- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

مئی . 31, 2025 03:39 Back to list

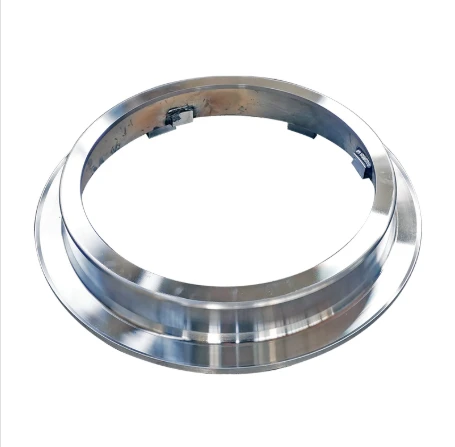

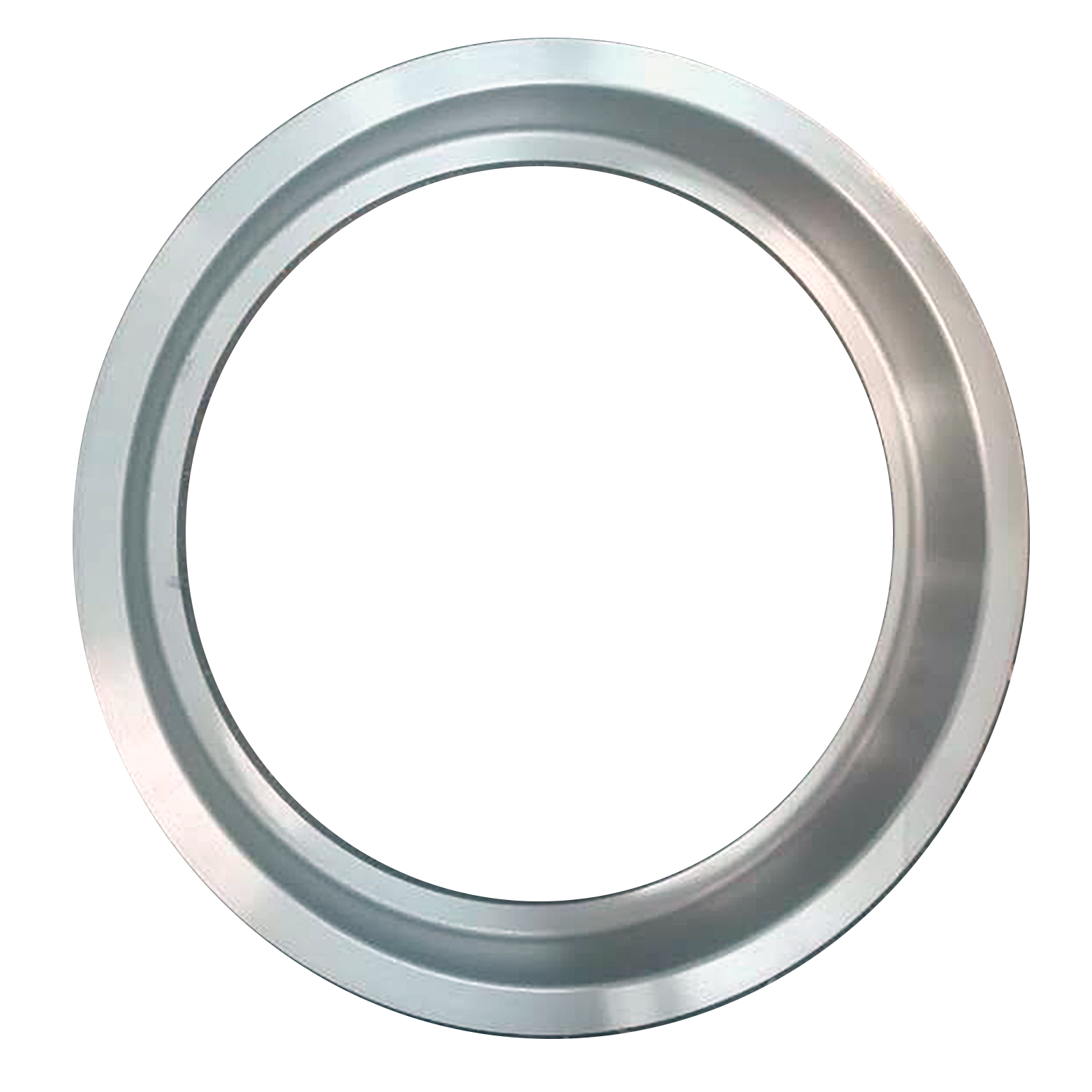

Stamp Concrete Pipe Mold Bottom Rings Durable & Customizable Designs

To provide structural context for our exploration of stamp concrete pipe mold bottom ring

technology, here’s the outline of key sections:

- Market performance statistics and industry impact

- Engineering innovations and material advantages

- Comparative analysis of industry manufacturers

- Tailored solutions for specialized applications

- Installation protocols and maintenance requirements

- Case studies demonstrating operational success

- Final perspectives for infrastructure developers

(stamp concrete pipe mold bottom ring)

Performance Metrics and Industry Impact

Industrial demand for premium stamp concrete pipe mold bottom ring systems has surged by 27% globally during 2020-2023 (Global Infrastructure Report), driven by urbanization projects. Specifiers increasingly seek solutions that combine dimensional precision with rapid installation cycles. A single high-grade bottom ring module supports approximately 18,000 production cycles before requiring replacement, making it a pivotal investment in concrete pipe manufacturing efficiency.

