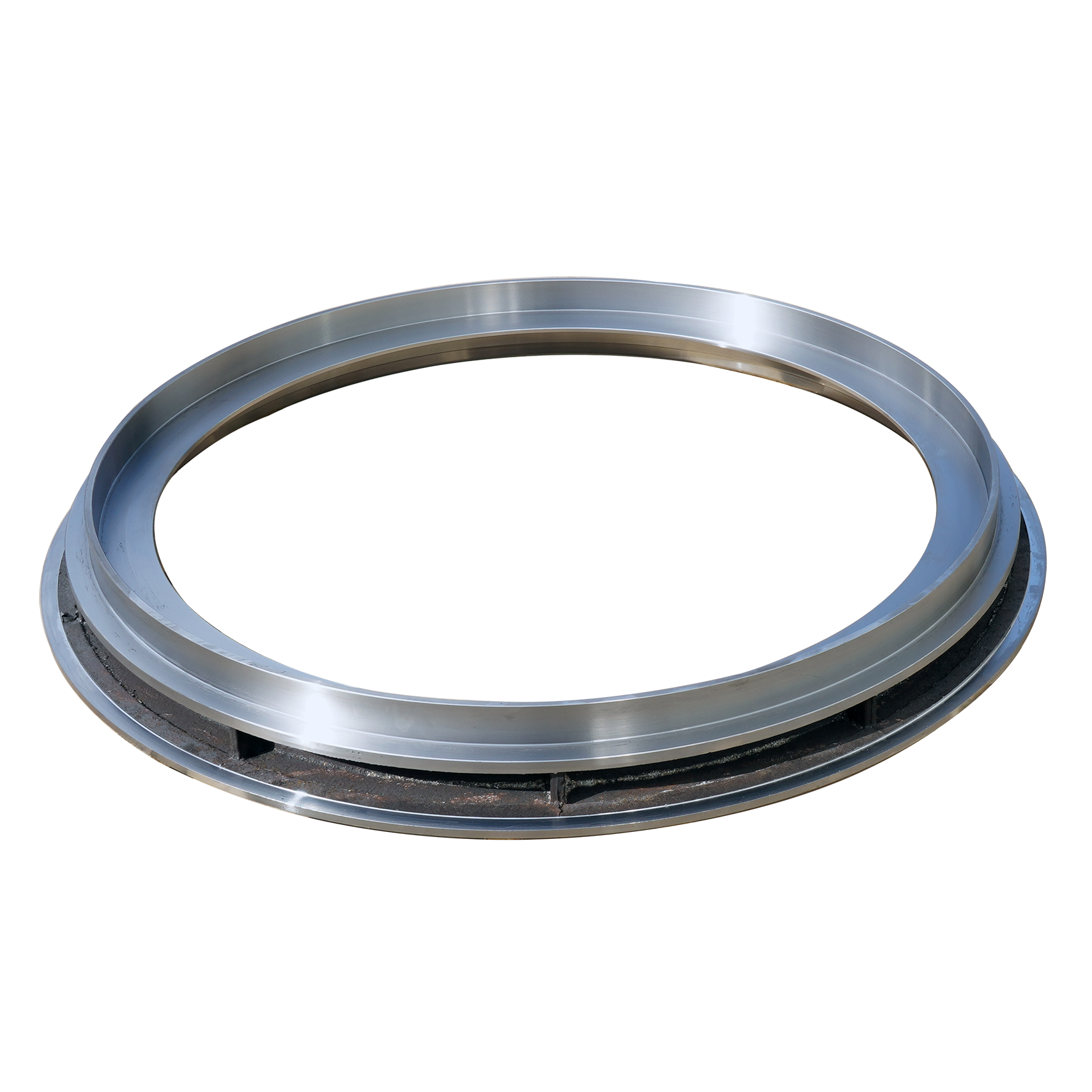

Product Details: Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray

- Product Name: Reinforced Concrete Pipe Mould Pallet/RCP Bottom Ring/Bottom Tray/Base Ring

- Material: Cast Steel, Ductile Cast Iron

- Technology: Casting, Annealing, Lathing

- Application: Reinforced Concrete Pipe Producing, Cement Pipe Manufacturing

- Delivery Terms: FOB Tianjin Xingang, FOB Qingdao port, CFR/CIF destination port

- Production Terms: Custom as per client drawings (ODM/OEM)

