- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ноя . 06, 2024 15:41 Back to list

OEM Foundry Products for High-Quality Casting Solutions and Custom Manufacturing

The Evolution of OEM Casting Products Meeting Modern Demands

In a world increasingly driven by technological advancement and customization, Original Equipment Manufacturer (OEM) casting products have emerged as a pivotal element in various industries. From automotive to aerospace, the significance of high-quality cast components cannot be overstated. This article explores the evolution and importance of OEM casting products, as well as their role in meeting modern manufacturing demands.

Understanding OEM Casting

OEM casting refers to the production of components that are produced for a specific company, which is then incorporated into their final products. This manufacturing process involves pouring molten metal into a mold to create parts that meet stringent specifications. The casting process can include various materials, including aluminum, iron, and steel, tailored to the specific needs of the industry.

One of the primary advantages of OEM casting is its ability to produce highly intricate designs with good dimensional accuracy. This capability is essential in industries where precision is critical. The ability to create complex shapes that may be challenging or costly to produce using other manufacturing methods makes OEM casting an attractive choice.

The Role of Technology in OEM Casting

The landscape of OEM casting has undergone significant transformation due to technological advancements. Computer-aided design (CAD) and simulation software play crucial roles in modern casting processes. These tools allow engineers to create precise digital models of components and simulate the casting process, optimizing the design for both functionality and manufacturability.

Additive manufacturing, or 3D printing, has also started to make its mark on the OEM casting industry. By creating sand molds or cores through 3D printing, manufacturers can significantly reduce lead times and costs. This innovation also allows for rapid prototyping, enabling companies to test and adapt designs quickly before large-scale production.

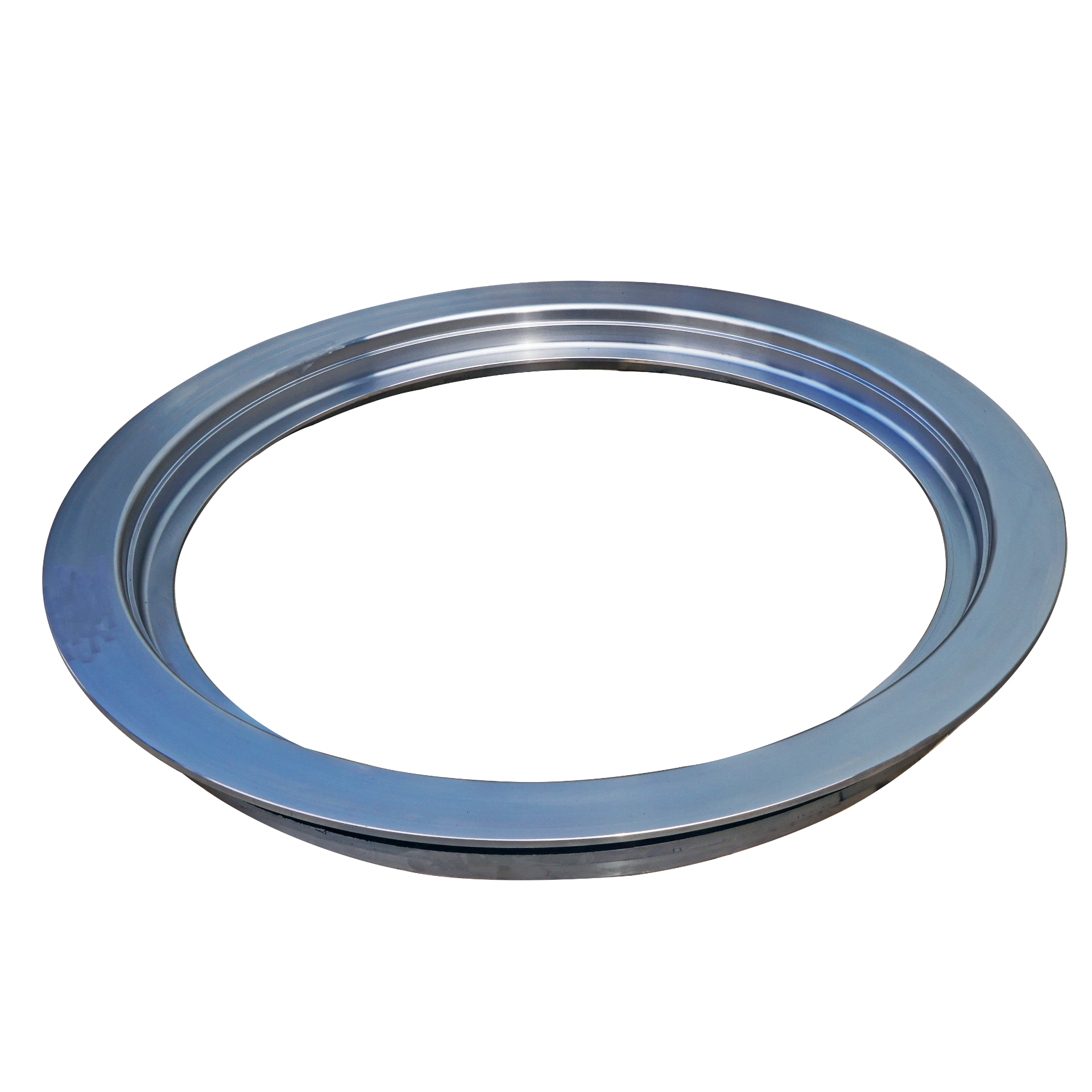

oem casting products

Sustainability in OEM Casting

As global focus shifts towards sustainability, the OEM casting industry is also adapting. Many manufacturers are striving to minimize their environmental footprint by adopting recycled materials and improving energy efficiency in their operations. The use of reclaimed metal and innovations in casting processes can significantly reduce waste and energy consumption.

Furthermore, advances in technology have enabled manufacturers to create lighter and more efficient parts, which are particularly important in the automotive and aerospace industries. Lightweight components contribute to improved fuel efficiency and reduced greenhouse gas emissions, aligning with global sustainability goals.

Customization and Market Demand

Today's consumers demand more personalized products, and OEM casting allows manufacturers to meet these expectations. The flexibility of the casting process enables companies to produce components in various sizes, shapes, and material compositions, catering to specific client needs. This level of customization is essential in industries such as automotive, where vehicles are often tailored to regional tastes and regulations.

In addition, the growing trend toward the Internet of Things (IoT) and smart technologies requires significant innovation in OEM casting. As industries integrate more advanced technologies into their products, the need for specialized components that can interface with these technologies increases. Manufacturers are responding to this shift by designing smarter casting solutions that accommodate electronic components, sensors, and communication devices.

Conclusion

In conclusion, OEM casting products are crucial to the contemporary manufacturing landscape. The evolution of technology, a commitment to sustainability, and an increasing demand for customization are shaping the future of this industry. As manufacturers continue to embrace innovation and respond to market needs, the significance of OEM casting products will undoubtedly grow, solidifying their position as a cornerstone of modern manufacturing. By understanding and harnessing the potential of OEM casting, industries can enhance their offerings, improve efficiency, and contribute to a more sustainable future.

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025

-

Custom Commercial Hot Water Heat Exchangers High-Efficiency Solutions

NewsMay.17,2025

-

Custom Fibre Reinforced Concrete Pipe Bottom Ring Moulds – Buy Durable Solutions

NewsMay.17,2025