- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ធ្នូ . 15, 2024 01:12 Back to list

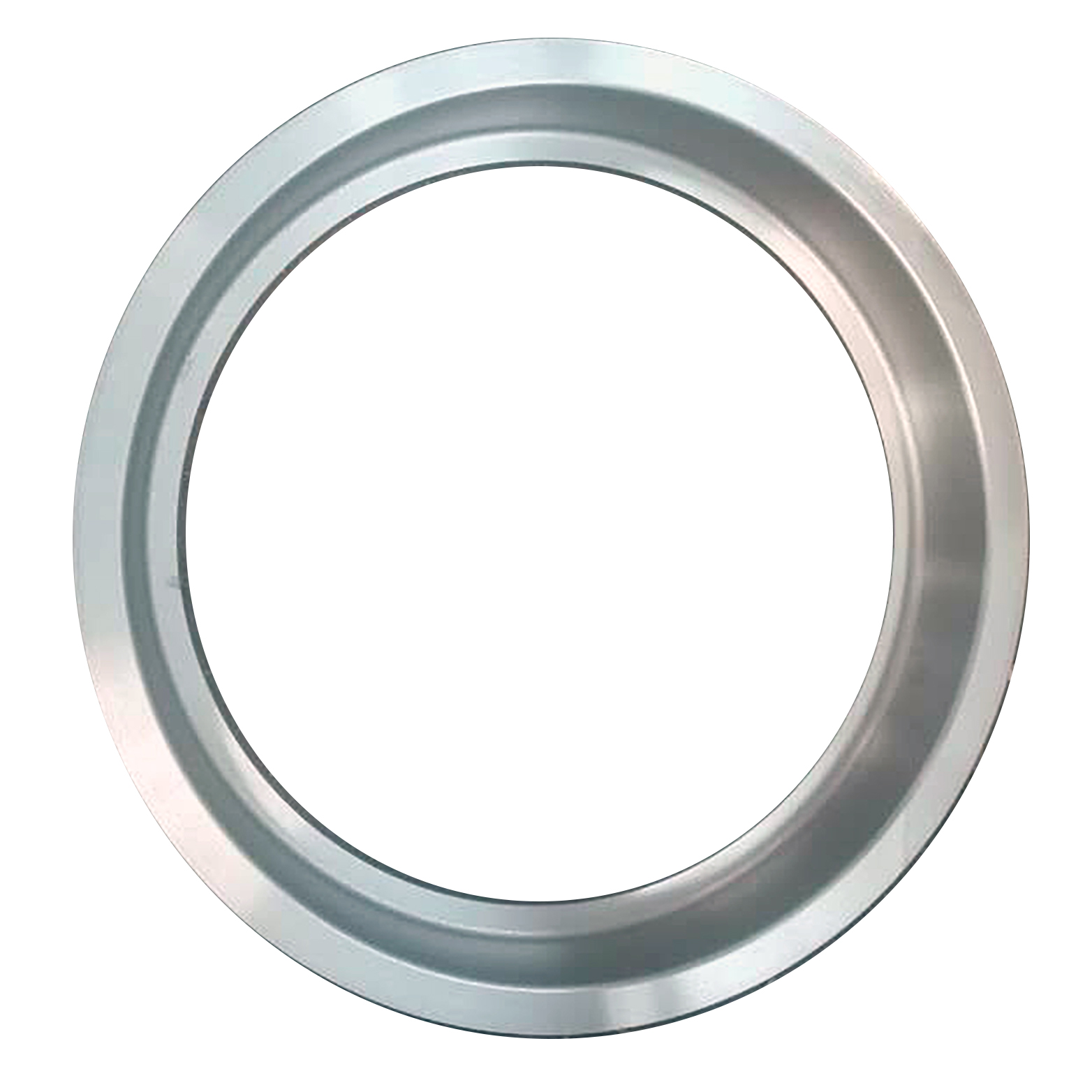

Custom Cement Pipe Mold Pallet for Efficient Manufacturing Solutions and Durability

The Importance of OEM Cement Pipe Mold Pallets in Construction

In the world of construction, efficiency and quality are paramount. One crucial aspect that significantly impacts both factors is the manufacturing process of cement pipes. Cement pipes are essential for various applications, including drainage systems, sewage systems, and water supply lines. To produce high-quality cement pipes, using the right tools and equipment is vital. This is where OEM cement pipe mold pallets come into play.

Understanding OEM Cement Pipe Mold Pallets

OEM, or Original Equipment Manufacturer, refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of cement pipes, OEM cement pipe mold pallets are specially designed molds that ensure the precise shaping and consistency of cement pipes. These pallets are made to fit specific machinery, ensuring compatibility and efficiency in the production process.

Key Benefits of OEM Cement Pipe Mold Pallets

1. Precision Engineering One of the most significant advantages of OEM cement pipe mold pallets is their precision. These pallets are engineered to exact specifications that reflect the desired dimensions and shapes of the finished pipes. This precision leads to a more uniform product, reducing the chances of defects and enhancing the overall quality of the pipes.

2. Durability and Longevity OEM cement pipe mold pallets are constructed from high-strength materials that are designed to withstand the rigors of cement production. Their durability translates into a longer life span, which reduces the frequency of replacements. When manufacturers invest in high-quality pallets, the overall production cost is lowered in the long run due to fewer replacements and repairs.

oem cement pipe mold pallet

3. Improved Production Efficiency The use of OEM pallets can significantly enhance production efficiency. The molds are designed to facilitate quicker curing times and easier demolding processes. As a result, manufacturers can produce more pipes in a shorter period, ultimately boosting their operational efficiency.

4. Customization Options Many OEM suppliers offer customization options to cater to specific client needs. Whether it’s adjustments to dimensions, materials used, or unique designs, the availability of customizable pallets ensures that manufacturers can meet diverse market demands effectively.

5. Cost-Effectiveness Although initial investments in OEM cement pipe mold pallets may seem higher than generic alternatives, the long-term benefits outweigh the costs. With enhanced durability, reduced defects, and improved production rates, the overall cost per unit decreases significantly. This cost-effectiveness makes OEM pallets an attractive choice for manufacturers aiming to maximize their profitability.

6. Enhanced Product Quality The end product’s quality is a direct reflection of the manufacturing process. Using OEM cement pipe mold pallets not only improves the pipes' dimensional accuracy but also their surface finish and overall performance. High-quality cement pipes are less likely to fail under pressure or environmental conditions, making them a reliable choice for construction projects.

Conclusion

In conclusion, OEM cement pipe mold pallets play a critical role in the efficient and high-quality production of cement pipes. Their precision, durability, improved production efficiency, customization options, cost-effectiveness, and contribution to product quality make them an indispensable asset for manufacturers in the construction industry. As the demand for reliable cement pipes continues to grow, investing in OEM solutions is a strategic move for manufacturers aiming to stay competitive and achieve excellence in their production processes. The collaboration with experienced OEM suppliers can further enhance the benefits, ensuring that production stays aligned with industry standards and client expectations.

Ultimately, the evolution of cement pipe manufacturing hinges on adopting advanced technologies and high-quality materials, with OEM cement pipe mold pallets standing at the forefront of this movement. By prioritizing such innovations, the construction industry can look forward to a future characterized by efficiency, reliability, and superior infrastructure.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025