- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Жов . 19, 2024 07:24 Back to list

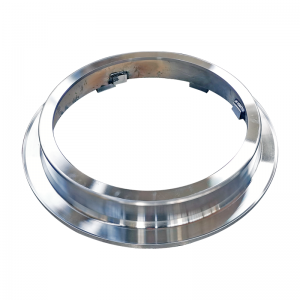

punch concrete pipe mold bottom ring manufacturer

The Importance of Punch Concrete Pipe Mold Bottom Ring Manufacturers

In the construction industry, efficiency, durability, and precision are paramount. One of the key components in the production of concrete pipes is the mold, especially the bottom ring mold, which plays a critical role in shaping and strengthening these essential structures. Punch concrete pipe mold bottom ring manufacturers are at the forefront of this vital process, and understanding their significance requires a closer look at the function and benefits of their products.

Understanding Punch Concrete Pipe Mold Bottom Rings

Concrete pipes are used extensively in various applications, including drainage, sewer systems, and water transportation. The design and integrity of these pipes depend heavily on the quality of the molds used in their fabrication. The bottom ring of a concrete pipe mold is particularly crucial, as it provides the foundational support and shape for the pipe during the curing process.

Punch concrete pipe mold bottom rings are engineered with precision to ensure a perfect fit and to enable easy removal of the finished product. These molds are designed with strength in mind, utilizing high-grade materials that withstand the rigors of repetitive use while maintaining their dimensional accuracy. The punch aspect refers to the method used to create openings or holes in the mold, allowing for better drainage and air circulation, which is vital during the curing phase.

Advantages of Quality Manufacturing

1. Enhanced Durability High-quality manufacturers use robust materials, such as steel or reinforced composites, which enhance the durability of the molds. This means fewer replacements and repairs in the long run, translating to lower operational costs for concrete pipe producers.

2. Precision and Consistency Advanced manufacturing techniques employed by reputable manufacturers ensure that each bottom ring mold is produced to exact specifications. This precision is critical, as it guarantees that every pipe is uniform in size and shape, which is essential for fitting during installation and when joining multiple pipes together.

punch concrete pipe mold bottom ring manufacturer

3. Cost-Effectiveness Investing in high-quality punch concrete pipe mold bottom rings can lead to significant cost savings over time. Although the initial investment may be higher, the longevity and reliability of these molds reduce waste and increase productivity, providing a better return on investment.

4. Customization Many manufacturers understand that each project may have unique requirements. As such, they offer customizable options to meet specific needs, whether it’s altering the dimensions, weight, or material composition of the mold. This flexibility allows producers to cater to diverse market demands effectively.

5. Technical Support Reputable manufacturers often provide excellent customer service and technical support, which can be invaluable for companies that may encounter issues with mold usage or maintenance. This support can help prevent costly downtime and ensure that production flows smoothly.

The Manufacturing Process

The process of creating punch concrete pipe mold bottom rings is meticulous. It involves several stages, including design, material selection, machining, and finishing. Advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining are often employed to enhance precision and efficiency. The finishing process involves treating the molds to resist corrosion and improve their lifespan, ensuring that they remain functional under rigorous manufacturing conditions.

Conclusion

Punch concrete pipe mold bottom ring manufacturers are a critical component of the concrete pipe production industry. Their focus on durability, precision, and customization reflects the broader trends toward efficiency and quality in construction. By investing in high-quality molds, concrete manufacturers can ensure that their products meet the demanding standards of today's infrastructure projects. As the construction landscape continues to evolve, the role of these manufacturers will remain integral, driving innovation and excellence in concrete pipe production.

In summary, understanding the importance of punch concrete pipe mold bottom rings and their manufacturers is essential for anyone involved in the construction industry. The blend of innovation, precision engineering, and customer support they offer positions them as key players in the ongoing development of reliable and effective concrete solutions.

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025