1. Industry Overview and Trends in Cast Iron Water Main Pipe

Cast iron water main pipe systems, historically utilized since the 19th century, are now facing modernization with upgraded material science, stricter inspection standards (ISO 2531, EN 877, ANSI/AWWA C110/A21.10), and eco-friendly anti-corrosion technologies. The adoption of centrifugally cast iron pipe processes, as opposed to traditional sand casting, has improved wall thickness consistency and increased pressure ratings.

- Material Innovation: Emergence of silicon-iron and ductile iron compositions, offering higher strength and impact resistance.

- Production Automation: CNC machining and robotic lining technology for precision joints and interior coatings.

- Global Standardization: Growing enforcement of ISO/FDA water safety and anti-corrosion standards for potable and industrial water systems.

- Market Shift: Increased demand for energy-efficient heating and cost-effective drainage solutions, leading to hybrid systems combining cast iron conduit and plastic lining.

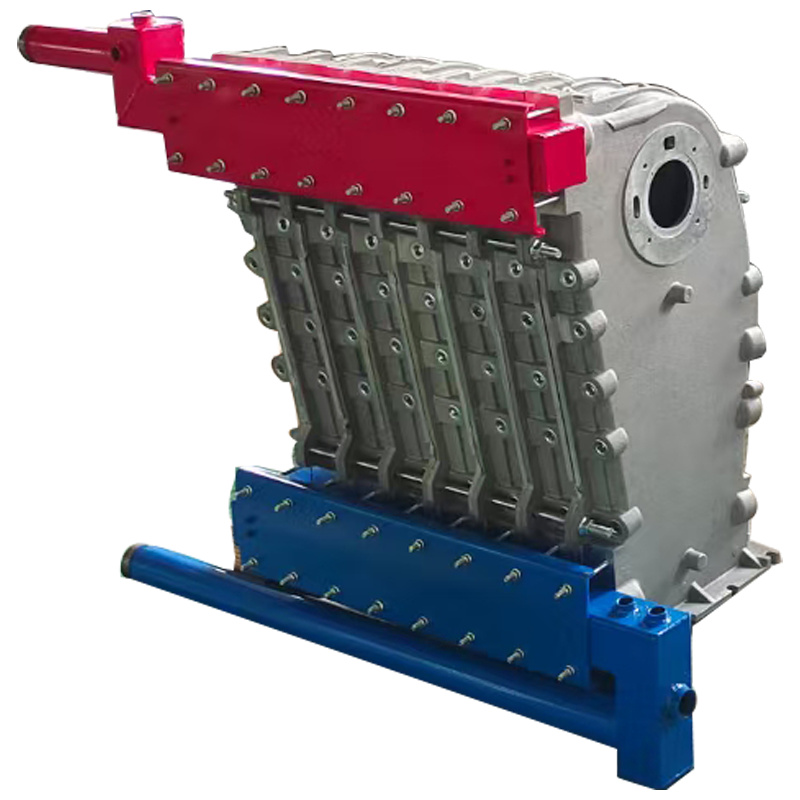

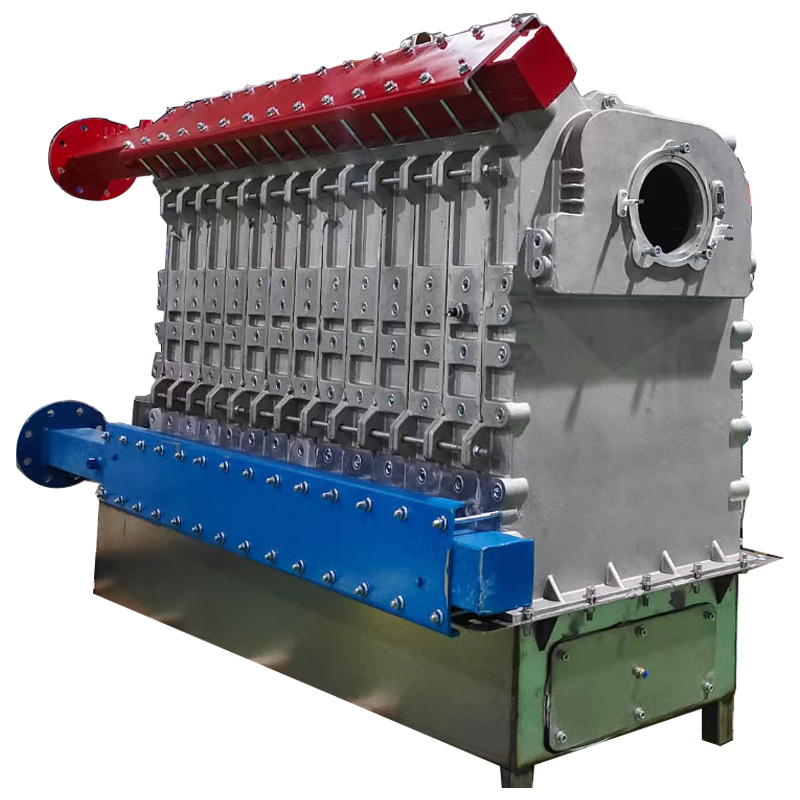

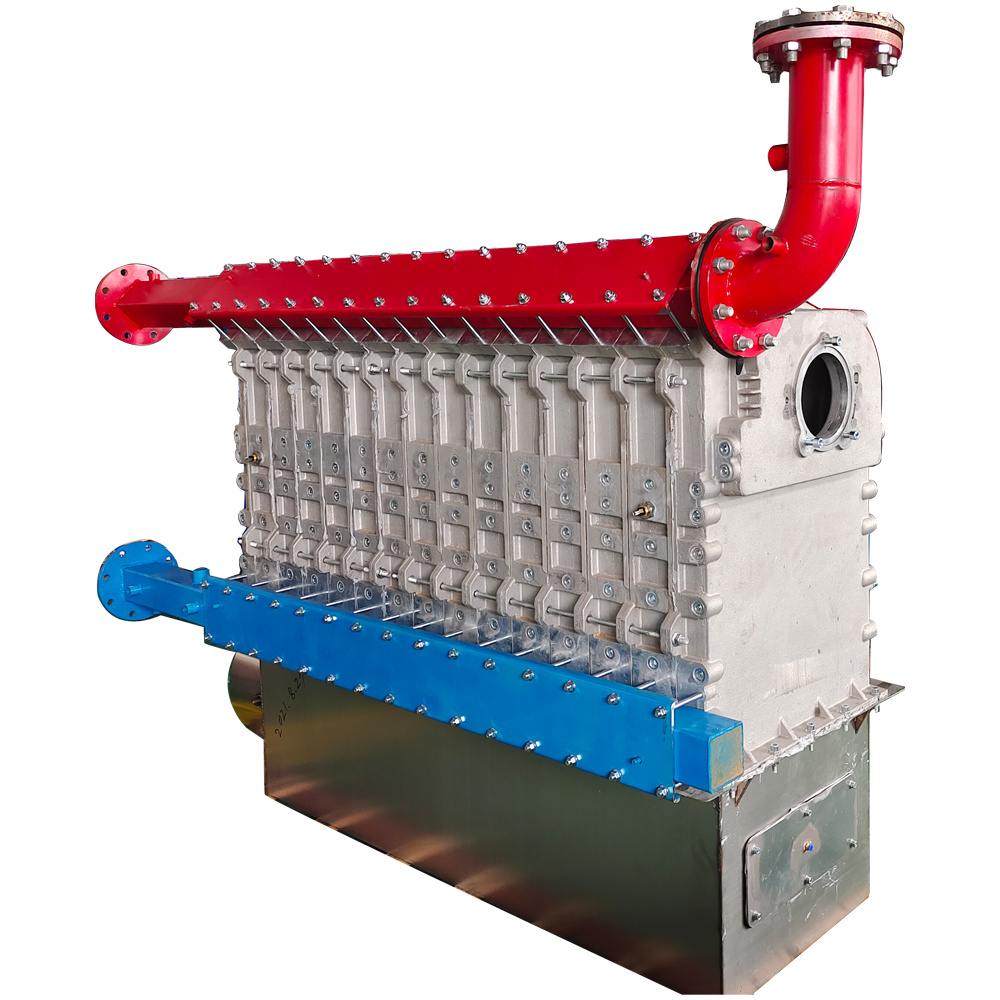

2. Product Information: Fully Premixed Cast Silicon Aluminum Heat Exchanger for Commercial Boiler (M type)

As a leading example of innovation, the Fully Premixed Cast Silicon Aluminum Heat Exchanger for Commercial Boiler (M type) (Product Link) sets new industry benchmarks for energy transfer efficiency, anti-corrosion performance, and mechanical durability.

- Material: Silicon-aluminum alloy, offering thermal conductivity >184 W/m·K and corrosion resistance suitable for condensing gas boilers.

- Manufacturing: Advanced investment casting and CNC finishing ensures micro-scale smoothness for turbulent flow optimization.

- Testing: Each unit is pressure-tested up to 10 MPa and adheres to ISO 9001:2015 and EN15502 standards.

- Lifetime: Designed for 25+ years of operation in harsh, cyclic environments.

- Typical Application: Commercial HVAC, district heating, recuperative energy systems.

