- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

دسمبر . 01, 2024 17:29 Back to list

cross flow condenser

Understanding Cross Flow Condensers Principles and Applications

Cross flow condensers play a vital role in various industrial processes, particularly in power plants, chemical production, and refrigeration systems. These heat exchangers are designed to effectively transfer heat from vapor to a cooling medium, solidifying the vapor into liquid form, and are essential components in enhancing energy efficiency and optimizing thermal systems.

Working Principle

The fundamental working principle of a cross flow condenser is based on the efficient exchange of heat between two fluids the vapor that needs to be condensed and the cooling fluid, usually water or air. In a cross flow configuration, one fluid flows horizontally while the other flows vertically. This arrangement significantly increases the surface area for heat transfer and minimizes the heat exchange resistance, making the process more efficient.

When vapor enters the condenser, it comes into contact with tubes or plates that carry the cooling medium. As the vapor loses heat, its temperature drops, and it condenses into a liquid state. The cooling medium absorbs this heat, raising its temperature in the process. Because the fluids flow in perpendicular directions, the heat exchange occurs more effectively, allowing for a smaller condenser design compared to parallel flow condensers.

Design Considerations

Several factors as well as design parameters determine the efficiency and performance of a cross flow condenser. The choice of materials, tube diameter, and surface area are crucial elements for optimizing heat transfer. Additionally, the flow rates of both the vapor and cooling fluid must be balanced to avoid issues such as vapor breakout or insufficient cooling.

The arrangement of the tubes also influences performance. Typically, condensers are designed with either finned or smooth tubes. Finned tubes enhance heat transfer by increasing the surface area, which is particularly useful in applications with lower heat transfer fluids. Conversely, smooth tubes are more suitable for high-velocity fluid applications where erosion could be a concern.

cross flow condenser

Applications

Cross flow condensers find widespread applications across numerous industries. In power generation, they are integral to the steam cycles of thermal power plants, where they facilitate the condensation of exhaust steam from the turbine back into the water, ready to be reused in the boiler. This recycling of water not only conserves resources but also increases the overall efficiency of the plant.

In chemical processing, cross flow condensers are used in distillation columns to cool vapors exiting the column, allowing for effective separation of components based on their boiling points. Similarly, in refrigeration systems, these condensers help reject heat from the refrigerant, allowing it to condense back into a liquid and complete the refrigeration cycle.

Energy Efficiency and Sustainability

The significance of cross flow condensers extends beyond mere functionality; they are essential for achieving energy efficiency and sustainability in industrial operations. By minimizing energy losses during the condensation process, these systems contribute to reduced operational costs and lower environmental footprints. Enhanced designs and materials are continually being researched to improve performance further and increase the longevity of condensers.

Modern advancements in technology, including computational fluid dynamics (CFD), allow engineers to simulate and analyze the thermal and hydraulic performance of condensers before physical prototypes are built. This helps in optimizing designs to meet specific application requirements, thus improving efficiency and effectiveness in energy usage.

Conclusion

Cross flow condensers are crucial components in many heat transfer applications. Their unique design and operational principles allow for efficient condensation and are integral to the energy efficiency of various industrial processes. Understanding their workings, design considerations, and applications can help industries optimize their thermal systems, thus contributing to a more sustainable industrial landscape. As industries continue to focus on reducing energy consumption and environmental impacts, the importance of effective heat exchangers like cross flow condensers will continue to grow.

-

Silica Sol Casting Supplier – Custom, ODM & Buy Services High Precision Casting Solutions

NewsJun.10,2025

-

High-Performance AODD Pumps for Diverse Applications Buy Custom & ODM AODD Solutions Online

NewsJun.10,2025

-

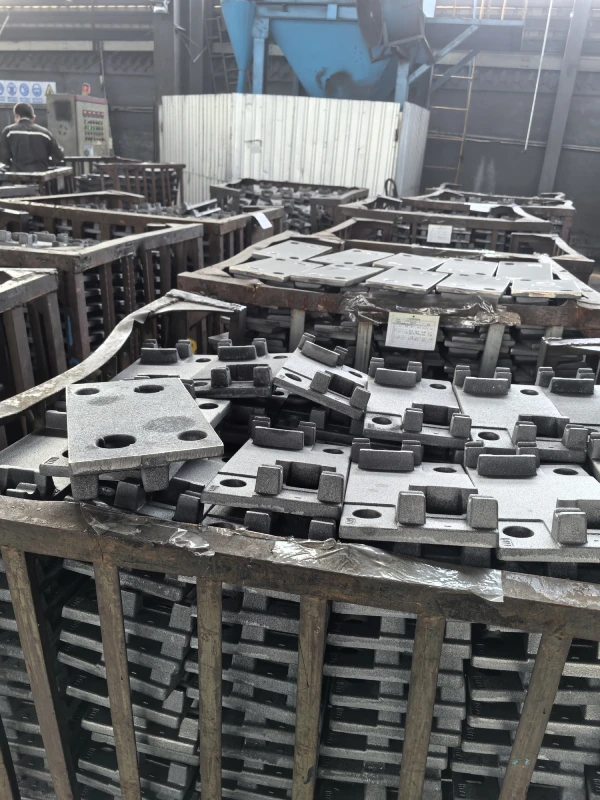

High-Quality Casting Machinery Parts Custom & ODM Services Available

NewsJun.10,2025

-

Premium Punching Cement Concrete Pipe Mold Pallets Custom ODM Available

NewsJun.10,2025

-

Premium Cast Aluminum Silicon Radiator Castings For Sale

NewsJun.10,2025

-

Custom Cast Steel Pipe Mold Pallet for Durable Precision

NewsJun.10,2025