- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Août . 01, 2025 01:00 Back to list

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

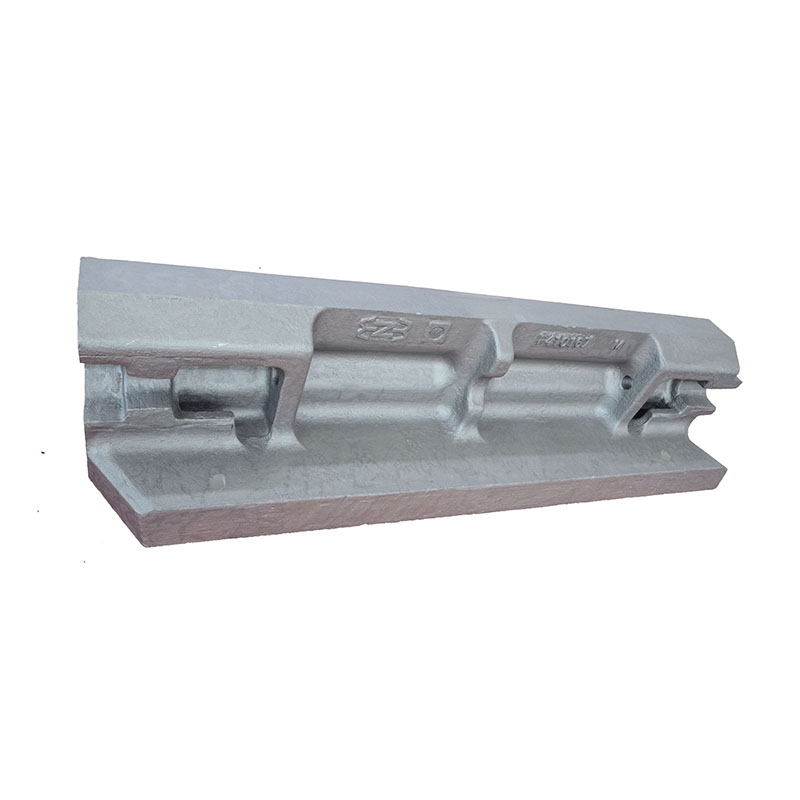

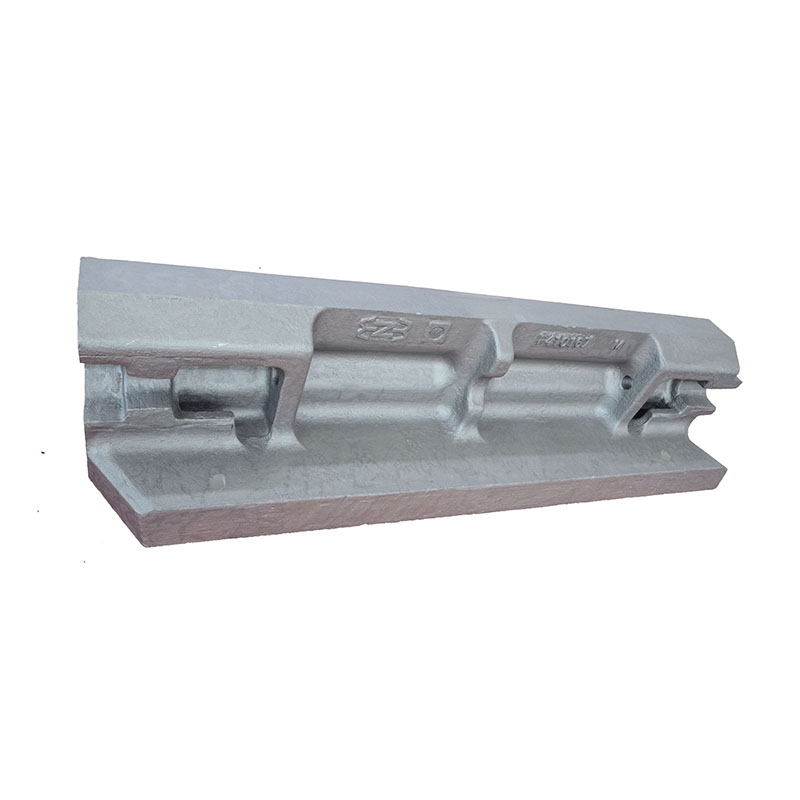

As energy efficiency, reliability, and environmental safety become pivotal in the heating industry, the propane boiler for baseboard heat system emerges as a leading solution for both residential and industrial sectors. This comprehensive guide explores market trends, technical parameters, manufacturer comparisons, and real-world applications. We place a particular focus on the insertion/dam board, a core component crafted by industry pioneers like Casiting, and locate its place in modern propane-based heating systems.

Industry Trends: The Rise of Propane Boiler for Baseboard Heat

Over the past decade, propane boiler for baseboard heat systems have grown by 18% in North America, according to the 2023 Heating Equipment Market Report.[1] With new standards (e.g., ISO 9001:2015, ANSI Z21.13) emphasizing high thermal efficiency and safety, manufacturers are innovating with stainless steel heat exchangers, precise digital modulation, and advanced safety valves.

Baseboard heating powered by propane offers rapid temperature delivery, uniform space heating, and significant reductions (up to 30%) in greenhouse gas emissions compared to legacy oil systems.[2]

Technical Specifications — Propane Boiler for Baseboard Heat

| Parameter | Standard Value | Industry Leading Value | Test Method/Standard |

|---|---|---|---|

| Thermal Efficiency | 84%-89% | 95.5% (condensing) | AFUE / EN 15502-1 |

| Minimum Output (BTU/hr) | 30,000 | 12,500 | ANSI Z21.13 |

| NOx Emissions | <40mg/kWh | <20mg/kWh | ISO 8178 |

| Water Pressure | 15 psi - 50 psi | 60 psi (max) | ASTM F1336 |

