- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ян. . 13, 2025 11:31 Back to list

src concrete pipe mold/mould pallet

When it comes to the manufacturing and construction industries, the significance of selecting the right tools and equipment cannot be overstated. One of the pivotal components in concrete production is the concrete pipe mold, often used in conjunction with a mold pallet. The synergy between concrete pipe molds and mold pallets underscores not only the quality of the final product but also the efficiency of the production process. Here, we delve into the essentials of concrete pipe molds and mold pallets, while establishing their paramount importance to any construction endeavor.

Expertise in this domain is necessary for understanding the nuanced interactions between molds and pallets. For instance, an expert will recognize how the temperature and humidity conditions can affect the curing process and adjust the timing and materials accordingly. They will also advise on regular maintenance practices, such as cleaning and occasional calibration checks, to extend the utility of both the mold and the pallet. This professional insight is pivotal for companies seeking to improve production efficiencies and reduce downtime. Authoritativeness in the realm of concrete pipe molds and mold pallets is often exemplified by adherence to international quality standards. Whether adhering to ASTM, ISO, or CE standards, certified products often undergo rigorous testing to ensure they deliver not only on functionality but safety. Producers and manufacturers that invest in acquiring these certifications demonstrate their commitment to quality and reliability, often becoming industry leaders. Trustworthiness stems from the relationship between the provider and the client. A trustworthy supplier of concrete pipe molds and mold pallets will offer warranties or service guarantees, reflecting confidence in their products. Furthermore, transparency in material sourcing and production methods enhances a company's credibility, empowering clients to make informed decisions based on detailed product knowledge. Overall, the interplay between concrete pipe molds and mold pallets is a keystone in the construction industry, anchoring effective production through durability, precision, and expert craftsmanship. Embracing products designed with these qualities ensures long-term success and reliability, reinforcing a company’s reputation as a leader in producing high-quality concrete solutions.

Expertise in this domain is necessary for understanding the nuanced interactions between molds and pallets. For instance, an expert will recognize how the temperature and humidity conditions can affect the curing process and adjust the timing and materials accordingly. They will also advise on regular maintenance practices, such as cleaning and occasional calibration checks, to extend the utility of both the mold and the pallet. This professional insight is pivotal for companies seeking to improve production efficiencies and reduce downtime. Authoritativeness in the realm of concrete pipe molds and mold pallets is often exemplified by adherence to international quality standards. Whether adhering to ASTM, ISO, or CE standards, certified products often undergo rigorous testing to ensure they deliver not only on functionality but safety. Producers and manufacturers that invest in acquiring these certifications demonstrate their commitment to quality and reliability, often becoming industry leaders. Trustworthiness stems from the relationship between the provider and the client. A trustworthy supplier of concrete pipe molds and mold pallets will offer warranties or service guarantees, reflecting confidence in their products. Furthermore, transparency in material sourcing and production methods enhances a company's credibility, empowering clients to make informed decisions based on detailed product knowledge. Overall, the interplay between concrete pipe molds and mold pallets is a keystone in the construction industry, anchoring effective production through durability, precision, and expert craftsmanship. Embracing products designed with these qualities ensures long-term success and reliability, reinforcing a company’s reputation as a leader in producing high-quality concrete solutions.

Share

Pervious:

Latest news

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

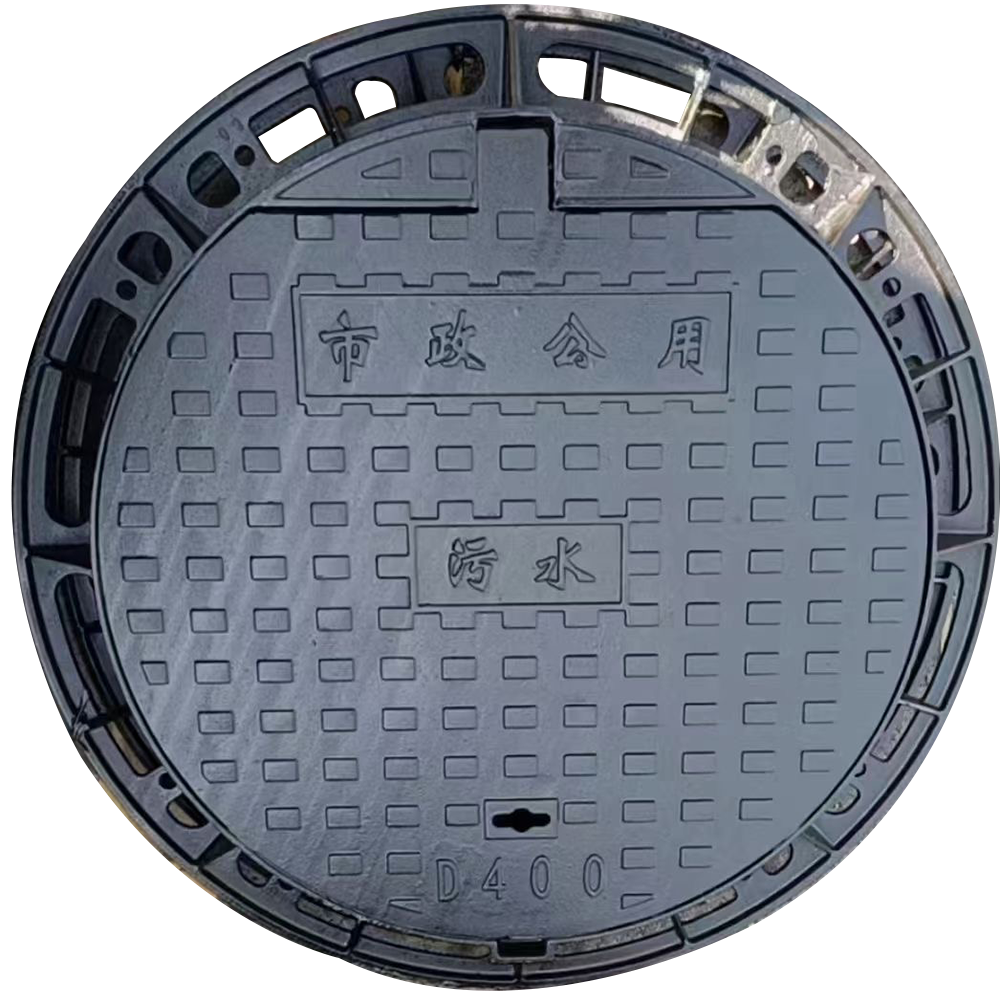

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025