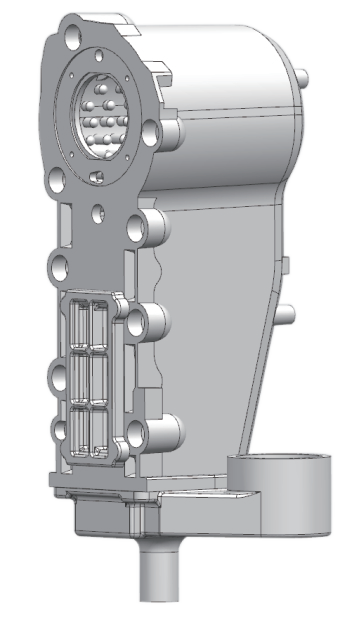

Hydraulic Coupler, Pump Wheel, Gland, End Cap, Aluminum Casting Service, Made in china

Brief Introduction

Cast aluminum is a kind of casting technology, that the pure aluminum or aluminum alloy ingot is prepared according to the standard composition ratio, and heated to turn it into a liquid or molten aluminum alloy, and then pour the aluminum liquid or molten aluminum alloy into a professional mold or cavity and cooled to form aluminum parts of the required shape.

The aluminum used in cast aluminum is called: cast aluminum alloy.

Commonly used aluminum casting technologies are sand casting, metal mold casting, investment casting, pressure casting, lost foam casting, low-pressure casting, differential pressure casting, squeeze casting, vacuum suction casting, centrifugal casting, precision casting, permanent mold casting, etc.

At present, our casting aluminum technology is Low-Pressure Sand Casting. Our annual productivity is about 600 tons.Our current casting aluminum products is as follows:

|

|

Pump impeller for coal minging equipment |

|

End cover for west-east natural gas transmission equipment |

Pump impeller for coal mining equipment |

Write your message here and send it to us

Products categories