- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Окт . 16, 2024 12:21 Back to list

Concrete Pipe Mould Pallet for Efficient Manufacturing Solutions

Understanding SRC Concrete Pipe Mould Pallets A Comprehensive Overview

Concrete pipes are integral to modern infrastructure, utilized in a variety of applications such as drainage systems, sewage transport, and even protective water channeling. The production of these pipes hinges significantly on high-quality moulds and pallets, which are crucial components of the manufacturing process. One such innovation in this domain is the SRC (Steel-Reinforced Concrete) pipe mould pallet. This article will delve into the advantages, manufacturing processes, applications, and considerations associated with SRC concrete pipe mould pallets.

What are SRC Concrete Pipe Mould Pallets?

SRC concrete pipe mould pallets are specifically designed platforms used to create concrete pipes through a moulding process. These pallets are reinforced with steel for added durability and strength, allowing them to withstand the immense pressure and stresses encountered during the concrete setting and curing stages. The combination of steel reinforcement and concrete offers an effective solution for producing high-quality, long-lasting pipes.

Advantages of SRC Concrete Pipe Mould Pallets

1. Enhanced Durability One of the primary benefits of SRC pallets is their durability. The steel reinforcement helps in resisting deformation and damage, extending the lifespan of the mould and ensuring consistent production quality over time.

2. Cost-Effectiveness Although the initial investment may be higher than standard concrete pallets, SRC mould pallets typically result in lower overall production costs. Their longevity reduces the need for frequent replacements, and their strength decreases the likelihood of production errors due to pallet failure.

3. Improved Production Efficiency The robust design of SRC pallets facilitates smoother operations in concrete pipe manufacturing. Their ability to maintain precise dimensions throughout the curing process leads to a reduction in waste and rework, enhancing overall efficiency.

4. Versatility SRC mould pallets can be customized to accommodate various sizes and shapes of concrete pipes, making them suitable for diverse applications. This adaptability allows manufacturers to respond quickly to changing market demands.

5. Environmental Benefits The longevity and durability of SRC pallets contribute to more sustainable manufacturing processes. Their extended lifecycle reduces material waste, and their efficient use of concrete helps minimize the environmental footprint of pipe production.

Manufacturing Process of SRC Concrete Pipe Mould Pallets

src concrete pipe mould pallet

The production of SRC concrete pipe mould pallets involves several key steps

1. Material Selection High-quality concrete and steel are selected based on the required specifications for strength and durability. The choice of materials directly impacts the performance of the final product.

2. Mould Fabrication Skilled artisans or automated machinery construct the moulds according to predetermined specifications. Precision in this stage is critical to ensure that the final concrete pipes meet industry standards.

3. Reinforcement Integration Steel rods or mesh are strategically placed within the mould to provide the necessary reinforcement. The arrangement of the reinforcement is essential for ensuring that the finished pallet withstands the rigors of concrete production.

4. Concrete Filling and Curing Once the mould is prepared, concrete is poured into the form and allowed to cure. This process can vary in time based on environmental conditions and the specific concrete formulation used.

5. Finishing and Quality Control After curing, the pallets undergo quality control checks to ensure they meet strict industry standards. Any necessary adjustments or repairs are made before the pallets are prepared for use in pipe production.

Applications of SRC Concrete Pipe Mould Pallets

SRC concrete pipe mould pallets are utilized across various sectors, including

- Civil Engineering For constructing drainage and sewage systems that require robust and durable pipes. - Infrastructure Development Provision of water transport infrastructures where the integrity of pipes is crucial. - Construction Utilized in the creation of stormwater management systems and maintenance of flood protection schemes.

Conclusion

SRC concrete pipe mould pallets represent a significant advancement in the concrete manufacturing industry, combining strength, durability, and efficiency. Their ability to withstand the rigors of production while ensuring high-quality outputs makes them an indispensable tool in the production of concrete pipes. As infrastructure demands continue to grow, the adoption of SRC mould pallets will likely increase, further enhancing the quality and longevity of concrete piping solutions. Investing in these advanced tools not only promotes sustainability but also supports the advancement of modern construction practices.

