- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 20, 2024 02:44 Back to list

Custom pipe mould pallet manufacturer.

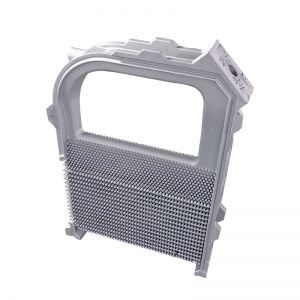

The Art of Punching Pipe Mould Pallets A Manufacturer's Perspective

In the intricate world of industrial manufacturing, the creation of precise and durable components is paramount. One such essential component is the punching pipe mould pallet, a specialized tool that plays a critical role in the production process. As a manufacturer specializing in these tools, our commitment to excellence is reflected not only in the products we create but also in the innovative techniques and materials we employ.

Punching pipe mould pallets are designed to withstand the rigors of high-pressure environments where pipes are formed and shaped. These pallets must be able to endure significant force without warping or cracking, ensuring that each pipe produced meets stringent quality standards. To achieve this level of durability, we utilize high-grade steel alloys and advanced metallurgical processes that enhance the strength and longevity of our moulds.

Our manufacturing process begins with a deep understanding of our clients' specific needs. Each mould is custom-designed to accommodate varying pipe dimensions and specifications. This bespoke approach ensures that our clients receive tools tailored perfectly to their unique operations.

In crafting these precision instruments, we employ state-of-the-art computer-aided design (CAD) software to create blueprints with exacting tolerances. Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision

Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision punching pipe mould pallet manufacturer. The result is a product that fits seamlessly into our clients' production lines, reducing downtime and increasing efficiency.

But the innovation doesn't stop at the design and fabrication stages. We also pay meticulous attention to the finishing processes. Our punching pipe mould pallets undergo surface treatments such as nitriding or carbonitriding to improve their hardness and wear resistance. These treatments extend the lifespan of the tools, allowing them to withstand thousands of punching cycles without degrading performance.

Moreover, we stay at the forefront of environmental responsibility by implementing sustainable practices throughout our manufacturing operations. From recycling waste materials to optimizing energy consumption, our efforts contribute to a greener industrial footprint while maintaining the integrity of our products.

In conclusion, the manufacture of punching pipe mould pallets is a testament to the confluence of engineering prowess, technological advancement, and customer-centric philosophies. As a leading manufacturer, we pride ourselves on delivering tools that not only meet but exceed industry standards—tools that help our clients shape their future with confidence and reliability.

punching pipe mould pallet manufacturer. The result is a product that fits seamlessly into our clients' production lines, reducing downtime and increasing efficiency.

But the innovation doesn't stop at the design and fabrication stages. We also pay meticulous attention to the finishing processes. Our punching pipe mould pallets undergo surface treatments such as nitriding or carbonitriding to improve their hardness and wear resistance. These treatments extend the lifespan of the tools, allowing them to withstand thousands of punching cycles without degrading performance.

Moreover, we stay at the forefront of environmental responsibility by implementing sustainable practices throughout our manufacturing operations. From recycling waste materials to optimizing energy consumption, our efforts contribute to a greener industrial footprint while maintaining the integrity of our products.

In conclusion, the manufacture of punching pipe mould pallets is a testament to the confluence of engineering prowess, technological advancement, and customer-centric philosophies. As a leading manufacturer, we pride ourselves on delivering tools that not only meet but exceed industry standards—tools that help our clients shape their future with confidence and reliability.

Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision

Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision Once the design is finalized, our CNC (Computer Numerical Control) machining centers take over, carving out each mould with microscopic precision punching pipe mould pallet manufacturer. The result is a product that fits seamlessly into our clients' production lines, reducing downtime and increasing efficiency.

But the innovation doesn't stop at the design and fabrication stages. We also pay meticulous attention to the finishing processes. Our punching pipe mould pallets undergo surface treatments such as nitriding or carbonitriding to improve their hardness and wear resistance. These treatments extend the lifespan of the tools, allowing them to withstand thousands of punching cycles without degrading performance.

Moreover, we stay at the forefront of environmental responsibility by implementing sustainable practices throughout our manufacturing operations. From recycling waste materials to optimizing energy consumption, our efforts contribute to a greener industrial footprint while maintaining the integrity of our products.

In conclusion, the manufacture of punching pipe mould pallets is a testament to the confluence of engineering prowess, technological advancement, and customer-centric philosophies. As a leading manufacturer, we pride ourselves on delivering tools that not only meet but exceed industry standards—tools that help our clients shape their future with confidence and reliability.

punching pipe mould pallet manufacturer. The result is a product that fits seamlessly into our clients' production lines, reducing downtime and increasing efficiency.

But the innovation doesn't stop at the design and fabrication stages. We also pay meticulous attention to the finishing processes. Our punching pipe mould pallets undergo surface treatments such as nitriding or carbonitriding to improve their hardness and wear resistance. These treatments extend the lifespan of the tools, allowing them to withstand thousands of punching cycles without degrading performance.

Moreover, we stay at the forefront of environmental responsibility by implementing sustainable practices throughout our manufacturing operations. From recycling waste materials to optimizing energy consumption, our efforts contribute to a greener industrial footprint while maintaining the integrity of our products.

In conclusion, the manufacture of punching pipe mould pallets is a testament to the confluence of engineering prowess, technological advancement, and customer-centric philosophies. As a leading manufacturer, we pride ourselves on delivering tools that not only meet but exceed industry standards—tools that help our clients shape their future with confidence and reliability. Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025