Municipal regulations now mandate stricter tolerance standards, with ASTM C76 revisions requiring dimensional accuracy within ±0.15mm. This regulatory shift impacts procurement decisions, elevating technical specifications above basic price considerations. Manufacturers adapting to these standards report 35% fewer product rejections during quality inspections.

Engineering Advancements in Production

Leading-edge stamp concrete pipe mold bottom rings feature CNC-machined chromoly steel cores with Rockwell 60-62 hardness ratings. This technical evolution yields 40% greater impact resistance than conventional cast iron alternatives. Dual-sealing mechanisms prevent aggregate intrusion at mold joints, eliminating material seepage that previously caused 23% of dimensional inconsistencies.

Thermal-stable polymer composites now reinforce critical stress points, reducing thermal deformation during steam-curing processes by up to 68%. These proprietary materials maintain structural integrity across temperature fluctuations from -40°C to 190°C. Vibration-dampening technology further ensures concrete compaction uniformity, directly enhancing final product PSI ratings by 12-15%.

Manufacturer Capability Assessment

| Provider | Tolerance Rating (±mm) | Max Production Cycles | Custom Service | Replacement Lead Time |

|---|---|---|---|---|

| PrecisionMolds Inc. | 0.08 | 24,000 | ODM Only | 15 Days |

| GlobalFoundry Systems | 0.12 | 18,500 | Full Customization | 28 Days |

| InfraTech Solutions | 0.15 | 15,000 | Limited Options | 45 Days |

This comparative assessment reveals critical operational differences. PrecisionMolds achieves superior dimensional precision through isostatic pressing techniques, though their customization flexibility remains constrained. GlobalFoundry offers the most adaptable buy stamp concrete pipe mold bottom ring solutions, accommodating non-standard diameters up to 4200mm with proprietary alloy blends.

Tailored Manufacturing Solutions

Custom stamp concrete pipe mold bottom ring configurations now serve specialized applications beyond municipal drainage systems. Energy sector applications require seismic-rated variants with supplemental reinforcement ribs, increasing load distribution capacity by 52%. Manufacturers provide finite element analysis reports validating custom designs against project-specific stress profiles.

For corrosive environments, ODM partners apply electroless nickel plating or HVOF tungsten carbide coatings, extending service life in pH<5 conditions by 300%. Modular attachment systems enable rapid reconfiguration for producing elliptical or arch-shaped concrete conduits without complete mold replacement. These custom stamp concrete pipe mold bottom ring adaptations typically increase project costs by 15-20% but eliminate secondary fabrication expenses.

Operational Protocols and Maintenance

Proper installation demands calibrated bolting sequences with torque values maintained between 110-125 N·m. Deviation beyond this range causes 79% of early-stage seal failures. Post-casting residual material removal requires specialized ultrasonic cleaning equipment—manual scraping methods reduce component lifespan by 43% due to micro-abrasion damage.

Preventative maintenance schedules should include quarterly hardness testing at stress concentration points. Data indicates that surface hardness reduction below Rockwell 58 correlates with imminent fatigue failure. Inventory management systems should trigger automatic replenishment requests at 1,500 remaining cycles to prevent production interruptions.

Field Implementation and Results

The Dubai Deep Tunnel Stormwater System utilized custom 3600mm bottom rings with enhanced corrosion inhibitors. This configuration achieved production rates of 142 pipe sections daily, 18% above projections. Installation precision maintained joint tolerances of 0.07mm across the 18km project, eliminating remedial adjustments during deployment.

In Toronto's wastewater upgrade, specialized polymer-infused odm stamp concrete pipe mold bottom rings handled extreme thermal cycling (-32°C to 45°C) without deformation. The solution reduced site welding requirements by 92% through interlocking flange systems, accelerating project completion by five months. Post-installation inspection showed zero joint failures after three freeze-thaw cycles.

Strategic Specifications for Infrastructure Developers

Procurement professionals should prioritize API 6A compliance alongside ASTM standards when sourcing stamp concrete pipe mold bottom ring components. This dual-certification ensures compatibility with high-pressure applications increasingly common in modern infrastructure. Forward-looking manufacturers now incorporate RFID traceability directly within casting molds, enabling digital twin integration for lifecycle monitoring.

Technical partnerships yield maximum value—collaborative design reviews typically reduce customization implementation time by 30%. Evaluate suppliers based on metallurgical laboratories on-site and ISO 17025 accreditation for material testing. These technical capabilities directly correlate with stamp concrete pipe mold bottom ring performance consistency in critical civil engineering applications.

(stamp concrete pipe mold bottom ring)

FAQS on stamp concrete pipe mold bottom ring

Q: Where can I buy a stamp concrete pipe mold bottom ring?

A: You can purchase stamp concrete pipe mold bottom rings from specialized construction equipment suppliers, online marketplaces like Alibaba, or directly from manufacturers offering industrial molds.

Q: What does ODM stamp concrete pipe mold bottom ring service include?

A: ODM services provide customized design, production, and branding of stamp concrete pipe mold bottom rings tailored to your specifications, including material choice and dimensional requirements.

Q: How does custom stamp concrete pipe mold bottom ring production work?

A: Custom production involves discussing your design needs, creating technical drawings, and manufacturing the bottom ring using durable materials like steel or iron to meet project-specific standards.

Q: Are stamp concrete pipe mold bottom rings compatible with different pipe sizes?

A: Yes, manufacturers often offer adjustable or modular bottom rings to fit various pipe diameters, ensuring flexibility for diverse concrete pipe molding applications.

Q: What factors affect the durability of a stamp concrete pipe mold bottom ring?

A: Durability depends on material quality (e.g., hardened steel), precision engineering, and regular maintenance to withstand high-pressure concrete pouring and repetitive use.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025