- Shipping: 20’ or 40’ OT/GP Container by Sea

- Website: Product Link

Key Technical Parameters Table

| Parameter | Specification Range | Unit | Notes |

|---|---|---|---|

| Material Grade | HT200—HT300, QT500-7, ZG230-450 | - | Casting standards as per GB/T9439/GB/T1348 |

| Outer Diameter | Φ300 – Φ3200 | mm | Customizable |

| Wall Thickness | 10 – 80 | mm | Defined by project |

| Weight | 80 – 3200 | kg | Depending on size |

| Surface Hardness | ≤ 220 (Cast Iron), ≤ 260 (Cast Steel) | HB | After annealing |

| Manufacturing Tolerance | ±0.2 – ±0.8 | mm | ISO 8062-3:2007 |

| Coating | Anti-rust paint, Custom Coating | - | Optional |

| Usage Life | 800 – 4000 | Cycles | Depending on maintenance |

Technical Parameter Trends & Data Visualization

Application Scenarios for Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray

- Civil infrastructure: municipal drainage and sewage pipelines

- Water supply pipelines for urban and rural utilities

- Irrigation projects in agriculture and horticulture

- Highway, railway and tunnel construction—culvert and stormwater passageways

- Industrial factory drainage systems

- Large-diameter, customized concrete pipe manufacturing

Expertise and Industry Authority

Shijiazhuang Casiting Trading Co., Ltd. boasts over 15 years of experience in high-grade casting and forging for concrete pipe manufacturing. The company's production strictly follows international standards like ISO 9001, EN 206, and relevant GB/T standards on cast iron and steel. Our technical specialists actively participate in global trade fairs, and our engineering solutions are frequently cited on professional forums and journals:

- Effectiveness of Cast Iron/Steel in High-Stress Pipe Moulds

- Industry FAQ on Casting Quality and Design

With a leading technical R&D team, advanced quality control laboratory, and a robust aftersales support network, Casiting ensures product reliability, traceability, and full compliance with international project requirements.

- Effectiveness of Cast Iron/Steel in High-Stress Pipe Moulds

- Industry FAQ on Casting Quality and Design

With a leading technical R&D team, advanced quality control laboratory, and a robust aftersales support network, Casiting ensures product reliability, traceability, and full compliance with international project requirements.

Professional FAQ: Technical Terms for Concrete Pipe Mold Solutions

1. What materials are typically used for Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray?

They are made from high-quality cast steel (ZG230-450) and ductile cast iron (QT500-7), offering superior mechanical properties, impact strength, and wear resistance essential for demanding pipe manufacturing cycles.

2. How is surface hardness ensured and what are standard values?

Surface hardness is achieved via controlled annealing and precision machining. Typical values are ≤260 HB (Cast Steel) and ≤220 HB (Cast Iron), per GB/T and ASTM A48 standards.

3. What is the role of annealing and lathing in production?

Annealing relieves internal stresses and refines grain structure for higher durability, while lathing ensures precise geometry and smooth surfaces for easy demoulding and repeatable concrete quality.

4. What sizes are available and can they be custom-made?

Standard sizes range from Φ300 mm up to Φ3200 mm, with wall thickness from 10 mm to 80 mm. Customized dimensions and profiles are available based on client’s detailed drawings and project needs.

5. What are the main coating options for corrosion protection?

Anti-rust primer, epoxy coating, and galvanization are popular choices, extending product service life—especially in high-humidity or aggressive chemical environments.

6. How is product quality assured by Shijiazhuang Casiting Trading Co., Ltd.?

Casiting applies 100% visual inspection, ultrasonic flaw detection, and dimensional checks. Each batch has a traceable QC record and full mechanical property test reports provided. Compliance with ISO 9001 ensures global quality acceptance.

7. How are Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray components installed?

Precise fitment on molding lines is achieved via CNC machining and tolerance control (±0.2 to ±0.8mm). The base rings and trays are designed for rapid mounting/dismounting, reducing plant downtime and ensuring high output.

Future Trends & Industry References

As digitalization progresses in the precast and infrastructure sectors, smart factories integrate IIoT (Industrial Internet of Things) solutions for concrete pipe manufacturing, which demands not only high-performance molds and base trays but also real-time monitoring and predictive maintenance. Sourcing reliable Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray components is thus becoming even more critical (Precast Concrete Institute).

For additional technical material and latest discussions on mold casting technology, refer to:

- ScienceDirect – Advances in Pipe Molding Technologies

- Concrete Pipe Industry Forum

- International Concrete Abstracts Portal

Contact Shijiazhuang Casiting Trading Co., Ltd. for customized, high-performance Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray solutions engineered for your project’s needs.

For additional technical material and latest discussions on mold casting technology, refer to:

- ScienceDirect – Advances in Pipe Molding Technologies

- Concrete Pipe Industry Forum

- International Concrete Abstracts Portal

Contact Shijiazhuang Casiting Trading Co., Ltd. for customized, high-performance Cast Steel Concrete Pipe Mold Reverse Base Ring Bottom Ring Pallets Bottom Tray Base Tray solutions engineered for your project’s needs.

Share

Next:

This is the last article

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025