- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

نويابىر . 15, 2024 03:42 Back to list

cast aluminum silicon radiator casting supplier

The Advantages of Cast Aluminum Silicon Radiator Castings and Supplier Insights

In the realm of automotive and industrial applications, the demand for efficient and reliable heat management systems has driven innovation in radiator technology. Among the materials leading this charge is cast aluminum, specifically aluminum silicon alloys, which are favored for their remarkable properties. With their superior thermal conductivity, lightweight nature, and resistance to corrosion, these materials make for excellent radiator castings. In this article, we will explore the benefits of cast aluminum silicon radiator castings and considerations for selecting a reliable supplier.

Understanding Cast Aluminum Silicon Alloys

Cast aluminum silicon alloys are a combination of aluminum and silicon, often augmented with other elements to enhance specific properties. The presence of silicon in the alloy significantly improves fluidity during the casting process, allowing intricate designs and thin-walled sections that are consistently difficult to achieve with traditional materials. These alloys also boast commendable thermal conductivity, facilitating efficient heat dissipation—an essential feature for any radiator used in high-performance applications.

The lightweight nature of aluminum is another advantage, contributing to overall vehicle efficiency by reducing weight without sacrificing performance. This characteristic is particularly important in the automotive industry, where every gram counts in the pursuit of better fuel efficiency and lower emissions.

Benefits of Using Cast Aluminum Silicon Radiator Castings

1. Superior Thermal Performance The exceptional thermal conductivity of aluminum silicon alloys ensures that radiators can dissipate heat efficiently, preventing engine overheating and maintaining optimal operating temperatures.

2. Corrosion Resistance Cast aluminum provides natural resistance to corrosion, which is crucial for radiators exposed to various environments. This resistance prolongs the lifespan of the radiator and reduces maintenance costs.

3. Design Flexibility The casting process allows for complex geometries, enabling manufacturers to produce radiators that meet specific design requirements while maximizing performance.

cast aluminum silicon radiator casting supplier

5. Eco-Friendly Aluminum is highly recyclable, making it an environmentally friendly choice that aligns with modern sustainability efforts. The recycling process requires less energy compared to the extraction of new aluminum, reducing overall environmental impact.

Choosing the Right Supplier for Cast Aluminum Silicon Radiators

When considering the purchase of cast aluminum silicon radiator castings, selecting a reputable supplier is paramount. Here are some tips for identifying a reliable manufacturer

1. Experience and Expertise Look for suppliers with a proven track record in producing aluminum silicon castings. An experienced supplier will understand the intricacies of the casting process and ensure high-quality standards.

2. Certifications and Quality Standards Ensure that the supplier adheres to industry standards and possesses relevant certifications, such as ISO 9001, which attest to their commitment to quality.

3. Customization Options A capable supplier should offer customization services to meet specific design requirements, providing flexibility that caters to unique applications.

4. Client References Request references or case studies from previous clients to gauge the supplier's reliability and the quality of their products.

5. Support and Communication Effective communication is essential for a smooth partnership. Choose a supplier that provides solid customer support and is responsive to your inquiries.

In conclusion, cast aluminum silicon radiator castings are an excellent choice for applications requiring effective heat management. Their combination of thermal efficiency, lightweight structure, and resistance to corrosion makes them invaluable in various industries. By selecting a reliable supplier, businesses can ensure the quality and performance of their radiator systems, contributing to the overall success of their operations.

-

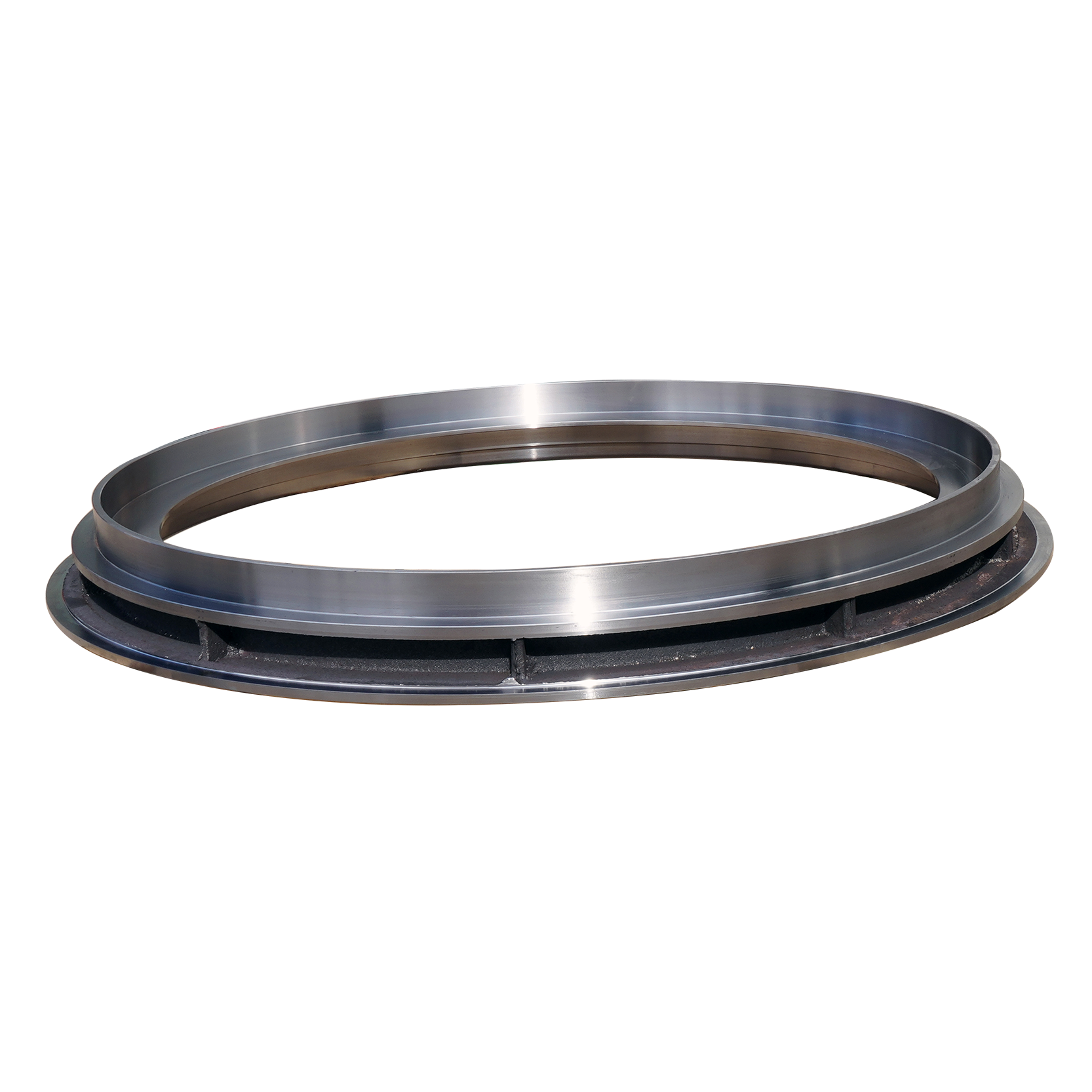

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025