- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

دېكابىر . 24, 2024 16:33 Back to list

Exploring Innovative Factory Solutions for Enhanced Efficiency and Productivity

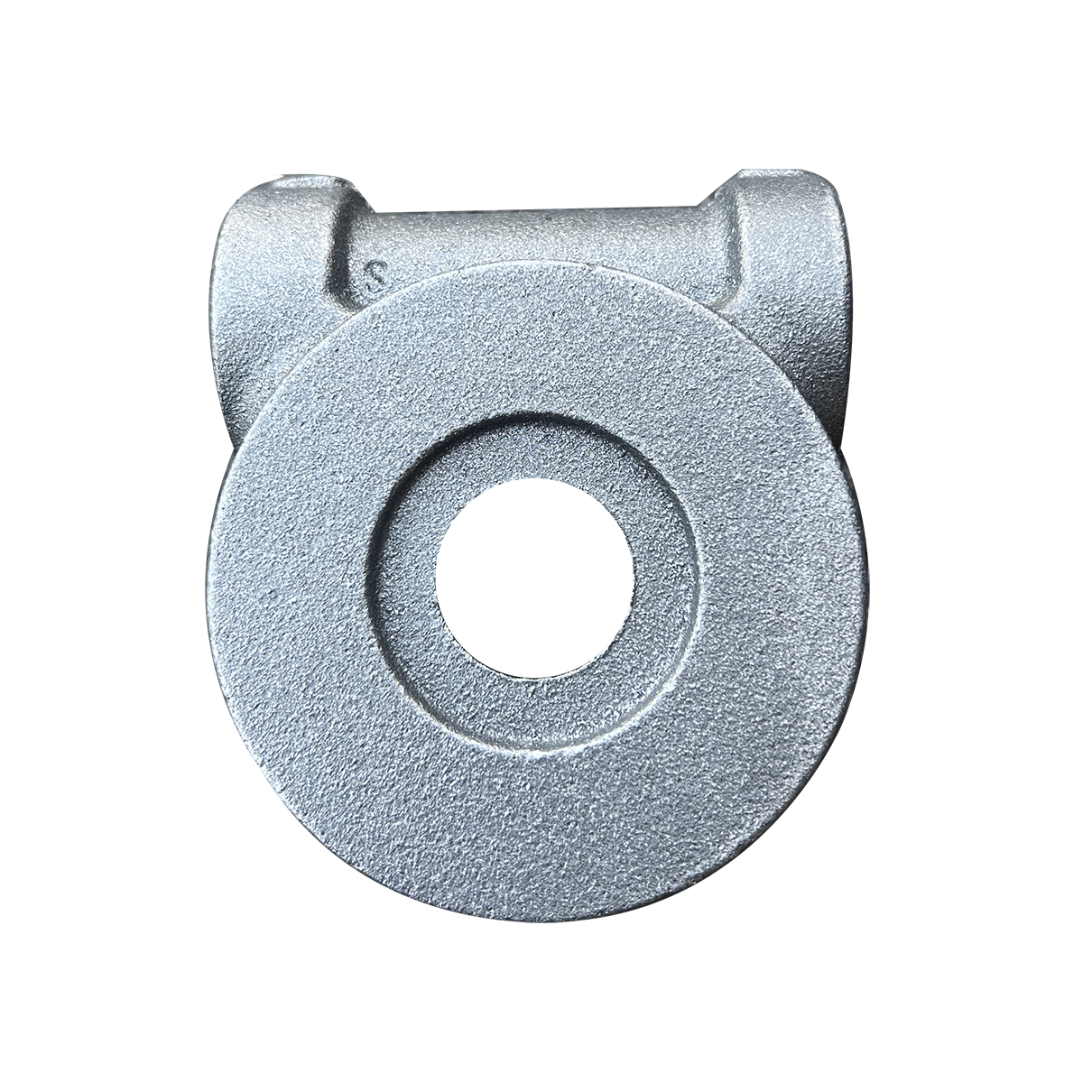

Understanding Handle Factories A Comprehensive Overview

In today's manufacturing and design landscape, the need for efficiency and innovation has led to the emergence of various specialized process systems and methodologies. One such system that has gained prominence is the concept of handle factories. Handle factories are specialized production facilities focused on the creation of handles for a wide array of products, ranging from consumer goods to industrial equipment. This article delves into the significance, process, and advantages of handle factories in contemporary manufacturing.

