- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 20, 2024 02:45 Back to list

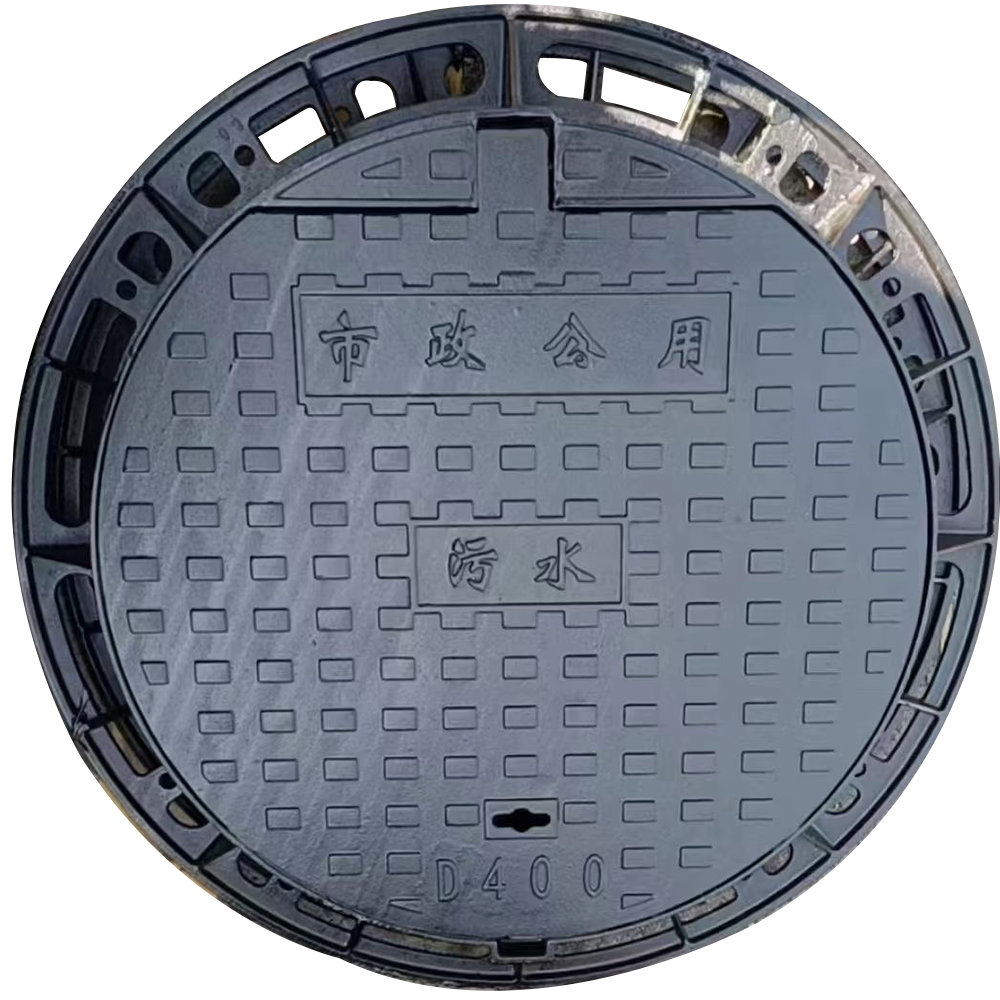

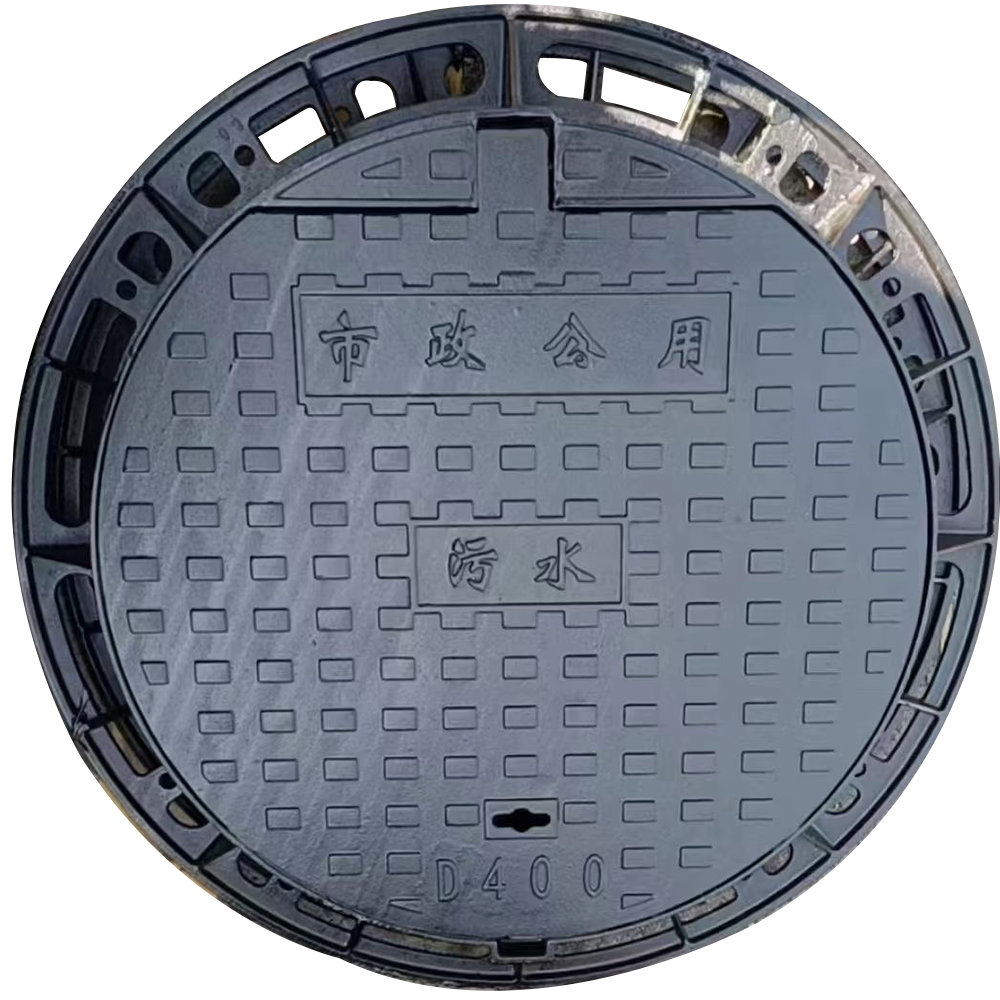

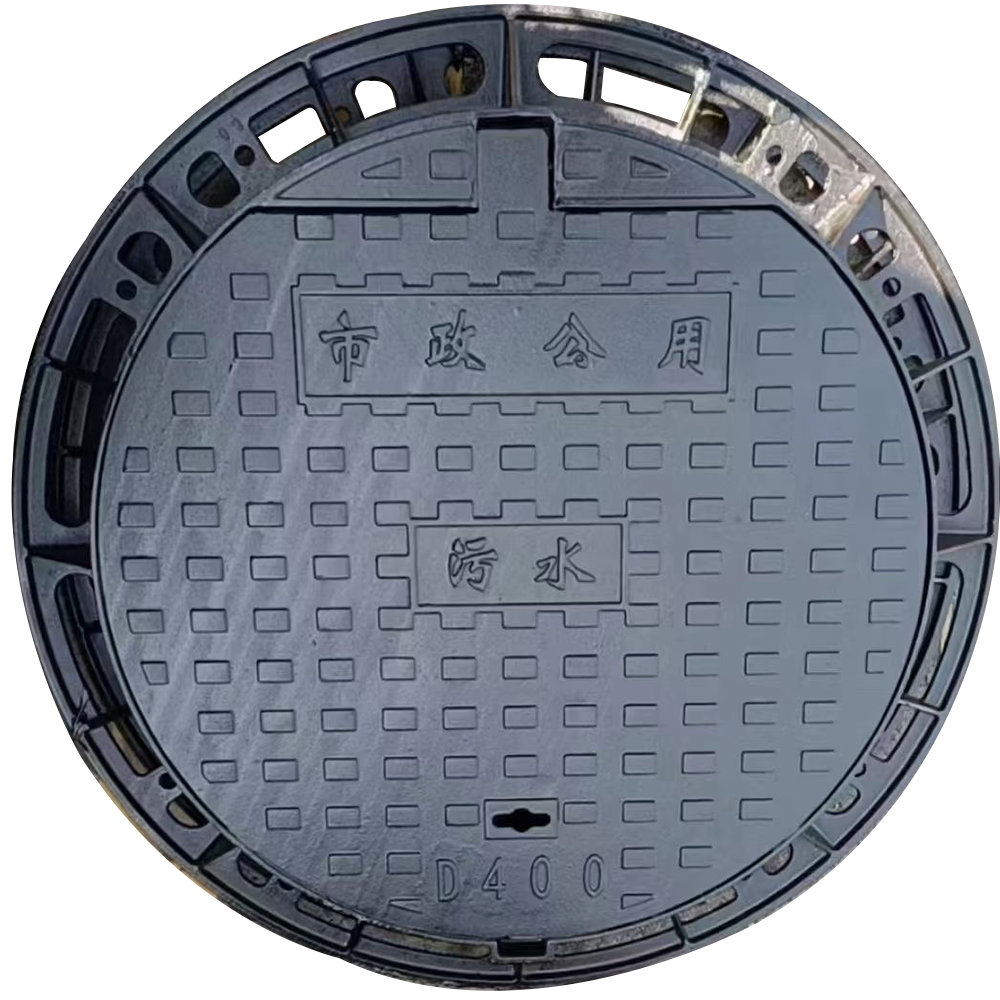

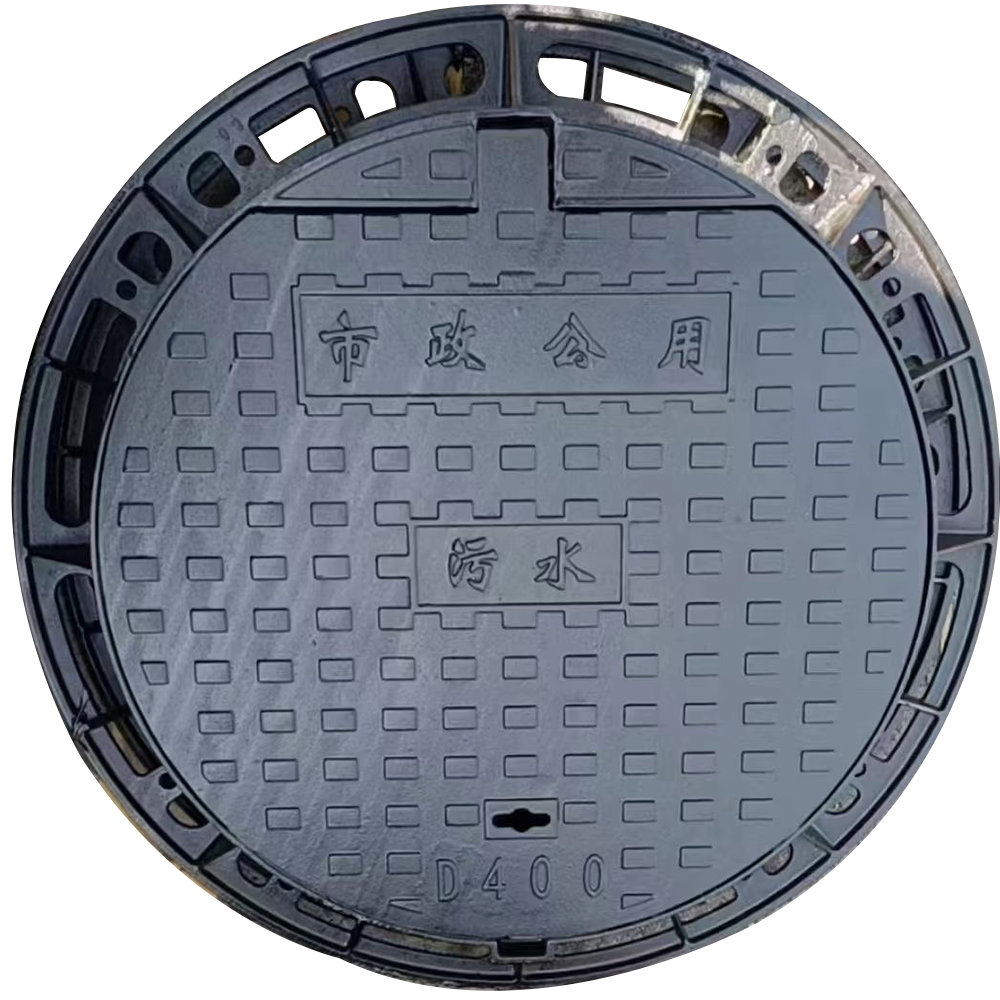

Heavy Steel Casting Strength and Durability.

Heavy Steel Casting The Backbone of Industrial Development

In the vast landscape of industrial manufacturing, heavy steel casting stands as a towering pillar of progress and innovation. This ancient art form involves pouring molten steel into pre-formed molds to create large, sturdy structures that are essential for various industries. From massive machinery components to intricate architectural wonders, heavy steel casting has been instrumental in shaping the modern world.

The process begins with selecting high-quality raw materials, primarily iron ore, which is then melted in giant furnaces at temperatures exceeding 1,500 degrees Celsius. Once the metal reaches its liquid state, it is carefully transferred to a ladle and subsequently poured into a prepared mold. These molds, often made from sand or metal, are designed with precision to ensure the final product's integrity and functionality.

