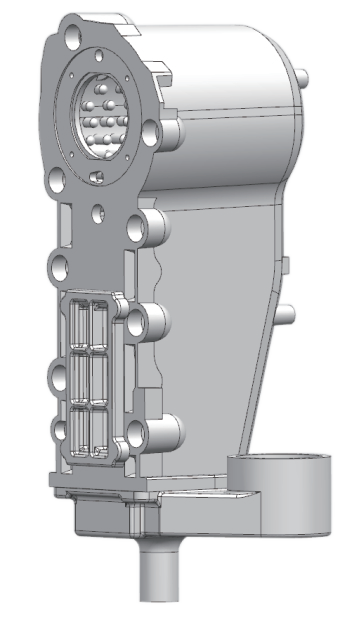

fully premixed cast silicon aluminum heat exchanger for commercial boiler(L type)

Product Description:

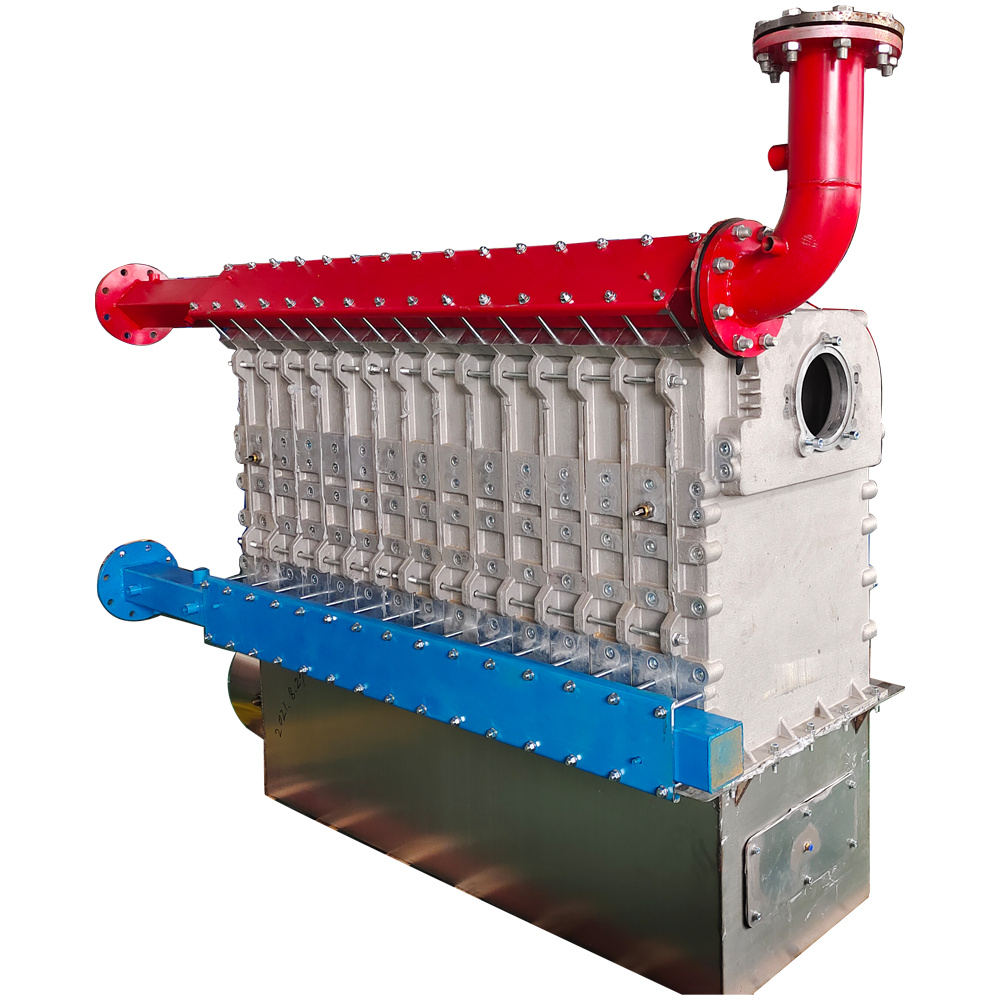

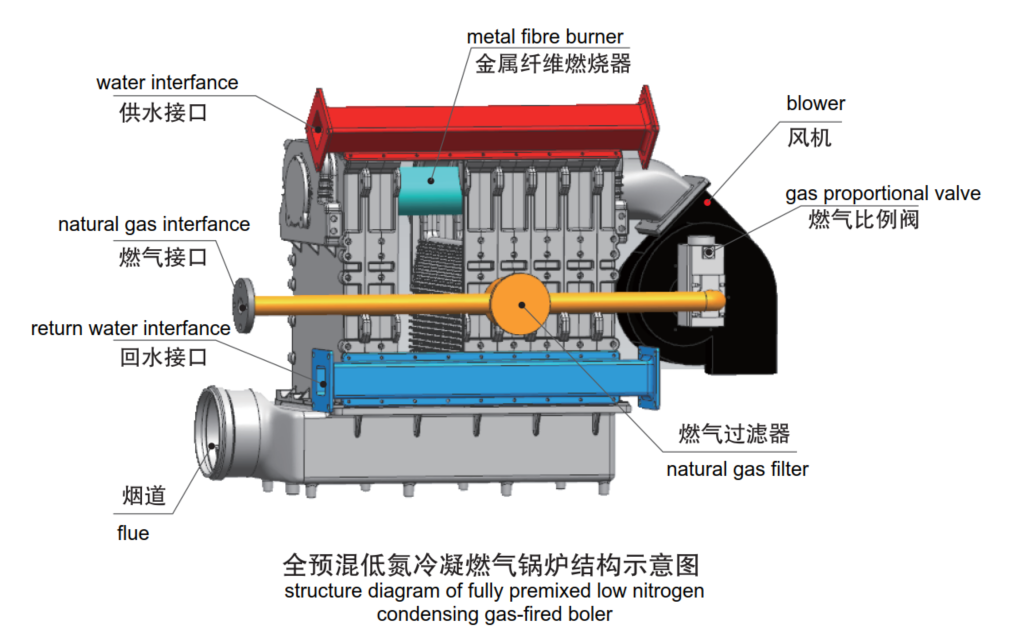

The special cast silicon-aluminum heat exchanger for commercial condensing low-nitrogen gas-fired boilers produced by Lanyan Hi-Tech is made of silicon-aluminum alloy, which has high heat exchange efficiency, corrosion resistance, durability and high hardness. It is suitable for to be the main heat exchanger of commercial condensing gas boilers with rated heat load below 2200kW.

The product adopts low pressure casting process, and the product forming rate is higher than that of similar products at home and abroad. There is a detachable cleaning port on the side. In addition, the flue gas condensation heat exchange area adopts the company's patented coating material, which can effectively prevent the accumulation of ash and carbon.

Technical Principle:

|

Blue flame high tech condensing cast silicon aluminum main heat exchanger is of cast silicon aluminum structure, integrating combustion chamber, flue and water channel. Cast aluminum heat exchanger has good corrosion resistance. In a limited volume, rib columns are used to increase the heat exchange area. The combustion chamber and water outlet are located above the main heat exchanger, and the water inlet is located at the bottom. The temperature of the water flow gradually increases from bottom to top, and the temperature of the flue gas gradually decreases from top to bottom. The reverse flow ensures that all points in the heat exchanger can carry out sufficient heat exchange, absorb the sensible heat and most of the latent heat of water vapor in the flue gas, effectively reduce the flue gas temperature, and saturate and precipitate the water vapor in the flue gas, so as to achieve the purpose of high efficiency, energy conservation and environmental protection. |

