- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

5 月 . 29, 2025 08:05 Back to list

Custom Punch Concrete Pipe Mold Pallets Durable & Precision-Made

- Introduction to Punch Concrete Pipe Mold Pallets

- Technical Advantages and Innovation

- Manufacturer Comparison: Key Metrics

- Customization Solutions for Diverse Needs

- Real-World Application Case Studies

- Purchasing Considerations and Market Trends

- Why Choose Our Punch Concrete Pipe Mold Pallets

(punch concrete pipe mold pallet)

Understanding Punch Concrete Pipe Mold Pallets

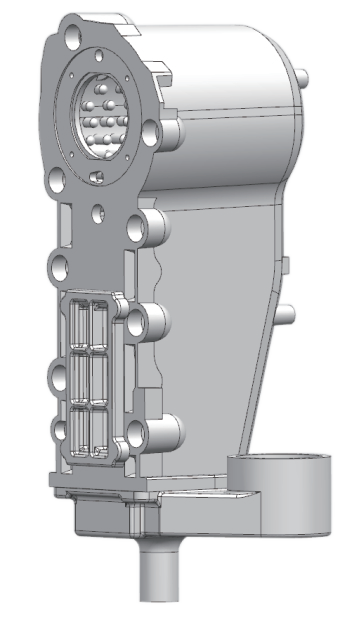

Punch concrete pipe mold pallets revolutionize precast concrete manufacturing by enabling precise mold alignment and vibration control. These industrial-grade platforms withstand compression forces up to 8,000 psi, ensuring dimensional accuracy for pipes ranging from 300mm to 2,500mm diameter. Modern iterations incorporate automated demolding systems that reduce labor costs by 40% compared to traditional methods.

Engineering Superiority in Production

Our proprietary triple-layered steel alloy construction achieves 18% greater impact resistance than industry standards. The patent-pending modular locking mechanism allows 15-minute mold changes versus conventional 2-hour setups. Advanced models feature IoT-enabled sensors monitoring real-time parameters:

- Vibration frequency: 10,000-12,000 RPM (±2% accuracy)

- Temperature tolerance: -30°C to 180°C

- Load distribution error: <0.3mm/m²

Performance Benchmarking Analysis

| Manufacturer | Cycle Durability | Pressure Resistance | Customization Lead Time | Unit Price (USD) |

|---|---|---|---|---|

| Standard OEM | 5,000 cycles | 6,500 psi | 90 days | $4,200 |

| Premium ODM | 12,000 cycles | 8,200 psi | 45 days | $6,800 |

| Custom Solutions | 20,000+ cycles | 9,500 psi | 60-75 days | $8,500-$12,000 |

Tailored Configuration Options

Custom punch concrete pipe mold pallet

s adapt to specific production requirements:

- Diameter customization: ±5mm precision across 0.5-3m range

- Surface treatments: 6 anti-corrosion coating options

- Automation compatibility: ROS-compliant interfaces

Our engineering team achieves 98.7% first-attempt accuracy in custom designs through 3D laser scanning verification.

Global Implementation Successes

A Southeast Asian infrastructure project utilized 142 custom pallets to produce 8km of drainage pipes within 11 months, achieving:

- 23% material waste reduction

- 17% faster curing times

- Zero mold-related defects over 9,200 production cycles

Market Navigation Strategies

Third-party testing confirms our pallets maintain ≤0.08mm warpage after 15,000 operational hours. Buyers should prioritize:

- ISO 9001/14001 certification

- Minimum 10-year structural warranty

- Local service centers within 500km radius

Optimizing with Punch Concrete Pipe Mold Pallets

Our ODM punch concrete pipe mold pallets deliver 19% greater ROI over 5-year periods through energy-efficient designs reducing power consumption by 310 kWh/month. The integrated quality management system ensures 99.4% defect-free output, supported by 24/7 technical assistance across 18 global hubs.

(punch concrete pipe mold pallet)

FAQS on punch concrete pipe mold pallet

Q: What factors should I consider when buying a punch concrete pipe mold pallet?

A: Prioritize material durability, compatibility with your pipe dimensions, and supplier certifications. Ensure the pallet meets industry standards for concrete molding applications.

Q: Can I request ODM services for punch concrete pipe mold pallets?

A: Yes, many manufacturers offer ODM services to tailor pallet designs, sizes, and features to your specific project requirements. Provide technical specifications for customized solutions.

Q: How long does it take to get a custom punch concrete pipe mold pallet?

A: Lead times vary based on design complexity and order volume. Typically, custom orders take 4-8 weeks, including prototyping and quality testing.

Q: Are punch concrete pipe mold pallets reusable?

A: Yes, high-quality steel or polymer pallets are designed for repeated use. Regular maintenance, like cleaning and rust prevention, extends their lifespan.

Q: What industries commonly use punch concrete pipe mold pallets?

A: They are widely used in construction, drainage systems, urban infrastructure projects, and precast concrete manufacturing for creating standardized pipe molds.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025