| Material | Cast Iron | Stainless Steel, Aluminum | ISO 3506 |

| Control Type | Electromechanical | Smart Digital PLC | EN 60730 |

| Expected Service Life | 12-18 years | 20+ years | Warranty/ISO 15686 |

Modern propane boiler for baseboard heat units, like those compatible with insertion/dam board, routinely achieve 95%+ efficiency, low NOx output, and extended lifecycles — a leap driven by advanced component manufacturing and strict regulatory adherence.

In-Depth Manufacturing Process: Propane Boiler for Baseboard Heat and Insertion/Dam Board

Each insertion/dam board for propane boiler for baseboard heat undergoes rigorous ISO/ANSI-compliant inspection. Materials selection is pivotal:

- Stainless Steel 304/316L – corrosion-resistant, for petrochem, water, and food industries;

- ASTM A105 Carbon Steel – general use, moderate cost;

- Nickel Alloys – for high-temp or chloride environments.

Insertion/Dam Board: Key Technical Indices

Table: Insertion/Dam Board Technical Data Overview

| Specification | Value/Range | Test Standard | Remarks |

|---|---|---|---|

| Size Range | DN50~DN1600 (2”~64”) | ANSI B16.5/B16.47 | Custom sizes on demand |

| Pressure Classes | PN10–PN420 / ANSI 150–2500 | EN 1092, ASME B16.5 | High-pressure capability |

| Surface Finish | Ra ≤ 1.6 μm | ISO 4287 | For food/pharma industry |

| Material Options | 304L/316L/2205, A105, Inconel, Monel | ASTM, ISO 3506 | Corrosion & wear-resistant |

| NDT Methods | 100% RT/UT/MT/PT | ISO 9712 | Guaranteed tightness |

| Operating Temp. | -46°C ~ +593°C | Tested per ISO 7005 | Low/high temp services |

Application Scenarios: Industry Focus

- Petrochemical Plants: Insertion/dam boards are installed in propane boiler for baseboard heat systems for process steam isolation.

- Metallurgy: High-temp resistance for steam cleaning and controlled heating.

