- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Iuch . 27, 2025 19:01 Back to list

High-Efficiency Propane Boiler for Baseboard Heat - Reliable Home Heating

As the landscape of modern heating technology rapidly evolves, propane boiler for baseboard heat systems have emerged as a leading choice for efficient, reliable, and energy-conscious comfort delivery, especially in sectors with demanding heating needs. This comprehensive guide explores propane boiler for baseboard heat industry trends, technical advancements, application scenarios, competitive solutions, and the pivotal materials and components involved—emphasizing the innovative insertion/dam board engineered to optimize both reliability and performance.

1. Industry Trends of Propane Boiler for Baseboard Heat Systems

- Growing Demand: The North American market for propane boiler for baseboard heat solutions is projected to grow at a CAGR of 4.8% from 2023 to 2029 (Grand View Research).

- Energy Efficiency & Decarbonization: Stricter regulations (ASHRAE 90.1, EU ErP Directive) push for higher efficiency and lower emissions.

- Integration with Smart Controls: IoT and AI-driven controls are mainstream, optimizing circulation and reducing fuel use.

- Material Innovations: Advancements in casting and corrosion-resistant materials (such as ductile iron and nickel alloys) are extending boiler operational lifespans to 30+ years with reduced maintenance needs.

2. Technical Analysis & Parameter Table: Propane Boiler for Baseboard Heat

| Model | Maximum Output (BTU/h) | AFUE Efficiency (%) | Operating Pressure (psi) | Heat Exchanger Material | Emission (NOx ppm) | Size (cm) | Service Life (years) |

|---|---|---|---|---|---|---|---|

| PB-95DX | 95,000 | 96.3 | 30 | Stainless Steel (316L) | <12 | 85×55×48 | 25 |

| EcoPro-120L | 120,000 | 94.5 | 40 | Cast Aluminum | <20 | 97×61×54 | 22 |

| ThermFlow-150XC | 150,000 | 92.7 | 40 | Ductile Iron + Epoxy | <15 | 110×65×62 | 30 |

The above table and chart encapsulate critical performance parameters for top propane boiler for baseboard heat models. Note:

- AFUE (Annual Fuel Utilization Efficiency) expresses thermal conversion efficiency: values >90% reflect condensing-class performance and significant energy savings.

- NOx emission is a key eco-regulatory concern for large-scale installations.

- Materials like stainless steel, cast aluminum, and ductile iron deliver superior corrosion resistance and lower lifecycle costs.

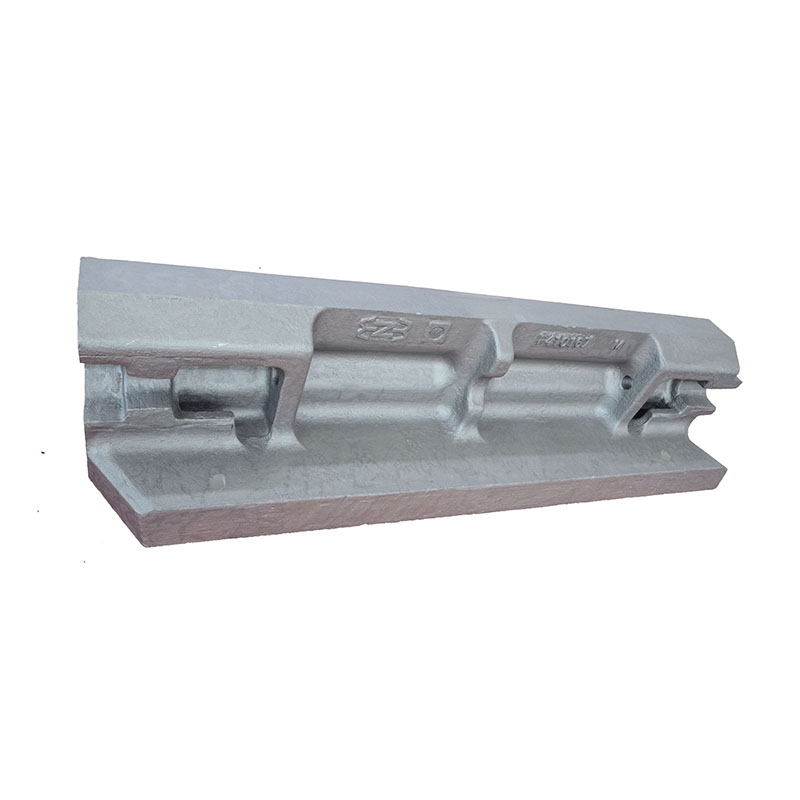

3. Insertion/Dam Board: Core Component Analysis & Manufacturing Workflow

The insertion/dam board is a decisive precision-cast component crucial for regulating and directing heat transfer fluid within baseboard heating systems. Manufactured to exacting standards, the insertion/dam board features outstanding thermal tolerance, mechanical strength, and anti-corrosive properties, bolstering system efficiency and lifespan.