|

|

Technical Data/Model |

unit |

GARC-AL 500 |

GARC-AL 700 |

GARC-AL 1100 |

GARC-AL 1400 |

GARC-AL 2100 |

|

|

Maximum Rated Heat Input |

KW |

500 |

700 |

1100 |

1400 |

2100 |

|

|

Maximum outlet water temperature |

℃ |

80 |

80 |

80 |

80 |

80 |

|

|

Min/Max water system pressure |

Bar |

0.2/3 |

0.2/3 |

0.2/3 |

0.2/3 |

0.2/3 |

|

|

hot water supply capacity |

m3/h |

21.5 |

30.1 |

47.3 |

60.2 |

90.3 |

|

|

maximum water flow |

m3/h |

43.0 |

60.2 |

94.6 |

120.4 |

180.6 |

|

|

flue-gas temperature |

℃ |

<70 |

<70 |

<70 |

<70 |

<70 |

|

|

flue-gas temperature |

℃ |

<45 |

<45 |

<45 |

<45 |

<45 |

|

|

Maximum Condensate Displacement |

L/h |

42 |

60 |

94 |

120 |

180 |

|

|

Condensate water PH value |

- |

4.8 |

4.8 |

4.8 |

4.8 |

4.8 |

|

|

Diameter of flue interface |

mm |

250 |

250 |

250 |

300 |

400 |

|

|

Water supply and return interface size |

- |

DN100 |

DN100 |

DN100 |

DN100 |

DN100 |

|

|

Heat exchanger Overall size |

L |

mm |

528 |

632 |

941 |

1147 |

1559 |

|

W |

mm |

621 |

621 |

621 |

621 |

621 |

|

|

H |

mm |

1075 |

1075 |

1075 |

1075 |

1075 |

|

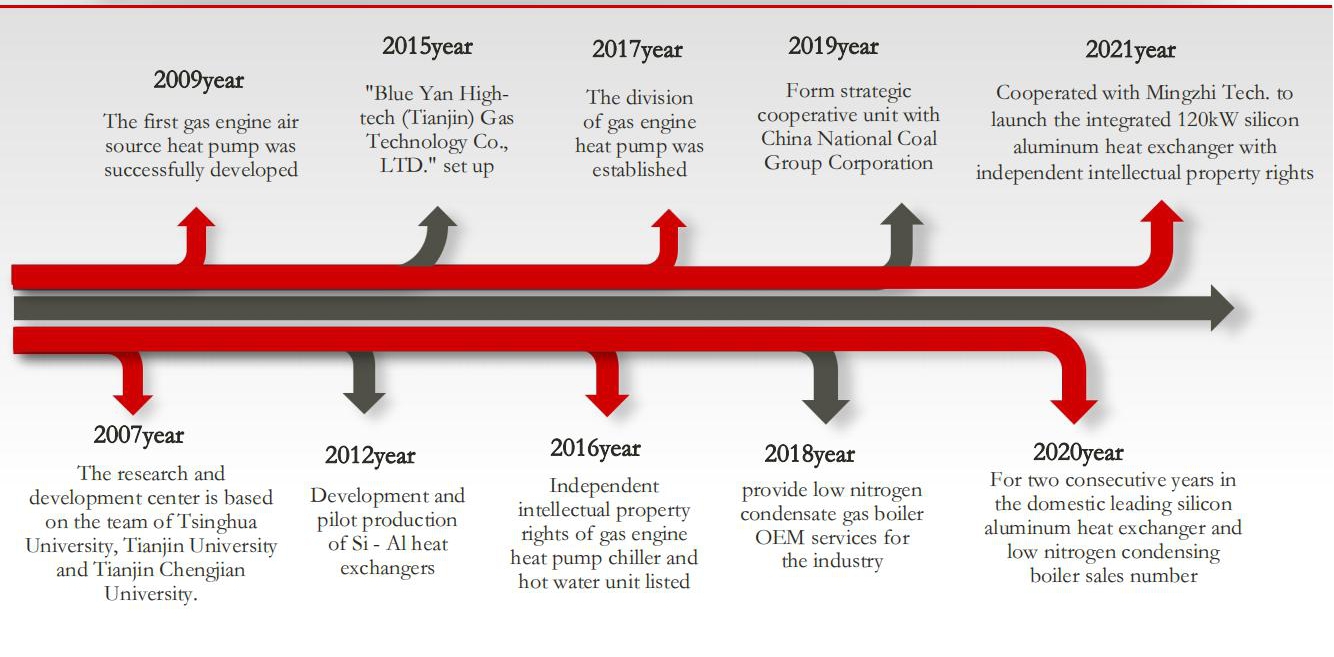

The Development and Production of the Si-Al Heat Exchanger

Inblock Cast Silicon Magnesium Aluminum Alloy Heat Exchanger

The special cast silicon aluminum heat exchanger for commercial condensing low nitrogen gas boiler is cast from silicon aluminum magnesium alloy, with high heat exchange efficiency, corrosion resistance, durability and high hardness. It is applicable to the main heat exchanger of commercial condensing gas boiler with rated heat load below 2100 kW.