The Importance of Handle Factories

Handles are ubiquitous in everyday life, found on everything from kitchen appliances to luggage and industrial machinery. The design and functionality of a handle play a crucial role in user experience. A well-designed handle enhances usability, safety, and aesthetics. Handle factories cater specifically to the demand for high-quality, ergonomic handles, ensuring that products meet both consumer expectations and regulatory standards.

These factories often employ advanced manufacturing techniques, including injection molding, die casting, and 3D printing. The specialized focus allows companies to optimize their production processes, reduce waste, and improve product quality. With rising consumer expectations, especially regarding sustainability, handle factories are also incorporating eco-friendly materials and processes into their operations.

The Process of Handle Manufacturing

The manufacturing process in handle factories typically starts with design. Designers and engineers work together to create prototypes, considering factors such as ergonomics, material strength, and aesthetic appeal. Once a design is finalized, the production process begins, which can be broken down into several key stages

1. Material Selection Choosing the right materials is crucial. Handles can be made from various substances, including plastics, metals, and composites. The choice depends on the product's requirements, such as weight, cost, and usage environment.

2. Molding and Shaping Depending on the selected materials, different methods can be used to shape the handles. Injection molding is popular for plastic handles, while die casting is commonly used for metal handles. Each method has its unique advantages in terms of cost, time, and material properties.

3. Finishing After shaping, handles often undergo finishing processes such as sanding, painting, or plating. These steps enhance the handle's durability, aesthetic appeal, and resistance to wear and tear.

handle factories

4. Quality Control Rigorous testing and quality assurance protocols are essential in this stage. Handles are tested for strength, durability, and functionality to ensure they meet safety standards.

5. Distribution Finally, the manufactured handles are packaged and distributed to clients, ready for integration into finished products.

Advantages of Handle Factories

Handle factories bring numerous benefits to the manufacturing sector

- Specialization By focusing solely on handles, these factories can achieve higher efficiency and quality in production. They can dedicate resources to perfecting handle design and production techniques.

- Innovation The concentration of expertise fosters innovation, allowing for the development of cutting-edge designs and materials that enhance functionality and user experience.

- Cost-Effectiveness Specialized factories can often reduce costs through streamlined operations and bulk purchasing of materials. This translates into savings for manufacturers who outsource handle production.

- Sustainability With a growing focus on environmentally friendly practices, many handle factories are adopting sustainable materials and processes, catering to eco-conscious consumers and businesses.

Conclusion

Handle factories exemplify the intersection of design, functionality, and manufacturing excellence. By specializing in handle production, these facilities not only improve the quality and efficiency of handles but also contribute to the overall enhancement of product usability. As market demands continue to evolve, the role of handle factories will likely expand, integrating new technologies and sustainable practices to meet the needs of an increasingly discerning consumer base. Whether in the realm of household items or complex machinery, the significance of expertly crafted handles cannot be overstated.

-

Ductile Iron Casting Solutions High-Strength & Corrosion-Resistant

NewsMay.13,2025

-

Custom Low Nitrogen Condensing Gas Boilers for Domestic Hot Water

NewsMay.13,2025

-

EN877 Grey Cast Iron Pipe Casting Custom Epoxy Coating Solutions

NewsMay.12,2025

-

Cast Silicon Aluminum Heat Exchanger for Commercial Boilers High Efficiency

NewsMay.12,2025

-

Custom Colloidal Silica Casting High-Precision & Durable Solutions

NewsMay.11,2025

-

Premium Metal Sand Casting Services Custom & ODM Solutions

NewsMay.11,2025