- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

നവം . 24, 2024 08:29 Back to list

low nitrogen condensing natural gas fired boiler factories

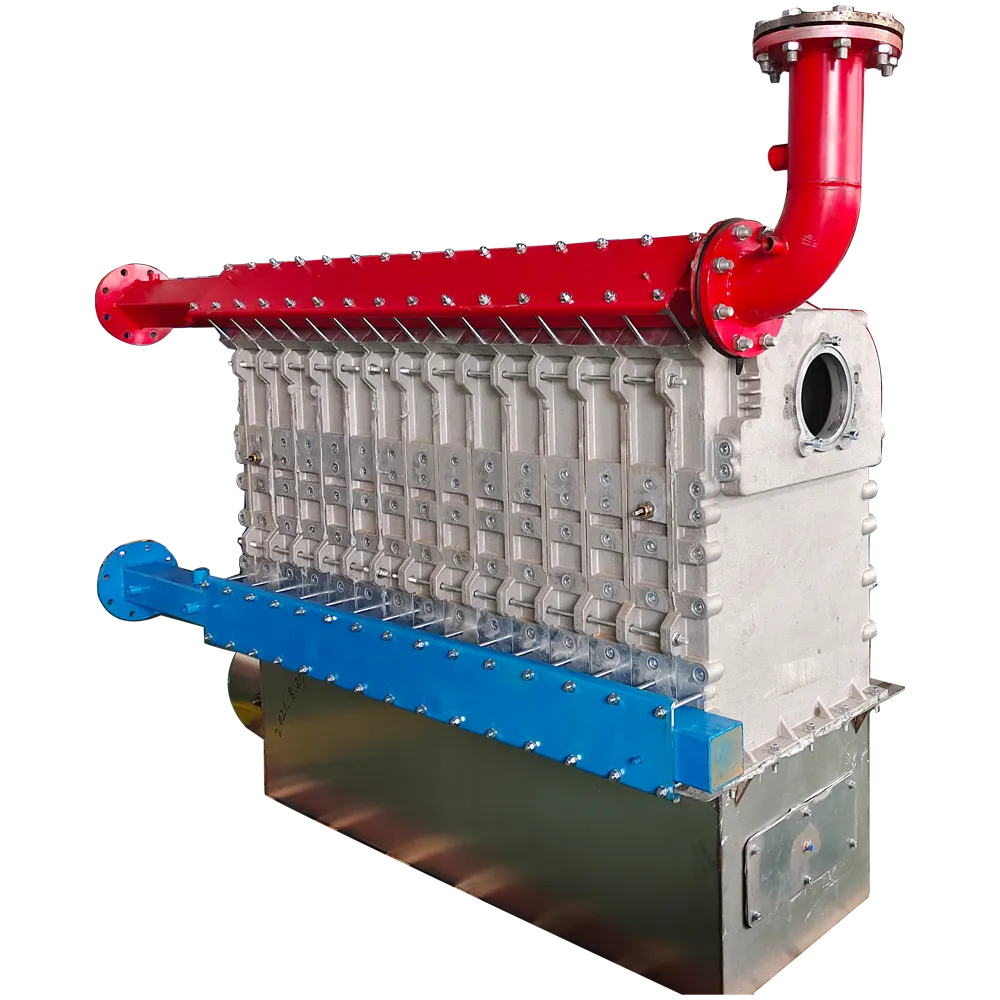

The Rise of Low Nitrogen Condensing Natural Gas Fired Boilers in Industrial Manufacturing

In recent years, the focus on environmental sustainability and energy efficiency has led to significant advancements in boiler technology, particularly in the realm of low nitrogen condensing natural gas fired boilers. As industries face increasing pressure to reduce their carbon footprint, these innovative systems have emerged as a solution, combining efficiency with lower emissions, thus revolutionizing the boiler manufacturing landscape.

Natural gas is recognized as a cleaner alternative to other fossil fuels. However, the combustion of natural gas still produces nitrogen oxides (NOx), which are harmful pollutants contributing to smog and respiratory problems. Traditional boilers can emit significant amounts of these gases, prompting the need for improved designs that minimize NOx emissions. This has spurred the development of low nitrogen condensing boilers, which harness advanced technologies to achieve lower emissions while maximizing fuel efficiency.

The key to low nitrogen condensing boilers lies in their unique design and operational principles. These boilers are equipped with a condensing heat exchanger that recovers heat from the flue gases. By condensing water vapor back into liquid, they reclaim latent heat, which would otherwise be lost in conventional systems. This process not only enhances efficiency but also reduces the operating temperature of the exhaust gases, leading to lower NOx emissions. Many manufacturers have adopted cutting-edge materials and engineering practices that enhance the durability and performance of these boilers, ensuring they withstand the rigors of industrial applications.

low nitrogen condensing natural gas fired boiler factories

As factories and manufacturers seek to comply with more stringent environmental regulations, the adoption of low nitrogen condensing natural gas fired boilers is becoming increasingly popular. Industries such as food processing, pharmaceuticals, and textiles, which require significant amounts of steam and hot water, are particularly benefiting from these advanced systems. The integration of these boilers not only helps in meeting regulatory standards but also significantly reduces energy costs over time.

Cost efficiency is a vital consideration for any manufacturing operation. Although the initial investment in low nitrogen condensing boilers can be higher than traditional systems, the long-term savings in energy consumption and maintenance often justify the expenditure. With the growing trend of sustainability in business practices, many manufacturers are willing to invest in these advanced systems to enhance their operational efficiency and corporate responsibility.

Furthermore, technological advancements continue to improve the viability of low nitrogen condensing boilers. Innovations such as smart controls, modulators, and predictive maintenance tools are becoming integral in optimizing boiler performance, leading to even greater reductions in energy use and emissions. As more factories adopt these smart solutions, the overall efficiency of manufacturing processes can improve dramatically.

In conclusion, low nitrogen condensing natural gas fired boilers represent a significant advancement in industrial boiler technology. By reducing NOx emissions and increasing energy efficiency, these systems are not only beneficial for the environment but also offer economic advantages for manufacturers. As industries continue to prioritize sustainability, the demand for such innovative solutions is set to rise, marking a new era in boiler manufacturing that aligns with global efforts to combat climate change.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025