One of the most significant challenges in heavy steel casting is managing the cooling process. Rapid changes in temperature can cause the steel to crack or warp, affecting both the quality and safety of the cast piece. To mitigate this risk, foundries employ advanced technologies such as computer-aided cooling systems that regulate the rate at which the steel cools, ensuring a uniform and controlled solidification.

The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold heavy steel casting. In construction, they provide the skeletal framework for skyscrapers and bridges, offering unparalleled strength and durability. Within the energy sector, cast steel components are used in power plants and oil refineries, where their resilience under extreme conditions is paramount. Additionally, the transportation industry relies on heavy steel castings for train wheels, ship propellers, and other critical parts that must withstand constant use and environmental stressors.

Despite advancements in materials science and alternative manufacturing techniques, heavy steel casting remains a cornerstone of industrial development due to its unique combination of strength, flexibility, and cost-effectiveness. As we look towards a future where sustainability and efficiency become increasingly important, the continued innovation in heavy steel casting processes promises to play a pivotal role in shaping our built environment while minimizing environmental impact.

In conclusion, heavy steel casting is not merely a technique; it is a testament to human ingenuity and the relentless pursuit of progress. Its ability to transform raw materials into monumental structures that endure for generations is a reflection of our capacity to harness nature's forces for the betterment of society. As we move forward, the evolution of heavy steel casting will undoubtedly continue to support the growth of industries and contribute to the development of new technologies that further enhance our quality of life.

heavy steel casting. In construction, they provide the skeletal framework for skyscrapers and bridges, offering unparalleled strength and durability. Within the energy sector, cast steel components are used in power plants and oil refineries, where their resilience under extreme conditions is paramount. Additionally, the transportation industry relies on heavy steel castings for train wheels, ship propellers, and other critical parts that must withstand constant use and environmental stressors.

Despite advancements in materials science and alternative manufacturing techniques, heavy steel casting remains a cornerstone of industrial development due to its unique combination of strength, flexibility, and cost-effectiveness. As we look towards a future where sustainability and efficiency become increasingly important, the continued innovation in heavy steel casting processes promises to play a pivotal role in shaping our built environment while minimizing environmental impact.

In conclusion, heavy steel casting is not merely a technique; it is a testament to human ingenuity and the relentless pursuit of progress. Its ability to transform raw materials into monumental structures that endure for generations is a reflection of our capacity to harness nature's forces for the betterment of society. As we move forward, the evolution of heavy steel casting will undoubtedly continue to support the growth of industries and contribute to the development of new technologies that further enhance our quality of life.

The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold

The applications of heavy steel castings are manifold heavy steel casting. In construction, they provide the skeletal framework for skyscrapers and bridges, offering unparalleled strength and durability. Within the energy sector, cast steel components are used in power plants and oil refineries, where their resilience under extreme conditions is paramount. Additionally, the transportation industry relies on heavy steel castings for train wheels, ship propellers, and other critical parts that must withstand constant use and environmental stressors.

Despite advancements in materials science and alternative manufacturing techniques, heavy steel casting remains a cornerstone of industrial development due to its unique combination of strength, flexibility, and cost-effectiveness. As we look towards a future where sustainability and efficiency become increasingly important, the continued innovation in heavy steel casting processes promises to play a pivotal role in shaping our built environment while minimizing environmental impact.

In conclusion, heavy steel casting is not merely a technique; it is a testament to human ingenuity and the relentless pursuit of progress. Its ability to transform raw materials into monumental structures that endure for generations is a reflection of our capacity to harness nature's forces for the betterment of society. As we move forward, the evolution of heavy steel casting will undoubtedly continue to support the growth of industries and contribute to the development of new technologies that further enhance our quality of life.

heavy steel casting. In construction, they provide the skeletal framework for skyscrapers and bridges, offering unparalleled strength and durability. Within the energy sector, cast steel components are used in power plants and oil refineries, where their resilience under extreme conditions is paramount. Additionally, the transportation industry relies on heavy steel castings for train wheels, ship propellers, and other critical parts that must withstand constant use and environmental stressors.

Despite advancements in materials science and alternative manufacturing techniques, heavy steel casting remains a cornerstone of industrial development due to its unique combination of strength, flexibility, and cost-effectiveness. As we look towards a future where sustainability and efficiency become increasingly important, the continued innovation in heavy steel casting processes promises to play a pivotal role in shaping our built environment while minimizing environmental impact.

In conclusion, heavy steel casting is not merely a technique; it is a testament to human ingenuity and the relentless pursuit of progress. Its ability to transform raw materials into monumental structures that endure for generations is a reflection of our capacity to harness nature's forces for the betterment of society. As we move forward, the evolution of heavy steel casting will undoubtedly continue to support the growth of industries and contribute to the development of new technologies that further enhance our quality of life. Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025