-

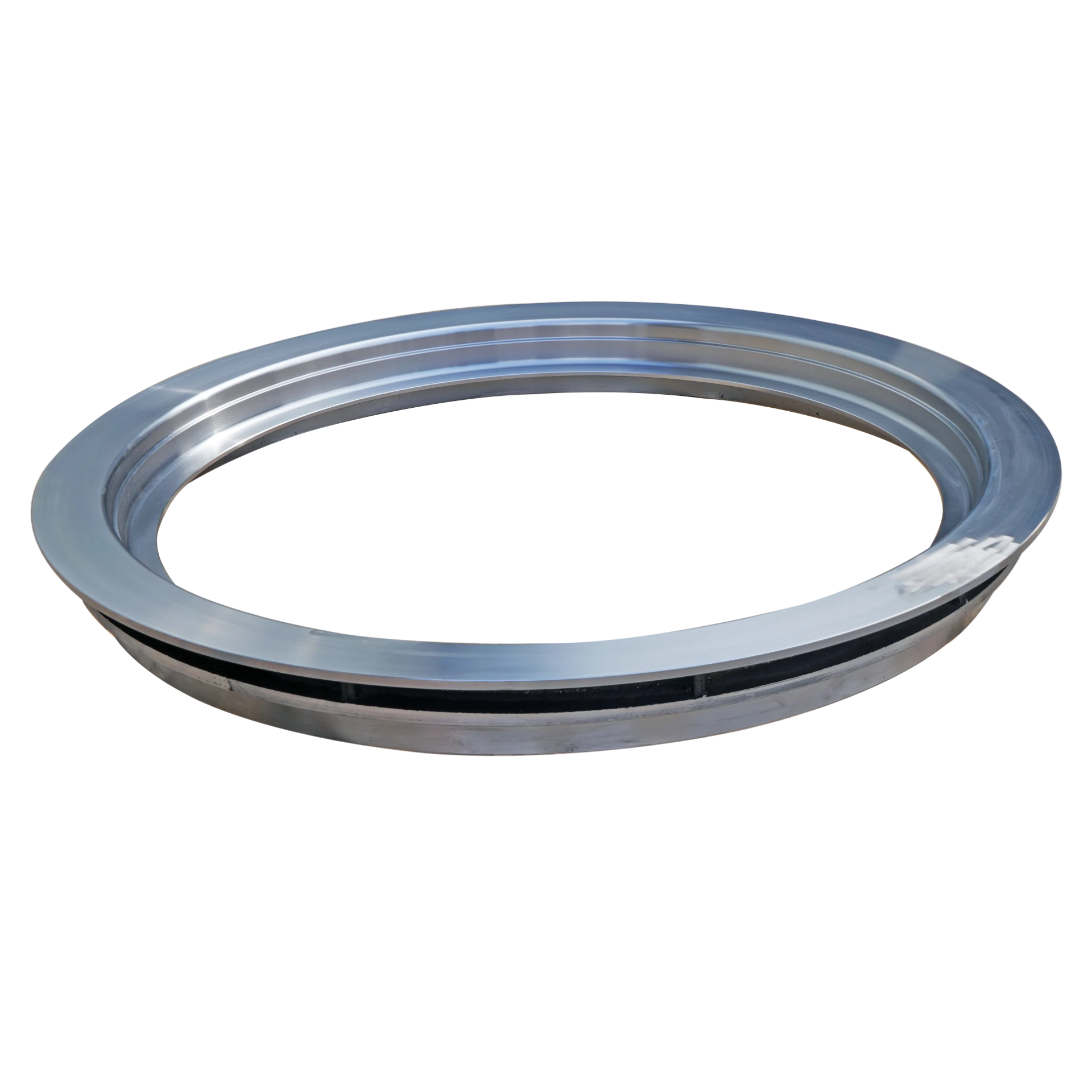

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025