- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ធ្នូ . 20, 2024 18:32 Back to list

copper sand casting factory

The Emergence of Copper Sand Casting Factories

In recent years, copper sand casting has emerged as a crucial process in various industries, particularly in manufacturing intricate metal components. This method combines the versatility of sand casting with the unique properties of copper, making it an ideal choice for producing high-quality, durable products. As the demand for copper-based components rises, copper sand casting factories are becoming increasingly prominent in the global market.

Understanding Copper Sand Casting

Copper sand casting is a process that involves pouring molten copper into a sand mold to create specific shapes and designs. The sand mold is typically made from a mixture of sand, clay, and water, which allows for flexibility and precision. The advantage of using sand as a mold material lies in its ability to withstand high temperatures and its relatively low cost. Furthermore, the properties of copper, such as its excellent thermal and electrical conductivity, resistance to corrosion, and malleability, make it an optimal choice for numerous applications.

Applications of Copper Sand Casting

The applications of copper sand casting span across various sectors, including electrical, automotive, plumbing, and art. In the electrical industry, components like connectors and switches are often manufactured using this technique, benefiting from copper's superior conductivity. In automotive manufacturing, copper sand casting is utilized to produce engine components, radiators, and other parts that require high strength and thermal resistance.

In plumbing, copper components such as fittings and valves are essential due to their resistance to corrosion, ensuring a longer lifespan for plumbing systems. Additionally, artists and sculptors are increasingly turning to copper sand casting to create sculptures and decorative items, allowing for detailed designs and intricate patterns.

Advantages of Copper Sand Casting Factories

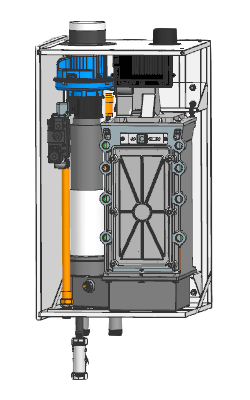

copper sand casting factory

Copper sand casting factories play a pivotal role in streamlining the manufacturing process. One of the most significant advantages of these factories is their ability to produce complex shapes with high precision. Advanced mold-making techniques enable manufacturers to create intricate designs that cater to specific client requirements without compromising quality.

Moreover, copper sand casting factories are often equipped with modern technology and skilled workforce, enhancing productivity and efficiency. The use of computer-aided design (CAD) software and computer numerical control (CNC) machines allows for a faster production cycle while maintaining high accuracy. This technological integration not only minimizes material waste but also leads to cost-effective manufacturing processes.

Environmental Considerations

As industries become increasingly aware of their environmental impact, copper sand casting factories are adopting more sustainable practices. Many factories are implementing recycling systems for sand and metal, reducing waste and conserving resources. Additionally, the use of eco-friendly materials in the mold-making process contributes to minimized environmental harm.

The Future of Copper Sand Casting

The future of copper sand casting factories appears promising as demand for copper components continues to grow. As industries evolve and seek more innovative solutions for their manufacturing challenges, the versatility, durability, and aesthetic appeal of copper will drive the growth of this sector.

Furthermore, with advancements in technology and materials science, copper sand casting processes are expected to become even more efficient and environmentally friendly. The potential for automation and smart manufacturing practices may reshape the industry, enabling factories to meet increasing demands while adhering to sustainable principles.

In conclusion, copper sand casting factories are becoming integral to modern manufacturing, offering unique solutions across various industries. As technology progresses and the emphasis on sustainability grows, these factories are poised for continued expansion, shaping the future of copper-based manufacturing.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025