- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ئۆكتەبىر . 02, 2024 11:54 Back to list

Cast Aluminum Heat Exchangers for Efficient Hot Water Boiler Applications

Cast Silicon Aluminum Heat Exchanger for Hot Water Boilers An Overview

In the realm of thermal management and energy efficiency, the materials and designs of heat exchangers play a crucial role in optimizing performance. Among the various materials available, cast silicon aluminum has emerged as a preferred choice for heat exchangers in hot water boilers. This article delves into the advantages and applications of cast silicon aluminum heat exchangers, examining their contribution to enhancing boiler efficiency and sustainability.

Understanding Heat Exchangers

Heat exchangers are devices that facilitate the transfer of heat between two or more fluids at different temperatures, without them coming into direct contact. They play a vital role in many industries including power generation, HVAC, and automotive systems. In hot water boilers, heat exchangers enable the efficient transfer of heat from the combustion process to the water being heated, ensuring optimal energy utilization.

Why Cast Silicon Aluminum?

Cast silicon aluminum, an alloy composed primarily of aluminum with silicon content, offers several benefits that make it suitable for heat exchanger applications. The primary advantages include

1. Corrosion Resistance One of the key challenges faced by heat exchangers is corrosion, especially in environments where water and air interact. The alloy's unique composition provides excellent resistance to corrosion, which prolongs the lifespan of the heat exchanger and reduces maintenance costs.

2. Improved Thermal Conductivity Cast silicon aluminum exhibits superior thermal conductivity compared to many other materials. This property allows for more efficient heat transfer, resulting in improved performance of the hot water boiler. Enhanced thermal performance means that less energy is required to achieve desired water temperatures, ultimately leading to cost savings.

cast silicon aluminum heat exchanger for hot water boiler

3. Lightweight and Durable The lightweight nature of cast silicon aluminum makes it easier to handle and install. Coupled with its durability, it effectively supports the operational demands of hot water heaters, making it an ideal choice for both residential and industrial applications.

4. Malleability and Castability The manufacturing process for cast silicon aluminum allows for intricate designs that can enhance fluid dynamics within the heat exchanger. This adaptability enables engineers to create systems tailored to specific operational requirements, optimizing overall efficiency.

Applications in Hot Water Boilers

The versatility of cast silicon aluminum heat exchangers allows them to be utilized in various types of hot water boilers. From residential units to large commercial systems, these heat exchangers are integral to maintaining high efficiency and performance standards. They are particularly beneficial in condensing boilers, where the recovery of latent heat from exhaust gases significantly improves fuel utilization.

In addition, the use of cast silicon aluminum is becoming increasingly popular in renewable energy applications, such as solar water heating systems and geothermal heat pumps. As the industry moves towards more sustainable practices, heat exchangers featuring this alloy contribute to reducing carbon footprints and enhancing energy efficiency.

Conclusion

As energy efficiency and sustainability continue to be focal points in modern engineering, the adoption of cast silicon aluminum heat exchangers in hot water boilers stands out as a forward-thinking solution. With their superior thermal performance, corrosion resistance, and lightweight properties, these heat exchangers facilitate effective heat transfer in various applications, from residential boilers to industrial systems. As technology evolves, the role of innovative materials like cast silicon aluminum will be critical in meeting the increasing demands for efficiency and sustainability in thermal management systems.

In summary, embracing cast silicon aluminum technology not only enhances the performance of hot water boilers but also aligns with the broader trend towards sustainable energy practices, paving the way for a more efficient future.

-

High-Efficiency Domestic Heating Heat Exchangers Custom Designs

NewsMay.21,2025

-

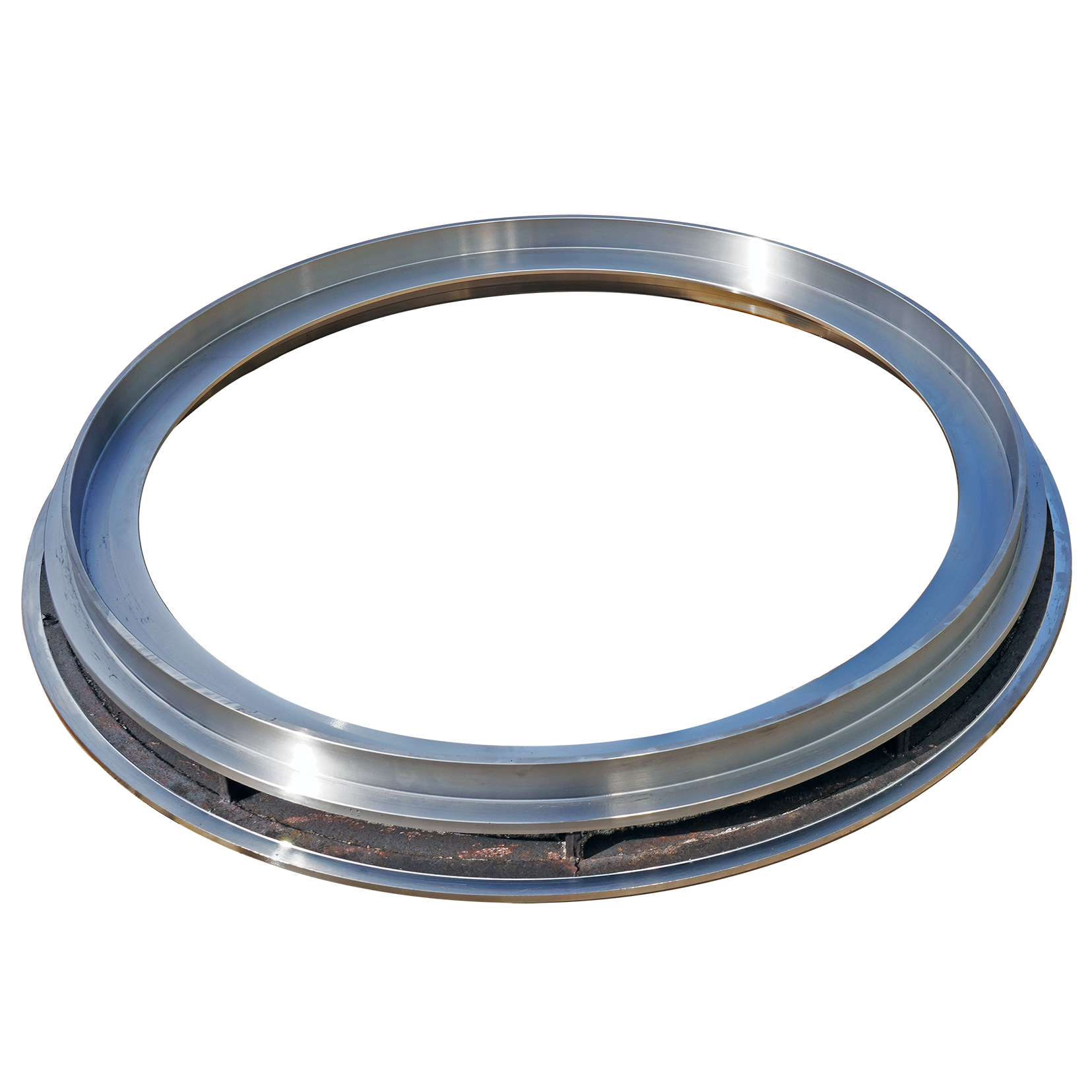

Premium Cast Steel Pipe Mold Bottom Ring Custom & ODM Solutions

NewsMay.21,2025

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025