The product adopts low-pressure casting process, and the molding rate of the product is higher than that of similar products at home and abroad. A removable cleaning opening is set on the side. In addition, the flue gas condensation heat exchange area adopts the company's patented coating material, which can effectively prevent ash and carbon deposition.

|

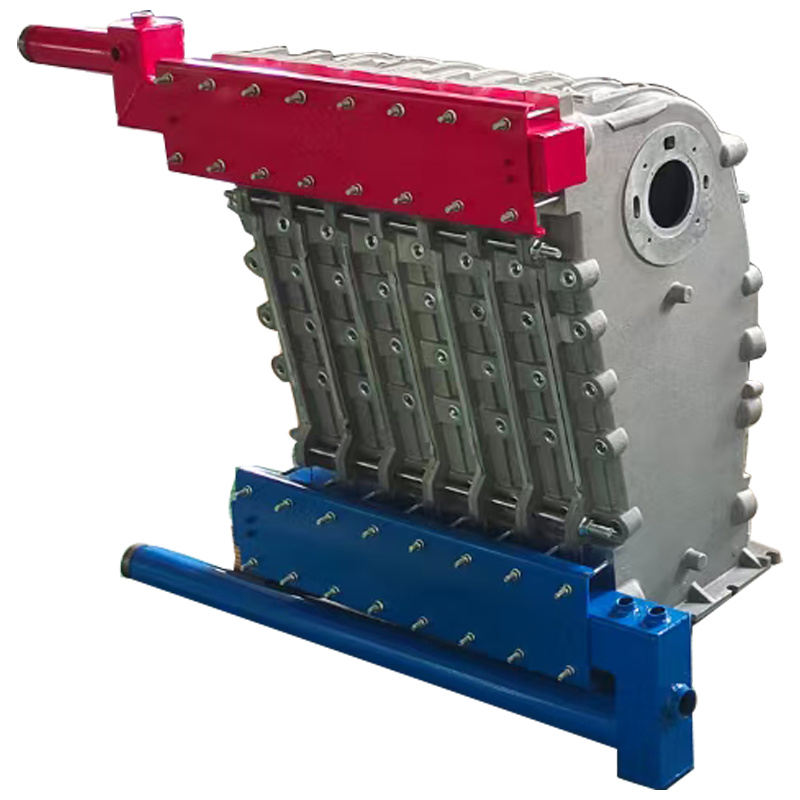

28Kw~46Kw Heat Exchanger |

60Kw~120Kw Heat Exchanger |

150Kw~350Kw Heat Exchanger |

|

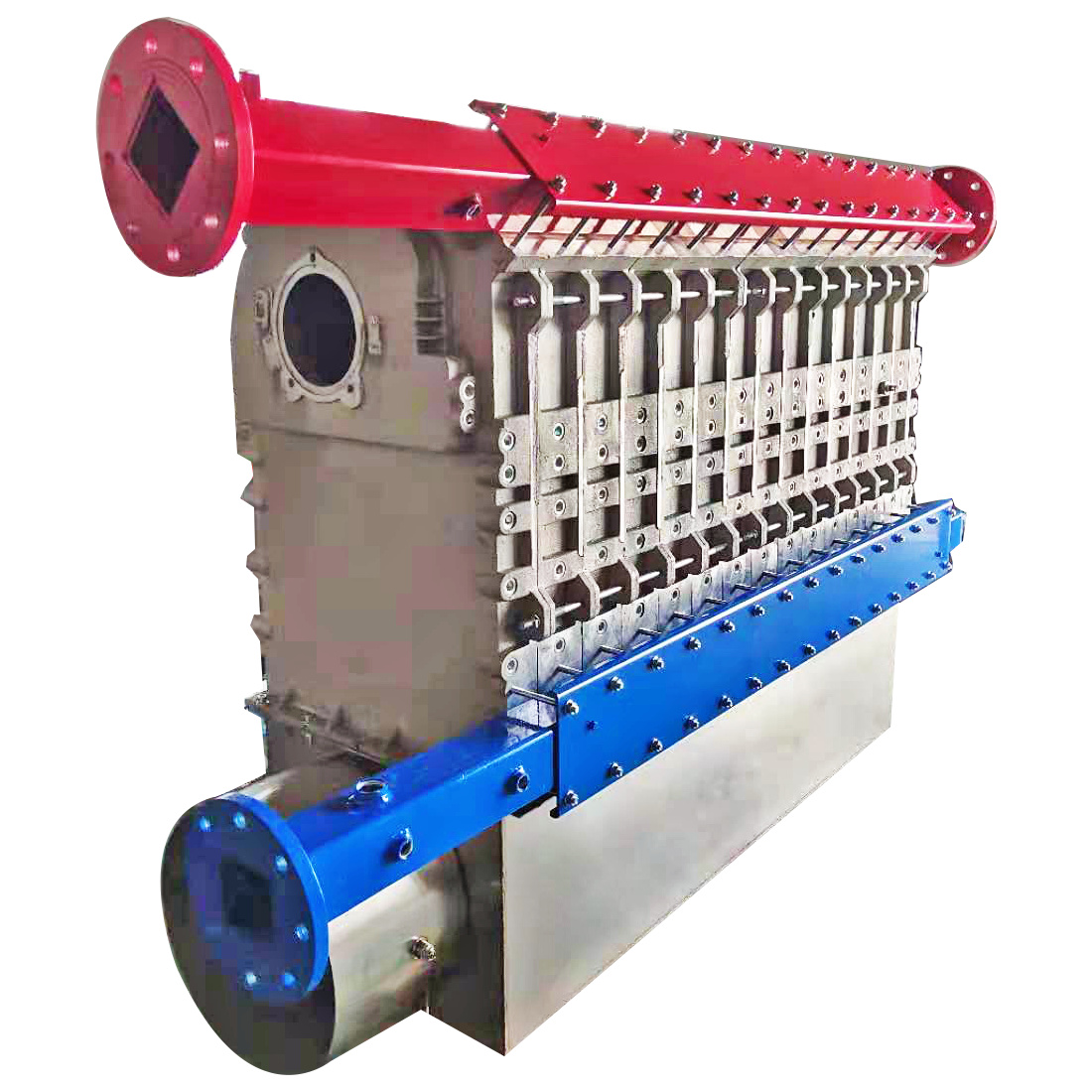

500Kw~700Kw Heat Exchanger |

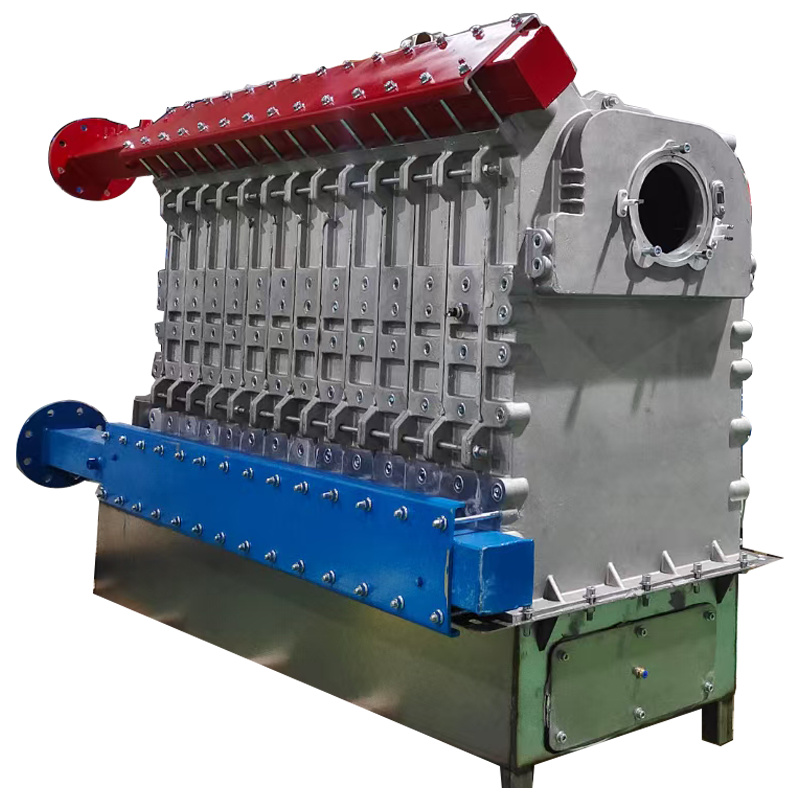

1100Kw~1400Kw Heat Exchanger |

2100Kw Heat Exchanger |