In the evolving world of urban infrastructure and industrial conveyance, cast iron water main pipe remains a trusted backbone. With the maturation of centrifugally cast iron technology alongside sand and ductile iron casting, the utility and diversification of cast iron pipe products continue to grow. This guide delivers a deep-dive overview on cast iron water main pipe industry trends, technical parameters, application scenarios, and the state-of-the-art products and services offered by Shijiazhuang Casiting Trading Co., Ltd., an industry authority.

The cast iron water main pipe has been a staple in water distribution and industrial piping networks for centuries, prized for its durability, corrosion resistance, and structural robustness. Modern advancements—primarily via centrifugally cast iron pipe technology—have further improved mechanical strength, lining quality, and lifespan metrics.

With ongoing urbanization and heightened demands for dependable water distribution, the industry’s shift toward higher-specification and custom-fabricated pipes is unmistakable. Standards such as AWWA C151, ISO 2531, and EN 545 are widely pursued to optimize performance and ensure compliance.

- Resurgence in Urban Upgrades: Increasing replacement of aging pipelines favors ductile cast iron pipe and cast iron drain pipes for sale due to their high tensile strength and reliability.

- Eco-Friendly Solutions: With a focus on minimising environmental footprints, manufacturers employ recyclable materials and maximize pipe lifespan through improved coatings.

- Customization and Precision Engineering: Greater application-tailored production (via both OEM and ODM) addresses diverse client needs: from cast iron heating pipes to cast iron conduit for telecommunication or industrial sites.

- Global Standardization: Adoption of unified codes for dimensions—including cast iron outside diameter—to streamline engineering and project integration.

Source: WaterOnline - Pipe Material Overview

| Parameter | Specification | Description | Industry Standard |

|---|---|---|---|

| Material | Cast Iron / Ductile Cast Iron | ZG30MnSi, EN-GJS-400-15 and more | ISO 2531 / EN 545 |

| Nominal Diameter (DN) | DN80 - DN2600 mm | Standard outside diameters for various applications | AWWA C151 |

| Wall Thickness | 6 mm - 22 mm | Ensures durability and pressure rating | ISO 2531 |

| Length | 6m (customizable) | Optimized for transport and installation | EN 598 |

| Pressure Rating | PN10 / PN16 / PN25 | Adaptable to potable, industrial, and municipal systems | ISO 2531 |

| Coating | Bitumen, Epoxy, Zinc | Anti-corrosion and enhanced pipe longevity | AWWA C104 |

Chart reflects upward technical trends for cast iron water main pipe: higher pressure, larger diameters, and thicker walls.

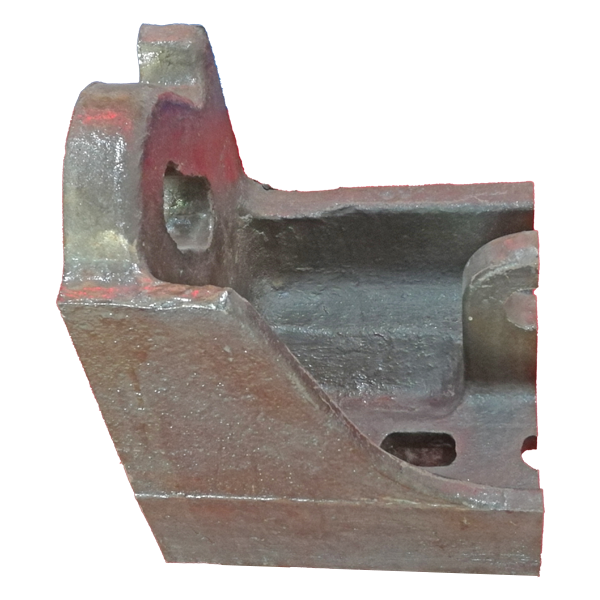

Short Description:

- Material: ZG30MnSi

- Usage: Accessory for coal mine conveying equipment

- Casting Technology: Sand casting

- Unit Weight: 1900Kgs

- Productivity: 20,000 tons/year

- ODM, OEM based on customer drawings: Yes

| Product | Material | Weight (kg) | Productivity (ton/year) | OEM/ODM |

|---|---|---|---|---|

| Inblock Cast Service | ZG30MnSi | 1900 | 20000 | Yes |

| Monoblock Cast Service | ZG30MnSi | 1880 | 20000 | Yes |

| Integral Casting Service | ZG30MnSi | 1895 | 20000 | Yes |

| Made in Cast Steel | ZG30MnSi | 1910 | 20000 | Yes |

- Urban Water Distribution: Core pipelines for municipal potable water and fire-fighting water loop, exploiting high pressure and corrosion-resistant characteristics of cast iron water main pipe.

- Industrial Conveyance: Cast ductile iron pipe and cast iron conduit for transfer of chemicals, raw materials, and mechanical slurry at factories, refineries, and mining sites.

- Drainage & Sewer Systems: Cast drain pipe and cast iron drain pipes for sale used in gravity or forced main lines; especially popular for their lifespan (over 80 years in typical use).

- HVAC and Heating: Cast iron heating pipes ensure reliability for central heating setups, resisting high temperatures with low expansion coefficients.

- Telecom & Electrical Infrastructure: Custom cast iron conduit protects sensitive cabling in harsh environmental conditions.

| Nominal Size (DN) | Outside Diameter (mm) | Standard |

|---|---|---|

| DN100 | 110 | ISO 2531 / EN 545 |

| DN150 | 160 | ISO 2531 / EN 545 |

| DN200 | 210 | ISO 2531 / EN 545 |

| DN400 | 419 | ISO 2531 / EN 545 |

| DN600 | 630 | ISO 2531 / EN 545 |

| DN1200 | 1220 | ISO 2531 / EN 545 |

Knowing the cast iron outside diameter facilitates precise engineering design and seamless product integration.

The journey of cast iron water main pipe from historical city grids to today’s high-pressure, specialized networks showcases its enduring relevance. Thanks to robust R&D and technologically advanced production by leaders like Shijiazhuang Casiting Trading Co., Ltd., clients can access not only globally standardized products—such as centrifugally cast iron pipe, cast iron conduit, and cast iron heating pipes—but also bespoke casting solutions like Inblock Cast Service, Monoblock Cast Service, Integral Casting Service, Made in Cast Steel. The future points to more sustainable, longer-lasting, and technically superior piping infrastructure across the globe.

For detailed technical specifications, support, or procurement inquiries about cast iron water main pipe and related products, contact Shijiazhuang Casiting Trading Co., Ltd. via email or telephone.