3. Manufacturing Process of Cast Iron Water Main Pipe (With Flow Diagram)

Iron, Carbon, Silicon, Alloying Agents

Induction Furnace at 1400–1500°C

Uniform Wall Thickness, Dense Structure

Annealing/Quenching for Ductility

ISO/ANSI Dimensional Check, Hydrostatic Test

Epoxy/Bitumen Lining, Fiber Wrapping

4. Typical Technical Parameters of Cast Iron Water Main Pipes

| Parameter | Centrifugally Cast Iron Pipe | Ductile Cast Iron Pipe | Cast Iron Drain Pipe |

|---|---|---|---|

| Standard | ISO 2531 / EN 545 | ISO 2531 / EN 598 | EN 877 |

| Outside Diameter (mm) | 80–1000 | 80–2200 | 50–400 |

| Wall Thickness (mm) | 6.0–13.8 | 5.0–15.3 | 3.5–10 |

| Working Pressure (Bar) | PN10–PN25 | PN10–PN40 | PN5–PN10 |

| Typical Application | Water main, Fire line | Municipal Water, Gas, Sewer | Drainage, Waste |

| Coating | Cement lining/Bitumen | Zinc/PU/Epoxy/Bitumen | Epoxy/Polyester/Bitumen |

| Expected Service Life (years) | 50–75 | 80–100 | 50–60 |

5. Data Visualization: Heat Exchanger Performance

6. Application Scenarios & Real-world Case Studies

Cast iron water main pipe products are indispensable in multiple sectors:

- Municipal Water Transmission: High-durability and anti-corrosive cast iron outside diameter pipes for potable water and fire safety mains.

- Industrial Drainage: Using cast drain pipe and cast iron drain pipes for sale in petrochemical process waters and effluent control.

- District Heating: Cast iron heating pipes provide rapid heat transfer and pressure stability in urban and industrial heating networks.

- Telecom/Gas Infrastructure: Heavy-duty cast iron conduit ensures electromagnetic shielding and crush resistance for crucial cable and gas lines.

- Custom Solutions: Large-diameter, custom-coated pipes specified by leading OEMs for marine and offshore water systems.

In 2022, a major Eastern European city replaced over 18 km of legacy main lines with cast iron water main pipe, achieving a 34% reduction in maintenance costs and 55% fewer leak incidents according to local utility records. Most pipes utilized were ductile iron in compliance with ISO 2531.

7. Manufacturer Benchmarking: Cast Iron Water Main Pipe Market Comparison

| Brand / Supplier | Main Material | Size Range (mm OD) | Certifications | Warranty | Specialization |

|---|---|---|---|---|---|

| Casiting | Silicon-aluminum / Ductile iron | 80–1000 | ISO 2531, EN 545, EN 877 | 25–50 years | Custom industrial heat exchanger & water mains |

| Saint-Gobain PAM | Ductile cast iron | 80–2200 | ISO, ANSI, WRAS | 30 years | Drinking water & gas solutions |

| US Pipe | Ductile cast iron | 100–2000 | AWWA, NSF | 50 years | Municipal/Fire water |

| Mueller Water Products | Ductile iron | 100–1200 | ANSI, ISO | 25–40 years | Water & wastewater |

8. Customization, Delivery, and Support

- Support for custom cast iron outside diameter specs from DN80–DN2200 mm and wall thickness up to 21 mm.

- Internal cement or epoxy lining, hot-dip bitumen or polyurethane outside, MEGA-flange options.

- Standard delivery: 20–60 days depending on order volume; urgent production in as fast as 14 days on select SKUs.

- Warranty: 25+ years anti-corrosion guarantee, 12 months on valves and fabricated parts.

- Customer support: 24/7 technical hotline, on-site installation/inspection available worldwide (Europe, MENA, Americas).

9. Professional FAQ on Cast Iron Water Main Pipe and Related Products

10. Why Choose Casiting for Your Cast Iron Water Main Pipe and Heat Exchanger Needs?

- ISO 2531-compliant, third-party tested products for guaranteed safety and quality.

- 25+ years of industry experience, extensive OEM and EPC references worldwide.

- Integrated CNC and automated casting lines achieve tolerance ±0.15mm, ensuring interchangeability with global municipal systems.

- Technical support in 4 major languages, fast-response quotation and logistics teams.

Contact Casiting’s professional team for tailored support.

[1] "Cast iron pipes for water and sewage: Properties, Applications, Trends." Water World Magazine, 2023. Read more

[2] EN 877: Cast iron pipes and fittings for drainpipes – European Standards, CEN. Official standard

[3] AWWA C110/A21.10– American Water Works Association: Testing and installation guidance. AWWA Resources

[4] "Performance of ductile iron water pipes in seismic regions" – Pipeline and Gas Journal, Vol. 249, No.3, 2022.

[5] Industry discussion board: "Cast Iron or Ductile for Mains?" Engineering Tips Forum