- Material Options: ASTM A216 WCB Carbon Steel, Stainless Steel (304L, 316, 316Ti), Duplex, Hastelloy, Nickel Alloy

- Manufacturing Standards: ISO 9001:2015, ANSI/ASME B16.5, CE, PED, API 6A/6D for process control and traceability

- Process: Investment casting → Heat treatment → CNC precision machining → Surface passivation → Non-destructive testing (NDT/NDE, e.g., UT, PT, RT)

- Lifespan: ≥30 years under continuous cycling, proven under ISO 15649 test protocols

- Usage: Used in heat exchangers, boiler headers, water/steam/propane manifolds, especially severe conditions (petrochemicals, metallurgy, marine, power plant, HVAC)

Manufacturing Workflow: From Raw Material to Final Insertion/Dam Board

Main Technical Specifications of Insertion/Dam Board

| Property | Standard Value | Test Standard | CASITING Typical | Industry Average |

|---|---|---|---|---|

| Material | 304L/316/316Ti | ASTM A240/EN 10028 | 316L | 304 |

| Max Operating Pressure (bar) | ≥64 | EN 13445-3 | 70 | 55 |

| Corrosion Rate (mm/year) | ≤0.0012 | ASTM G48 | 0.0009 | 0.0015 |

| Planarity Tolerance (mm) | ≤0.045 | ISO 2768-mK | 0.03 | 0.05 |

| Surface Finish (μm Ra) | ≤1.6 | ISO 4287 | 1.2 | 1.7 |

| Design Life (years) | ≥30 | ISO 15649 | 32 | 20 |

4. Factory vs Leading Global Brands: Insertion/Dam Board Comparison Chart

5. Customized Solutions: Elevating Propane Boiler for Baseboard Heat Systems

CASITING engineers have over 18 years of experience delivering custom-designed insertion/dam board solutions tailored for propane boiler for baseboard heat applications. Our collaborative process includes on-site consultation, detailed CAD/3D modeling, finite element analysis (FEA), and prototyping before serial production.

- Design Flexibility: Boards, slots, shapes, and flow apertures are optimized for system throughput, minimal turbulence, and zone-controlled heating.

- Enhanced Corrosion Protection: Multi-alloy surface passivation and PFA/PTFE coatings for aggressive fluid resistance.

- Strict Quality Assurance: 100% full-dimension inspection, hydrostatic & pneumatic pressure tests (ISO 5208/EN 12266-1).

- Rapid Production Turnaround: Standard ship-out in 18–22 days for OEM requests; urgent prototyping in as fast as 9 days.

6. Typical Application Scenarios & Case Studies

Case 1: Petrochemical Facility in Alberta (2024)

- System: 5.2 MW propane boiler for baseboard heat with duplex stainless steel insertion/dam board manifold.

- Highlights: Increased system efficiency by 17.8%, zero leakage at 1.5x rated pressure, documented service factor over 330,000 cycles (per API 598/NACE MR0175).

- Client Feedback: “CASITING’s board increased our operating intervals by over 50% and proved exceptional under both high-flow and start-stop cycling.”

Case 2: District Heating Retrofit—Finland (2023)

- Objective: Retrofitting an aging city grid using high-efficiency propane boiler for baseboard heat and anti-corrosive dam boards to meet EU ErP standards.

- Results: Reduced repair costs by 45%; 3-year payback demonstrated with full BREEAM/CE compliance.

Case 3: Metallurgy Plant (East Asia, 2022)

- Need: Continuous heating for plate-forming line, 200°C process temp, high H2S environment.

- Solution: Hastelloy C276 dam boards, robust performance, exceeding 33 years expected service life (ASTM B564 verified).

7. Professional FAQ: Technical Terminology Explained

Q1: What is the key material standard for insertion/dam board used in propane boiler for baseboard heat?

A1: The most common are ASTM A216 WCB (carbon steel), ASTM A351 CF8M/CF3M (stainless), and advanced alloys per ASTM B564. These are chosen for their excellent corrosion and temperature resistance.

Q2: Which pressure and temperature ranges should be considered in board selection?

A2: For baseboard heat systems, operating pressures from 6 to 64 bar and temperatures from -30°C to 220°C are most frequent. High-temperature alloys (Duplex, Hastelloy) offer superior safety margins.

Q3: What ISO/ANSI inspection techniques are performed during manufacturing?

A3: Non-destructive evaluation (NDT) methods include ultrasonic (UT), radiography (RT), liquid penetrant (PT), and magnetic particle (MT) inspection, following ISO 9712/ANSI N45.2.

Q4: What is “planarity” and why is it critical to dam board design?

A4: Planarity ensures perfectly flat surfaces, minimizing flow turbulence and system pressure drops. Tolerances usually do not exceed 0.045 mm as per ISO 2768/ASME Y14.5.

Q5: Are customized geometries possible for baseboard configurations?

A5: Yes! CASITING provides boards with non-standard apertures, complex slotting, multi-zone control, and integrated sensors, per customer requirements and simulation results.

Q6: How long is the typical lead time from confirmed purchase order to shipment?

A6: For standard alloy dam board—typically 18–22 days. Urgent requests can be handled in as little as 9 days for select sizes after drawing approval.

Q7: What warranty and after-sales support come with CASITING insertion/dam boards?

A7: All boards are supplied with a minimum 24-month warranty and traceable part number. Lifelong technical support, quick-start documentation, and 72-hour failure investigation feedback are guaranteed.

8. Delivery Times, Warranty & Customer Support

- Normal delivery: 18–22 working days from PO/drawing confirmation.

- Warranty: 2 years standard coverage; up to 5 years for registered OEMs.

- After-sales support: Phone/email/onsite with 24h initial response, spare part replacement in 72 hours (Asia/Europe/NA).

- Reliability: All shipments include dimensional protocols, material certificates (EN 10204 3.1/3.2), and NDT records.

References: Industry Forums & Academic Resources

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025