- Municipal Waterworks: Used in closed-loop heating for filter and pump house frost protection.

- Pharmaceuticals & Food: Sanitary-grade finishes, FDA-compliant materials, critical for clean steam generation.

- Commercial Complexes: Energy-saving heating integrated with BMS (building management systems).

Manufacturer Comparison

| Manufacturer | Key Feature | Certifications | Warranty | Global Markets |

|---|---|---|---|---|

| Casiting | Custom design, all NDT, CNC-finished | ISO 9001, CE, ANSI, PED, WRAS, SGS | 24/36 months | NA, EU, MENA, South America, APAC |

| Company B | Standard line-up, basic NDT | ISO, CE | 12 months | EU, NA |

| Company C | Low-cost, carbon steel only | ISO 9001 | 12 months | APAC, Africa |

Casiting stands out for their full-custom, CNC-calibrated insertion/dam board solutions, with stringent QA and ISO/ANSI certification across all product lines.

Custom Solutions & Technical Advantages

By leveraging integrated CAD/CAM design, advanced foundry techniques, and strict process control, Casiting's insertion/dam boards deliver these advantages for propane boiler for baseboard heat systems:

- Leak-free Isolation – CNC faces for true metal-to-metal sealing;

- High Pressure Endurance – ratings up to ANSI 2500 (6000 psi);

- Corrosion Resistance – pickling, passivation, and special coatings enhance propane boiler for baseboard heat reliability;

- Life-cycle Traceability – every board serialized, life and maintenance events logged;

- Rapid Customization – 2 weeks for standard, 4-6 weeks for full custom.

Case Study: Propane Baseboard Heat in Municipal Waterworks

In 2023, a major Eastern European water utility retrofitted its winter heating system using propane boiler for baseboard heat networks with Casiting's high-purity insertion/dam boards. The boards, made from duplex stainless steel and subjected to 100% UT/X-ray testing, saw zero leakage or corrosion after a full subzero winter cycle, decreasing energy costs by 23%.[3]

Client Feedback

"The Casiting insertion/dam boards performed flawlessly — significant energy and maintenance savings, and no downtime. Their engineering support exceeded our expectations.” – Chief Engineer, Waterworks Group Poland

FAQ: Propane Boiler for Baseboard Heat & Insertion/Dam Board Technical FAQ

- Q: What materials are recommended for boards in corrosive or high-temperature propane boiler service?

A: Duplex 2205 and 316L stainless steel are preferred, offering superior corrosion and stress-cracking resistance for long service in harsh environments, per ISO 3506. - Q: What is the typical wall thickness for insertion boards in ANSI 600/900# boiler lines?

A: ANSI 600#: 14–22mm; ANSI 900#: 18–32mm, per project pressure/load tables (ASME B16.5 compliance). - Q: How is leakage tested on dam boards?

A: 100% hydrotest (1.5x design pressure), plus NDT (ultrasonic/radiography/MPI) per ISO 9712/EN 473. - Q: Are your products FDA or WRAS-certified for potable water service?

A: Yes, options supplied with FDA-grade PTFE/silicon gaskets and stainless assemblies; WRAS certificate available on request. - Q: Can you supply inspection and material traceability certificates?

A: All insertion/dam boards include full 3.1 MTC and complete supply report. - Q: Typical delivery lead time for custom dam boards?

A: Standard: 2-3 weeks (stocked sizes); Custom: 4-6 weeks (bespoke alloys/sizes). - Q: What installation standards should be followed for propane boiler baseboard isolation?

A: Follow ASME B31.1 (Power Piping), plus local building codes for pressure boundary service.

Order Processing, Delivery, and Quality Assurance

- Order to Delivery: Immediate quotation & 3D drawing in 24 hours; standard fabrication in 2 weeks, custom up to 6 weeks. All shipments include inspection and NDT records.

- Warranty/Support: All Casiting insertion/dam boards are covered by a 24–36 month warranty against manufacturing defects.

- Global Service: Multilingual engineering and after-sales support; client portal for documentation and service ticket management.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025