- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

നവം . 05, 2024 08:48 Back to list

aluminum die casting factories

The Rise of Aluminum Die Casting Factories

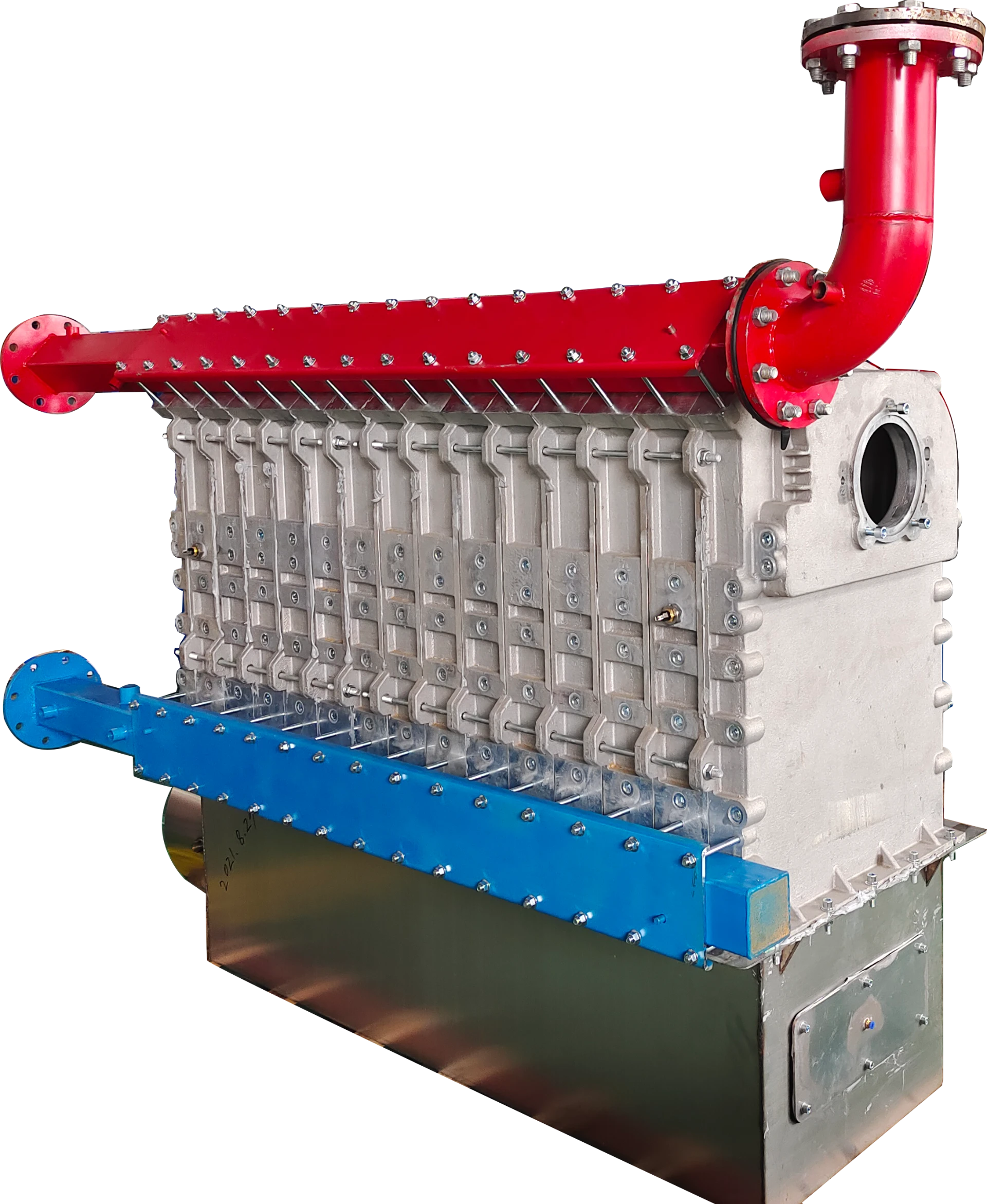

Aluminum die casting has become a cornerstone of modern manufacturing, contributing significantly to various industries such as automotive, aerospace, electronics, and consumer goods. The process involves injecting molten aluminum into a mold under high pressure, producing intricate and precise components with excellent surface finishes. As demand for lightweight and durable materials grows, the emergence of aluminum die casting factories has transformed the landscape of metal fabrication.

The Advantages of Aluminum Die Casting

One of the most compelling reasons for the rising popularity of aluminum die casting is the unique properties of aluminum itself. This lightweight metal not only reduces the overall weight of end products but also enhances their strength-to-weight ratio. As industries increasingly seek to enhance fuel efficiency and reduce carbon footprints, aluminum die casting has emerged as a solution that meets these environmental considerations.

Moreover, aluminum die casting is renowned for its ability to produce complex shapes and designs with tight tolerances. This precision reduces the need for secondary machining processes, thereby lowering production costs and time. The high production rate associated with die casting makes it an efficient choice for manufacturers looking to scale their operations.

The Growth of Aluminum Die Casting Factories

The globalization of supply chains and increasing outsourcing practices have led to the establishment of numerous aluminum die casting factories across the globe. Countries with a strong industrial base, such as China, India, and Germany, have emerged as key players in this sector. The shift toward developing countries has been driven by lower labor costs, abundant raw materials, and expanding manufacturing capacity.

These factories are typically equipped with advanced technology and machinery, enabling them to meet the growing demands of various industries. Automated die casting machines, robotic arms for handling components, and computer-aided design (CAD) software are just a few examples of how technology is enhancing production capabilities. The integration of Industry 4.0 concepts—such as IoT and data analytics—has also improved operational efficiency and quality control.

aluminum die casting factories

Sustainable Practices in Aluminum Die Casting

Sustainability is a significant concern for today's manufacturing sectors, and aluminum die casting factories are not immune to these pressures. Many factories have adopted eco-friendly practices to reduce their environmental impact. For instance, the recycling of aluminum scrap is a common practice in die casting facilities. In fact, aluminum can be recycled indefinitely without losing its properties, making it a sustainable choice for manufacturers.

Additionally, advances in technology have enabled factories to optimize energy consumption and reduce waste during the production process. Innovative cooling techniques, energy-efficient machinery, and waste recycling systems contribute to greener manufacturing practices, aligning with global sustainability goals.

Future Prospects

The future of aluminum die casting factories appears bright as industries continue to seek lightweight and durable materials for various applications. With the automotive sector transitioning toward electric vehicles (EVs), the demand for aluminum components is set to rise. EVs require efficient thermal management solutions, and aluminum die casting has the potential to fulfill this need efficiently.

Furthermore, the integration of additive manufacturing techniques—like 3D printing—into die casting processes may offer new opportunities for customization and production capabilities. As factories innovate and adopt new technologies, they will be better positioned to meet the dynamic needs of modern consumers.

Conclusion

Aluminum die casting factories play a crucial role in the evolution of manufacturing, driven by the material's unique advantages and the industry's shift towards sustainability. With advancements in technology and a focus on efficiency, these factories can meet the diverse needs of various sectors, paving the way for innovation and growth. As we look toward the future, it is clear that the aluminum die casting industry will continue to be integral to the global manufacturing landscape, providing lightweight, durable, and sustainable solutions for generations to come.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025