- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

നവം . 23, 2024 17:21 Back to list

Cast Steel Cement Pipe Mould Pallet Manufacturing Factories Overview and Insights

The Importance of Cast Steel Cement Pipe Mould Pallets in Manufacturing

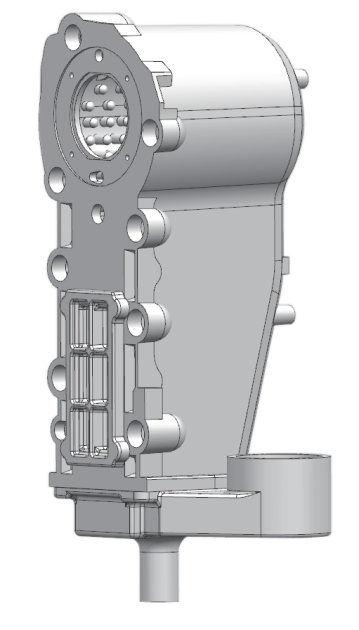

In the realm of infrastructure development and construction, the production of concrete pipes plays a crucial role. These pipes are essential for various applications, including water supply, drainage, and sewage systems. To facilitate the efficient production of these concrete pipes, the casting process is vital, and this is where cast steel cement pipe mould pallets come into play. These pallets serve as the foundation for the creation of high-quality concrete pipes, and their significance cannot be overstated.

What are Cast Steel Cement Pipe Mould Pallets?

Cast steel cement pipe mould pallets are heavy-duty plates designed to support the moulds used in the casting of concrete pipes. Made from high-quality cast steel, these pallets are engineered to withstand the substantial weight and pressure exerted during the casting process. They provide a stable and durable surface for moulds, ensuring that the pipes produced are uniform in shape and high in quality.

The use of cast steel in manufacturing these pallets is a significant advantage. Cast steel offers superior strength compared to alternatives like aluminum or plastic, which may not be able to endure the rigorous demands of concrete casting. Additionally, cast steel pallets are less prone to wear and tear, leading to longer service life and cost savings for manufacturers.

Advantages of Using Cast Steel Cement Pipe Mould Pallets

1. Durability The inherent strength of cast steel ensures that pallets can withstand the heavy loads associated with concrete casting. They resist cracking and deformation, which can compromise the quality of the final product.

2. Precision The smooth surface of cast steel pallets allows for precise moulding. This precision is critical in ensuring that the concrete pipes meet industry standards and specifications.

3. Cost-Effectiveness Although the initial investment in cast steel pallets may be higher than other materials, their longevity reduces the need for frequent replacements. Over time, this leads to lower operational costs.

4. Ease of Maintenance Cast steel pallets require minimal maintenance. Regular cleaning and occasional inspections are typically sufficient to keep them in optimal working condition, ensuring that manufacturers can focus more on production than maintenance.

5. Versatility These pallets can be designed to fit various mould sizes and shapes, making them suitable for different types of cement pipes. This versatility allows manufacturers to adapt quickly to changing production needs or market demands.

cast steel cement pipe mould pallet factories

The Manufacturing Process of Cast Steel Cement Pipe Mould Pallets

The production of cast steel cement pipe mould pallets involves several steps

1. Design and Engineering Manufacturers begin by designing pallets that meet specific requirements. This includes dimensions, weight capacity, and compatibility with existing moulds.

2. Material Selection High-quality cast steel is sourced to ensure that the pallets will perform effectively. The selection of raw materials is crucial for the overall strength and durability of the pallets.

3. Casting The selected steel is melted and poured into moulds to form the shape of the pallets. This step requires precision to ensure consistency and quality in the final product.

4. Finishing After the pallets cool and solidify, they undergo finishing processes like grinding and polishing. This ensures a smooth surface that minimizes friction during the casting of concrete.

5. Quality Control Each pallet is subjected to rigorous quality control measures to verify strength, durability, and dimensions. Only pallets that meet these stringent standards are approved for use.

Conclusion

As the demand for concrete pipes continues to rise worldwide, the role of cast steel cement pipe mould pallets in the manufacturing process becomes increasingly important. Their durability, precision, and cost-effectiveness make them an essential investment for companies looking to produce high-quality concrete pipes efficiently and reliably.

By choosing cast steel cement pipe mould pallets, manufacturers not only enhance their production capabilities but also contribute to the overall quality and sustainability of the infrastructure projects that rely on these vital components. In a competitive market, utilizing superior materials and technologies will ultimately lead to success and growth in the manufacturing sector.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025